The Heat is On

Claire Wemp is hot on the trail of better thermal interface materials and more engineering roles for women.

by Mike Buetow

Thermal interface materials (TIM) are used between components to help with heat dissipation. Claire Wemp, Ph.D., is a thermal applications engineer at DuPont, with a doctorate in mechanical engineering, where her research was on heat transfer enhancement for metal surfaces. While an undergraduate, Wemp also became involved in the Society of Women Engineers, and continues to work with the nonprofit professional organization today. Wemp joined PCD&F/CIRCUITS ASSEMBLY on the PCB Chat podcast, where she discussed the use of TIMs and her work with SWE. What follows is a lightly edited transcript.

Mike Buetow: We’re going to talk about TIM 1 materials, and it might be confusing for those who don’t know about the TIM 1 and TIM 2 classifications. Do you want to take a moment to explain the difference?

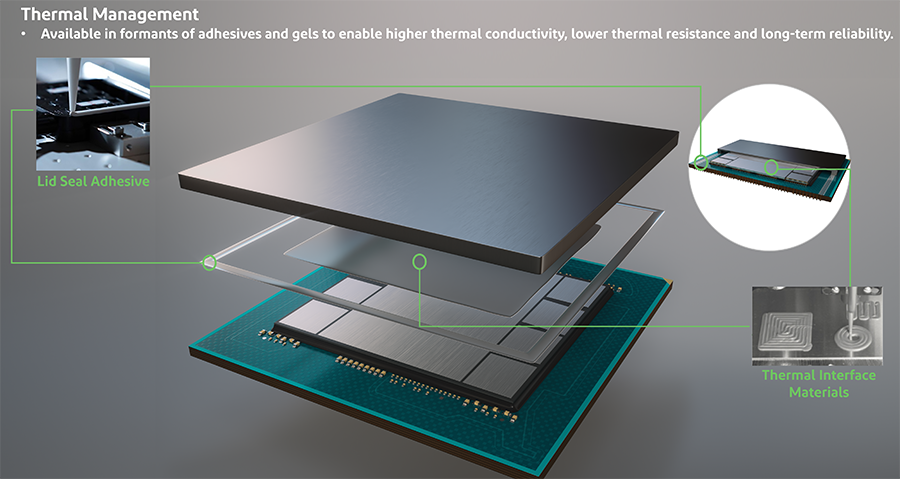

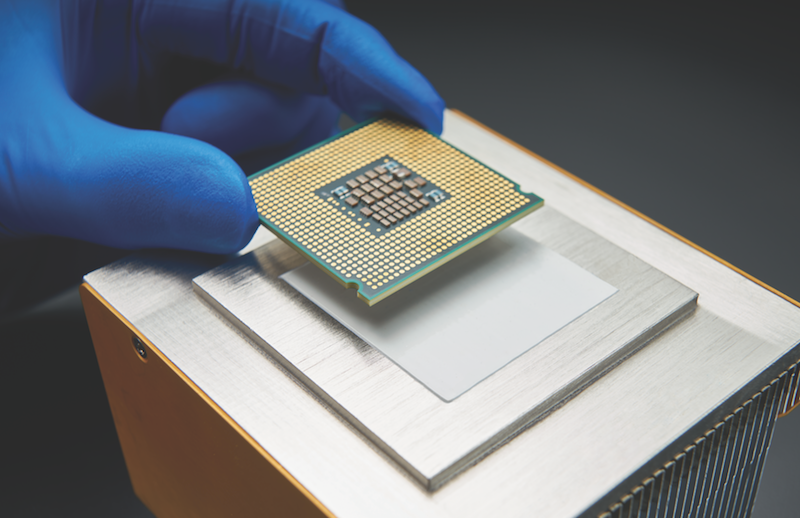

Claire Wemp: Yes, absolutely, Mike. For TIM materials or thermal interface materials, you can think of it like a soft or pliable material that’s placed between the two hard materials to help assist with heat flow going from the heat source out to some sort of heat sink. If we think about a typical computer chip, you’ll have a GPU on your laptop, you’ve got your PCB, you have some sort of silicon wafer that’s attached on, maybe your flip chip design, and then usually there’s some sort of lid that fits over top of that. And at most, if you’re the kind of person that tinkers around with computers, you’re going to be seeing that lid. You might pop off the heat sink or hinge device of some sort, you’re going to see that lid there. And you might actually see a TIM material between the lid and heat sink itself. So when we say TIM 1, we are actually referring to the thermal interface material that is below the lid. So it’s the TIM material that goes between – if it’s a flip chip – the backside of the die – it’s actually touching the silicon – and the lid, which is usually some sort of metal material. It’s kind of a first line of defense direct from the source out to that lid material.

MB: There’s obviously a trend toward reducing heat in electronics by means of lower power devices. I think of Intel’s Atom line of processors, for example, or AMD with the new Zen 4 chips. Can you tell us a bit more about where TIMs fit in? If device manufacturers are trying to take care of some of that simply by introducing lower power devices, what are some of the other hurdles that you have to go through or reasons why you might use TIM in order to get some of that heat transfer or dissipation?

CW: That’s a great question. Lower power devices or just the power in general coming from the device is really only one factor that you would use in selecting the type of TIM or for that matter, as an application engineer, one of my main roles is qualifying TIM materials and understanding whether that particular sample will actually work in a given application. Heat flow or heat flux is one of those.

Another factor is the size of the chip itself. Larger die sizes will result in more warpage. There is a CTE mismatch, or a coefficient of thermal expansion mismatch, just being a property of the material between that silicon wafer and the lid, which means that your TIM 1 material is going to experience the stress and the strain of any kind of flexing or mismatch between those as the temperature changes, maybe through power cycling or temperature cycling. A larger-size chip, particularly the corners and the edges, is going to experience longer stress and strain, so you might need to choose, for example, a TIM 1 material that has a softer, maybe lower modulus, to be able to accommodate and move with that without actually delaminating from either the wafer or the lid. In addition, you might want a TIM that has more adhesive properties that’s going to adhere better to the chip to accommodate that, so die size in addition to heat flow is part of that. The last one I’m thinking off the top of my head is the temperature: What are the extremes that this particular material is going to experience, both on the cold side and the hot side, and this will depend on the application. So generally speaking, for reliability testing to qualify a TIM material in a consumer electronics application, you’re going to need to pass reliability thermal cycling that will go from -40°C up to about 125°C. If it is a chip that is not going into a consumer electronics, but rather into maybe an automotive application – “computers on wheels,” as they’re essentially becoming – those chips now have to cycle from -40°C, and sometimes even lower than that, up to 150°C. So rather than 125°C on the high end, now it needs to go to 150°C. And as it happens, with certain types of materials, that variation between 125°C and 150°C makes things change in the polymer on a molecular level that could adjust or change the modulus or the adhesive properties.

There’s a lot of clever chemists at DuPont and Laird who work to develop formulations that can go from 125°C to 150°C without maybe experiencing those changes. That’s certainly a challenge in the industry now: Understanding the temperature extremes and how any given material is responding and its modulus and its adhesive properties, and then of course, its thermal properties.

MB: When we’re talking about those temperatures, my understanding is that the TIM 1s are mostly silicon-based, correct?

CW: The ones offered by DuPont are currently silicon-based TIM materials, and that means that they’re dispensed in an uncured state and then they go through the curing cycle once they’re in the package. That will help to cross-link the material, to make sure it’s going to be adhering better on either end. Also, it slightly increases the modulus just to make it less “flowy” and stay in place nicely during those reliability tests.

MB: Let’s talk a little bit about the processing. Are they always dispensed, or could you apply these to the board or in general through any other mean?

CW: Generally speaking, the silicon-based materials that go through here are dispensed onto the chip either in a pattern of some sort and then the lid is pressed on, and that’s an automated process. The types of dispensers vary a little bit depending on the material or depending on the OEM manufacturing it. There are a couple of exceptions, ones that I’m maybe slightly less familiar with because they come from other companies, but there’s some solder pad materials that would be solid in room temperature states. We place them in a solid-state and then burn it in or melt in, and that will melt into place, but those are for very niche applications and sometimes don’t meet the same kinds of reliability requirements that polymer TIM applications are used for.

MB: And this might be diving a little bit too far into the weeds, but is the nature of these materials thixotropic or pseudoplastic?

CW: You’re talking to a mechanical engineer here, not a chemist. [Laughs] I honestly don’t know the answer to that. I know that there are people that DuPont that would, but being someone who works more on the application side rather than the formulation side, I can tell you that in their uncured state, when I have run tests with them, they’re gooey, kind of like melted cheese, and stretchy, very good adhesion. And then once they go through the curing process, we like to refer to them as more of a gel material. They have a little more springiness, a little more elasticity.

MB: OK, so this might be more up your alley. In your experience who makes the call on TIM use? Are they designed in, or are they added afterwards because testing is showing that there’s unacceptable thermal gradients or some other heat problem?

CW: Oh, it varies so widely. I’ve been working specifically in this TIM area for about five years, after doing a lot of academic research in this space. And when I first joined [DuPont] five years ago, most of it was kind of what you described. Later in development stage where they’re like, “Oh my goodness! The electronics engineers have designed this thing that’s producing a ton of heat. And now we have to respond and try to find a thermal interface material that will meet whatever scenario has been thrown at us.” Some of the higher-end electronic device manufacturers are starting to incorporate thermal management earlier in the design phase, which in my opinion is fantastic because it means, rather than having someone come at you and say, “Here’s our PCB, and here’s the spacing of all our components, deal with the thermal,” you can come back and say, “Well, gosh, it would be really great if we could separate out the memory and GPU just a little bit more so that we can have a more even distribution of heat. Or maybe we’ll incorporate some heat spreaders or something like that.” And there can be more of a conversation back and forth. Designing, scaling up and manufacturing PCBs is expensive and it takes a lot of effort to figure out the placement of everything. If you don’t consider the thermal, oftentimes, by the time thermal is incorporated, you’ve already got a design, you’ve already done scale up, you put in all of that early funding. You don’t really want to go back and start from ground zero moving things around. The earlier the better. It varies so much. We work with a lot of different customers and I think many of them have their own approach to it.

MB: Are you seeing TIMs used as a possible replacement for heat sinks, or are they typically going to be used simply because there’s no other solution, but the heat sink is still going to be there to resolve some subsequent issues?

CW: The thermal interface material doesn’t act as a heat sink. It’s merely the means to get heat from one place to another. If you were to literally stick the heat sink, which is usually metal, directly on top of the lid, you’re going to have metal on metal and, on a micro scale, that has a lot of air gaps. Air is a thermal insulator. You don’t want that. So really the TIM is just serving to fill all those little crevices. So no, I don’t see the heat sink going away. However, what exactly the heat sink is varies a lot. Historically you would see finned heat sinks, just metal fins. Sometimes you see pin fins, which are more like individual rods sticking up, and you have air flow. So for any mechanical engineers [reading this], those heat transfer classes, conduction cooling, just got air flowing over it. And the different kind of controls that we can address with that or the temperature of the air, the speed of the air. And that’s about it. And it takes a lot more HVAC cooling if you need to lower the temperature of the air, or if you need to turn the fans higher to blow the air faster, that takes energy.

And it’s also loud. I don’t know how recently you walked through a data center, but oh my goodness, when fans are running at 100% duty cycles or 80% duty cycles it is loud. Ideally you want to try to reduce that as much as possible. And people have designed all sorts of cool, cute things to do this. Now we start seeing heat sinks that have heat pipes incorporated inside of them. It’s usually copper, kind of vertical heat pipes, and horizontal fins. You still have air blowing over it, but the heat pipes introduce an evaporative cooling component which is pretty nifty. Then you have both convection cooling and evaporative cooling happening inside the heat pipe. But in essence you’re still just blowing air over it. When we get to a really high end, especially in data center applications, we’re starting to see liquid cooling. You might have a cold plate with an inlet and an outlet for liquid coming in and even in many of those cases, you still need to have thermal interface material because that block of metal that is the cold plate has to attach somehow to your lid, or in some cases to the die itself. Some designs will actually remove the lid and in that case we call the thermal interface material TIM 1.5, kind of a hybrid. Essentially, you’ve got the backside of the die, the TIM 1.5, and then some sort of heat sink sitting on top. But in any case, the heat sink can come in many, many forms. I probably haven’t even talked about half of them but it’s a great place for a designer to get creative and also think really critically about the space you have to operate with.

MB: For companies that are really thinking this through, who all is in the room at the outset?

CW: It’s going to be a really great cross-section of engineers: electrical, mechanical. You would probably have PCB designers in there. Probably have some budget people thinking about how much things are going to cost. You might even have some general designers as we know working in the electronics industry, everything gets ripped apart on iFixit or one of these online websites. So you want to make it look pretty from the inside. So yeah, honestly, those that would be my guess off the top of my head since as a supplier of raw materials I’m never sitting in that room. But that would be my guess. Folks in there are going to range from electrical to mechanical and design.

MB: Let’s switch gears for a moment. You’ve been involved in the Society of Women Engineers since your undergrad days and continued that effort while working on your doctorate. What drove you to get involved?

CW: When I started my undergrad at Santa Clara University, I was in a class of mechanical engineers, about 90 of us, and I think there were maybe six, possibly seven mechanical engineers who were women. In high school I never really thought too much about the breakdown of gender because most classes were split 50:50. But I’ll tell you, it’s pretty shocking to walk into one of your morning seminar classes and be one of two women in a 100-person class. And it really hit me in a way that I didn’t expect. And I did actively seek out ways to engage with other women that were sort of going through the same process as me, a little bit solidarity, a little bit social, and also really working to make sure that future generations were not going to experience that same thing that I had just being sort of one of the lone wolves in the room. Society of Women Engineers is an international organization. They have sections that are at the collegiate level. They have sections that are professional sections. I’m now part of the Santa Clara Valley section of the Society of Women Engineers on a professional level. But the undergrad sections just do a fantastic job of engaging and creating a space for young women who are desiring to pursue engineering, to really share their joys and their struggles, but also to connect with professionals in the area that have gone through that and seen the other side of it. I think it’s a fantastic organization I’ve been involved in. Like you said, ever since undergrad and continuing through grad school and now, as a professional member.

MB: Per the National Science Foundation, if we look at all science and engineering degrees, women accounted for half of them in 2018. But if we look a little closer, the NSF goes on to note just 22% of engineering degrees in 2018 were awarded to women, which is up only four points in 20 years. Now, the percentage of doctoral degrees has almost doubled in that time. Women aren’t just switching to coding either. I want to point out that percentage has actually declined seven points in 20 years. I’m going to guess that awareness and recruitment were really big topics of conversations in some of your SWE chapter meetings.

CW: Huge, huge, Mike. Absolutely. So the studies done by Society of Women Engineers, NSF and then I believe the American Association of University Women (AAUW) have shown that women and young girls typically start self-selecting out of STEM classes whenever they can, where they start telling themselves that “I’m bad at it” and that kind of perpetuates the desire not to pursue it, between 5th and 7th grade. And if someone starts telling you at that age, “Well, you’re just not good at it,” then you’re not going to have a desire to do it. And when I read that data, I thought back to my 4th grade teacher who told me the opposite. He told me “You’re good at math,” and had me start doing some advanced stuff with a couple other students. I’m sure at the time I didn’t think too much of it, but for all I know that has been the linchpin that got me excited about it and continuing.

For outreach efforts, that’s a big part of SWE, where we have SWE Next, which is sort of like an elementary to high school club to try to engage even younger students as much as possible, we would do a lot of outreach activities trying to bring hands-on engineering to students at young schools and again, not just women. We’ll bring these activities to classrooms that are of all genders, so that’s the part of it, but one of the things I really want to highlight is something that often gets overlooked. Many times, when people say, “What are the key skills that you need to be an engineer?” [the response is], “Oh, you need to be good at math and science.” But the conversation ends after that. So you could imagine a young girl hearing that thinking, “Well gosh, I don’t like my math and science classes,” or “I’m not good at it,” and they’ll just figure out I won’t be a good engineer. What I like to say to that is, “If you’re an engineer that’s really, really good at math and science but you have no creativity whatsoever, you’re not a good engineer.” You could be so good at these, but we really need people who are thinking outside the box, thinking creatively, and part of thinking outside the box is having people from different backgrounds who just naturally think differently because they’ve experienced different things in their life, and that could be gender, it could also be cultural, it could be socioeconomic status … there’s so many different things. I had a design engineer tell me when I was an undergrad that when they were originally setting the building code standards for kitchens, they set the countertop height to be appropriate for the average male, because all the people sitting on the standards board were men. But at that time most of the people that cooked in the kitchen every day were women. And so they spent all this time and money, and they built all these standards and they started doing testing, they brought women in, and the woman said, “These counters are way too high!” I think that’s a very funny kind of practical example. But you know the reality is, is that most of the things that engineers design and build are being used by men and women. And so if we don’t have a diversity of people sitting at the table we will end up with a counter that’s too tall, metaphorically speaking. I really do feel strongly about getting that pipeline going and trying to remind young girls that creativity is as much a part of it, if not more so. than just being good at math and science. I did not like physics when I was in high school, and I became a mechanical engineer, so what do you know!

MB: I totally get the creativity part. We had a panelist at our PCB West conference last year who is the director of engineering for Collins Aerospace. She talked about how kids who play Minecraft think in 3-D, they think in abstract ways. And she felt that the next generation of engineers, or rather the folks who want to find those people, should be focused dead center on that group of kids because their brains are already wired that way.

CW: Yep.

MB: Are there specific things along those lines that we in the industry can do to help encourage this and to help, not just young people – because I agree with you, it’s got to start in elementary school – and not just educate them as to what the possibilities are, but then also help them walk through a path so that they could see where the things that they’re doing today might actually translate into the really cool products of tomorrow?

CW: Oh boy, that’s a great question. What are the things that we can do? It really comes down to how are we educating young minds. I don’t have children myself, so I’m not really as familiar with what the school system looks like if I were to hop into a classroom right now. But I hear a lot about teaching to the tests and having a lot of these kind of closed-formed questions where there is only one answer. I think that if we want people to start thinking outside the box and being more creative in their approach, we need to give them challenges that have more than one solution. Almost all the activities that Society of Women Engineers brings into the classroom are these sort of open book options. We give you a bunch of tools and we tell you, “This is the goal that you’re trying to shoot for, but however you want to do it, go ahead and do it.” The simplest thing was one where we give a bunch of paper and tape and twist ties and a few other things that everyone has exactly the same amount of it, and a marble. We say, “You have to start at table height and design some sort of something” – we don’t have to call it a ramp, although most of them end up doing a ramp of some sort – “that will allow this marble to travel to the ground as slowly as possible, and whoever’s marble takes the longest to get from top to bottom is the winner.” And people will do spirals, kind of the swirly slide of some sort or different things, but once in a while we get a kid who designs a full lever system. It’s like, “Wow! You were not taking the easy route.” They didn’t look at what other people around them were doing. I just get so excited when I see that and, to me, that maybe those are the kids doing Minecraft, essentially because Minecraft is a giant open-source game where you get to do whatever you want to reach your goal. That’s exactly the kind of stuff that we can and should be doing more of in schools.

MB: What are some of the things that DuPont is doing to help move the needle in terms of attracting more women to engineering in general and perhaps specifically to electronics?

CW: I think there’s some practical things from the benefit side, and this is not just DuPont, but DuPont is on the corporate board for SWE, so certainly they help playing their role in any kind of lobbying efforts or different logistical things that SWE is trying to do on a more national level. But as a company, I would say some of the big recruitment tools and again, bearing in mind they’re usually recruiting people in their 20s and 30s who are coming out of undergrad or Ph.D. programs, they recently increased their paternity and maternity leave. So if you’re someone who’s looking for a company and thinking of starting a family, that’s kind of a big deal. Not all companies have really generous policies. Or more importantly, they have a policy that people might not use it or the culture doesn’t encourage people to use it. And I have absolutely seen both men and women taking full advantage of that at DuPont. I see that as a really positive thing, because it creates a culture of welcomeness and inclusivity and when people then come back from maternity or paternity leave, I’ve seen people get promotions a couple weeks afterwards. There isn’t a negative downside to that, and I think that is a cultural thing that probably takes years to build. DuPont, I believe, has done a really excellent job of that. We have an internal DuPont women’s network, or a DWN, and we bring in external speakers as well as internal speakers talking about different topics that are relevant to women. So that could be, how we can bring our whole selves to the workplace, or create a culture where we don’t feel like we need to hide a certain part of our personality or background when we come to the workplace? That might sound really foreign to some, but I was really surprised there’s certain factors of people’s culture or personality or whatever they just never share. And then because of that, they feel like they’re hiding something, and that can ultimately be detrimental to their presence in the workplace. One thing we really try to be more open about is talking about wage equality and fighting for promotions and knowing how to promote yourself, how to speak up in a room which oftentimes can be very male-dominated. We create spaces to have those conversations. DuPont’s Woman Network is one of those. Beyond internal workplace organizations, we have been doing work for recruiting externally to try to increase our physical recruitment pool of women engineers. That includes recruiting at the National Conference for Society of Women Engineers. It includes reaching out not just to Society of Women Engineers, but any kind of other chemistry, women organizations or clubs or campuses, when we do campus recruiting, to make sure that those clubs are advertising to their constituents to come out when we recruit. There’s a couple different avenues we are going. Those are the ones I’m taking off the top of my head, but it’s certainly something that is in our thought process as we go through recruitment.

MB: And how would someone in industry get involved in Society of Women Engineers?

CW: You can go on to the Society of Women Engineers website (www.swe.org) and search for a section near you. If you live near a big city, odds are there probably is a big section. If you live more rural then you might have to join virtually. We’re kind of all slowly transitioning out of the Covid era and maybe just beginning to offer some more in-person events. My local section has been doing coffee hours roughly once a month where they choose a local coffee shop and have a range of a couple hours one morning and people can come out and grab a cup of coffee and chat, and that has surprisingly been a really successful avenue to get people connected. That would be my first thing; just start seeking out a local group and go to an event, get involved, meet people and you’ll be really surprised. Everyone’s so friendly and so eager to help out. I work in the Bay Area and we’ve had some layoffs from various tech companies in the area, so there’s been some women in our section who are now seeking new jobs. We’re having these wonderful conversations about, “How do I update my resume for the first time in five to 10 years?” and “Making sure that I’m getting the salary I’m worth, and how do I negotiate that?” These are all extremely valuable conversations, some of which might be considered taboo in certain circles, but we’re trying to break that down and really be transparent about it among the women in the group. I think these sections are great. I encourage any women or for that matter, men who are allies and interested in, especially ones who might be responsible for hiring and trying to figure out well, “I put out this job offer and the only people that applied are men. What do I do?” Join SWE. Talk to some of us. We’ve got lots of different suggestions to help folks that are trying to diversify their hiring pool.

MIKE BUETOW is president of PCEA (pcea.net); mike@pcea.net.