Key Considerations When Selecting a Replacement Vapor Degreaser Cleaning Fluid

Can your preferred choice be dropped in?

by Elizabeth Norwood

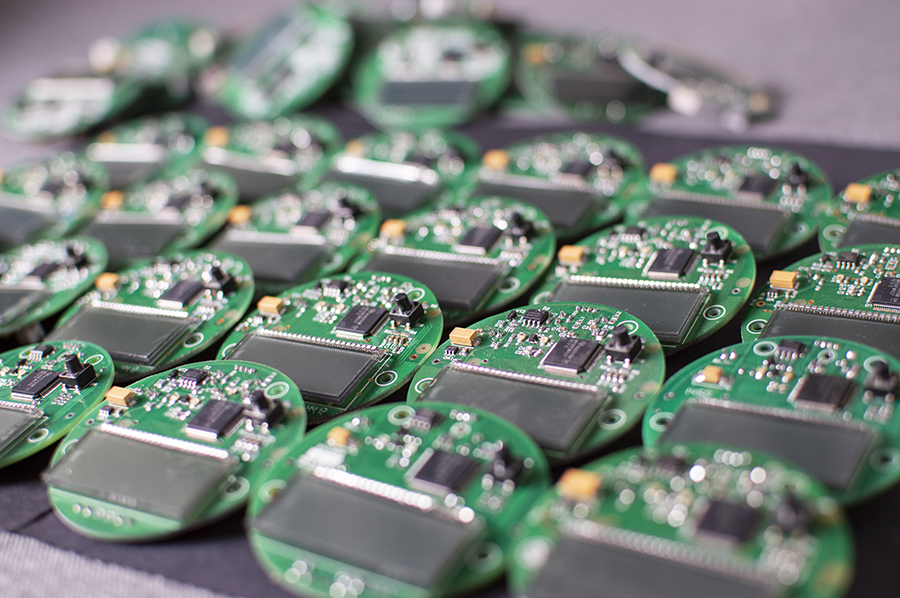

Let’s set the scene. You have been using the same vapor degreasing fluid to successfully clean complex circuitry and printed circuit boards (PCBs) for years, only to learn that your trusted line of cleaning fluids will soon be discontinued. What do you do? How do you choose a replacement that meets the PCB cleaning challenges that you and many other fabricators face?

Factors to consider when choosing a replacement cleaning fluid include the equipment, the substrate being cleaned, the type of contamination being removed, the long-term availability and sustainability of the replacement fluid, and the level of support available from the supplier.

Taking these factors into consideration, PCB manufacturers can make an informed decision and select a replacement cleaning fluid that meets their specific needs while minimizing any negative impact on their cleaning processes.

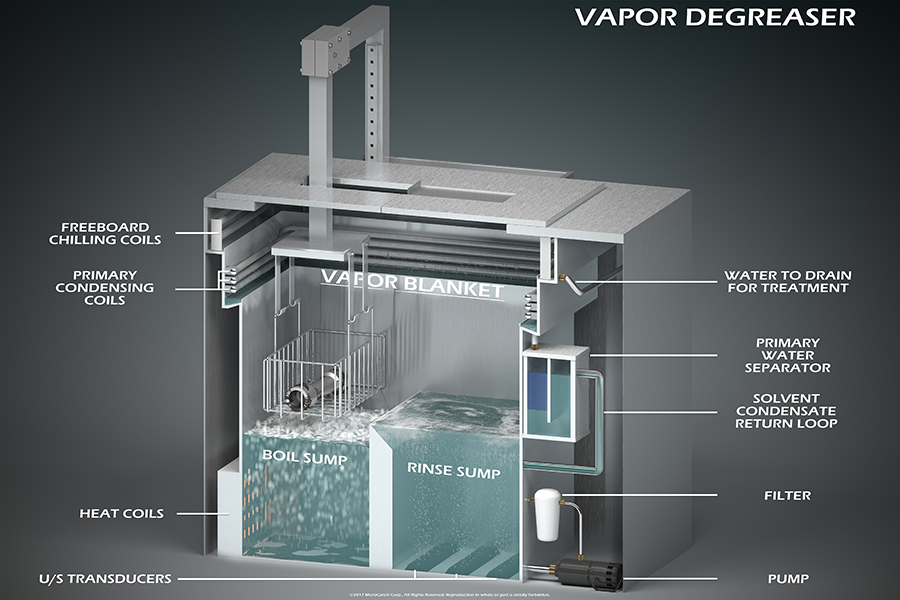

Consider Your Equipment

When looking for a replacement cleaning fluid, manufacturers should first consider the cleaning equipment they use. Manufacturers should ask potential suppliers questions about their cleaning fluid’s compatibility with their equipment and if their equipment will require any upgrades or modifications to use the new fluid.

Many modern, nonflammable and environmentally progressive vapor degreasing fluids can be used in existing equipment, with the same operating methods. After emptying and cleaning the vapor degreaser of the previous fluid, the replacement cleaning fluid can be “dropped in” to the machinery without any significant change to the cleaning process. This means new or extra equipment is not required, with little disruption to production workflow.

It is important that manufacturers start to prepare for their cleaning fluid transition early. Transitioning from one solvent to another may involve testing new cleaning fluids on a small scale to ensure that they are effective and do not cause any damage to equipment or substrates. It may also involve training employees on how to use the new cleaning fluid and adjusting the cleaning process to ensure optimal performance.

Is it Compatible?

It is important to confirm material compatibility and to ensure the replacement vapor degreasing fluid under consideration will not negatively impact the substrate of the parts being cleaned.

Today’s complex electronics are made from various materials, including metals, ceramics and plastics. A cleaning fluid must be strong enough to effectively remove any contamination, yet not cause damage to sensitive PCB materials such as polycarbonate and acrylic.

Modern vapor degreasing fluids offer high enough solvency (or Kb value) to selectively clean contamination, without damaging surfaces or delicate parts. Because modern vapor degreasing fluids are low boiling, they can effectively clean fragile electronics and minimize the risk of damage, especially to wafers and thin PCBs. They come in unique, customizable blends to accommodate many different types of applications. This permits removal of a particular soil from a specific substrate to help maximize cleaning effectiveness without material damage.

Type of Contamination

Cleaning is crucial to the success of most PCBs and must be completed correctly to guarantee the reliability and lifespan of the electronic component. To clean effectively, it is important to identify the contamination first to ensure the selected cleaning fluid will remove it.

Throughout the manufacturing process, PCBs contact all kinds of contaminants that must be removed. These include marking inks, uncured solder paste, adhesives, conformal coatings, and fingerprints. To ensure that PCBs operate without error, these contaminants must be removed.

PCB contamination is categorized into four main groups: insoluble particulate, organics, inorganics and water.

- Insoluble particulate is a polar contaminant that cannot be dissolved by water or a cleaning fluid, for example dust and metal chips. It electrostatically bonds to PCB surfaces and requires a dense electrostatic polar cleaning fluid that contains conductive molecules to break the static bond of the contaminant and displace the particulate.

- Organic or non-polar contaminants include rosin solder pastes and fluxes. Organic contaminants can also include non-polar oils and greases. These can be dissolved and removed with mild to medium strength organic flux removers.

- Inorganic, polar contaminants are the residue left by lead-free and no-clean fluxes and solder pastes and can be extremely difficult to remove. Inorganic contaminants usually require more aggressive flux removers to dissolve contaminants. However, it is important to perform a materials compatibility test before use.

- Water can become trapped in densely populated circuit boards when using an aqueous cleaning system. It is typically removed using air knives, but this may still leave moisture and allow water spots to form. Water contamination can be removed using batch drying inside a vapor degreaser outfitted with a water separator.

When replacing a cleaning fluid, testing is key to ensure the contaminant is successfully removed and the substrate is not affected. To ensure cleaning success, some cleaning fluid manufacturers can conduct on-site audits or in-lab tests with your sample parts. Based on the substrate and the contaminant, they can recommend or engineer the fluids and processes that work best.

Selecting a Cleaning Fluid for the Long-Term

When selecting a replacement cleaning fluid, PCB fabricators should choose one that has been on the market for some time and has a proven record of effectiveness and a long-term sustainability profile. Also, ensure the supplier has the knowledge and vapor degreaser cleaning expertise to support your choice.

Electronics manufacturers should also consider the long-term availability of the chosen fluid. If a fluid is available for a limited time only, it may be challenging to find a replacement when it is needed.

Check a fluid’s sustainability credentials before making a decision. Many newer cleaning fluids are designed to be more environmentally friendly than older ones and benefit from meeting standards like those required by the US Environmental Protection Agency or the EU’s rules of REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals). Some feature a zero ozone-depleting potential (ODP) and low volatile organic compound (VOC) content, as well as having low global-warming potential (GWP), which limit the negative impact on air quality.

Additionally, and importantly, most next-generation debinding fluids are human-safe with better toxicity profiles and higher TLVs (threshold limit values) than legacy fluids – making them less hazardous for exposed workers to use.

Look for a supplier with technical expertise in cleaning a variety of PCB substrates using different cleaning methods and who can perform on-site cleaning audits to identify materials used and the contamination to be removed.

Suppliers with laboratory support structure can aid a smooth transition. Those able to support PCB manufacturers throughout the process, from research and design, to testing and manufacturing, can identify and solve potential cleaning problems before the PCBs even go into production.

Additionally, ensure the company has a longstanding, sound reputation for customer service and can provide technical support, troubleshooting, and training on the new cleaning fluid.

Help is Out There

Knowing a tried and tested cleaning fluid is being discontinued can be concerning. Finding a replacement may seem like an impossible challenge, but effective alternatives exist.

Consider key features including equipment requirements, cleaning ability, substrate compatibility, and environmental sustainability. Work with a supplier that can provide a vapor degreasing fluid that addresses all these challenges with the added benefit of high levels of support and dependability. Once this is all in place, selecting a replacement cleaning fluid is not so daunting.

Elizabeth Norwood is a senior chemist at MicroCare (microcare.com). She has been in the industry more than 25 years and holds a bachelor’s in chemistry from the University of St. Joseph. Norwood researches, develops and tests cleaning-related products. She currently has one patent issued and two pending for her work.