Mind Your Units

Buyers beware: An ounce of copper is not 1 mil.

Long before I became part of the PCB industry some 30 years ago, a large study determined that for the typical two-layer printed circuit board, the amount of copper required for a reliable connection in a plated through-hole (PTH) was 0.0007 inches, or 0.7 mils.

Anything less than that could compromise PTH reliability, the study found, and anything more would not make much difference.

Simply put, the 0.001″, or 1 mil, as stated on most PCB fabrication drawings is a safety factor. Some corporate fab specs will even state a plating average of 1 mil, with 0.8 mils as the minimum, higher than the originally determined 0.7 mils.

However, even today, some PCB buyers confuse ounces with mils when it comes to the copper plating of a printed circuit board. It is important to know the difference.

The copper weight called out in a PCB is rated in ounces, which is the amount (weight) of the copper covering 1 sq. ft. of bare fiberglass material. In inches, 1 oz. of copper equates to a thickness of 1.34 mils of copper on the PCB – not 1 mil – and that is where the confusion lies.

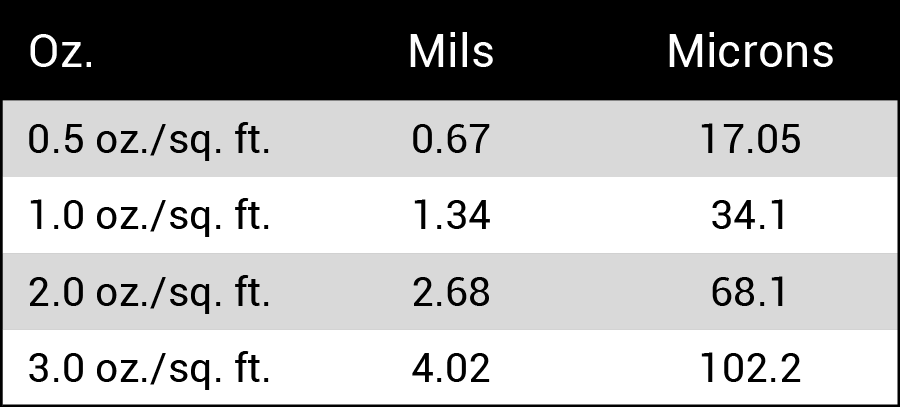

When referring to “thickness,” we are really talking about the weight of copper used in the PCB. Table 1 shows a helpful conversion chart between copper thickness values in weight, mils and microns.

The plating of a circuit board is a subtractive and additive process. Unless otherwise specified, the typical plating process most board manufacturers provide is around 1 mil of additional copper plating on top of the existing (or start) material.

PCB buyers must understand the manufacturing process to ensure they meet their customers’ true copper weight requirements because the amount of copper plated on the surface means there might not be as much copper in the hole.

Copper is expensive, so to save money on a board that requires a 2 oz. finish, buyers will sometimes mistakenly ask the PCB vendor to “begin with one ounce and plate up to two,” thinking that mil of plating is just enough to meet their needs.

Unfortunately, it is quite a bit less than required. Two ounces of copper equates to approximately 2.7 mils, and what the buyer just asked of the supplier will yield a PCB that has, at most, 2.4 mils of copper (1.34 mils to start plus the 1 mil plated). That’s 10-15% less copper than desired.

Would that difference in thickness cause a problem for a PCB buyer’s customer? I can’t make that call. But by asking the board manufacturer to begin with 1 oz., the buyer is not getting what was asked for in the fab drawing.

The above computation does not permit the tolerances of the raw material itself. The copper on the clad material received may be on the lighter side, and that will affect overall finished thickness as well.

I don’t mean to put all the blame on buyers. Many PCB salespeople confuse mils with ounces. To make their pricing more attractive, they too will offer to begin with 1 oz. and “plate up” to two. But a knowledgeable salesperson should find out the “start” weight up front.

Specifying on your PCB fab specs the copper start or “finished” weight of the designed circuit board is crucial for design or price.

If design, it is best to put what raw material you want your design to begin with, knowing that an additional 1 mil of copper will be applied during the normal manufacturing process.

If cost, then specifying the finished weight gives the board manufacturer the option on what weight to start with, as the amount of copper the raw material requires will dictate the final cost of the PCB.

The most commonly called-out copper weight value is 1 oz. finished, meaning the copper weight will be at least one ounce once completed, whether the PCB manufacturer starts with 0.5 oz. or 1 oz. of raw material that was plated to a higher value.

There is usually no extra charge when 1 oz. finished is called out. For weights above 1 oz., there will be additional cost and lead time for material availability.

PCBs that require heavy copper weight also incur additional process time for etching (the removal of all that extra copper) and to ensure customer-desired trace width and spacing is maintained.

And don’t forget about PCB freight costs. Heavy copper means more weight, and thus more in shipping costs and proper packaging to hold those heavy boards in place during transit.

Mixing up ounces and mils can be a costly mistake, both in dollar terms and in maintaining a relationship of trust between PCB buyers and their customers. Don’t overlook the details when it comes to the copper plating of a printed circuit board.

Greg Papandrew has more than 25 years’ experience selling PCBs directly for various fabricators and as founder of a leading distributor. He is cofounder of DirectPCB and can be reached at greg@directpcb.com.