Good Signs: IPC Apex Booth Traffic Suggests Busy Year Ahead

Exhibitors hope new products will keep the order books filled in 2023.

The good times of 2022 carried over into January as the industry turned out for one of the larger IPC Apex Expo trade shows in some time. The San Diego Convention Center show floor was humming for the better part of the first two days of the three-day event, and most of the more than 300 exhibitors seemed pleased with the attendance.

Most companies, in particular the assembly equipment suppliers, reported strong bookings for the quarter. Several added that they’ve raised their full-year forecasts as result of the surge.

A few years ago, there was a big push toward the connected factory. The branding and implementation of the machine-to-machine standard known as Connected Factory Exchange, or IPC-CFX, is now so ubiquitous, it was only sporadically mentioned throughout the week.

Noting data mining issues with PLCs, Aegis showed PLC Gateway, a web server that opens connections to PLCs, displays CFX message types and maps the two. The platform-independent system acts as an edge server and works with “anything that uses CFX,” said Jason Spera, CEO.

AIM’s newest zero-halogen solder paste features improved electrochemical reliability, powerful wetting and exceptional fine-feature printing. The material is designed for automotive, LED and aerospace assemblies.

ASMPT’s DEK TQ L stencil printer will be the company’s primary platform going forward, ASMPT’s Mark Odgen said, noting an entire shift can run on a single solvent tank and one roll of paper. The company also revealed Virtual Assist, an AI-based training tool (it learns and responds to user questions) that operates via an Android/IOS app or a browser, is adaptive and collects practical experience from the service staff throughout the whole enterprise.

ECD showed its latest M.O.L.E. thermal profiler, the EV6. A “traveling” device, it operates via a capacitive touchscreen, which allows configurations to be set up on the display, eliminating the need for a computer to conduct oven analysis. It is backwards-compatible with the legacy Rider system.

Europlacer showed its Stock Management tool which monitors and controls the supply of components to the assembly line in real time. The system is intended to reduce the time it takes to locate and replenish components on the placement machine.

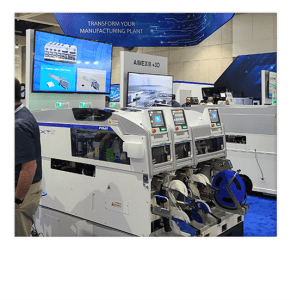

Fuji’s AIMEXR placement platform is designed to handle larger panels such as server boards. The machine can be outfitted with two custom heads and has additional feeder slots.

Glenbrook Technologies has a new dual x-ray image processor called the GTI-5000 that switches the field of view from 25 microns to 82mm and can show the entire part and an individual wire with a single touch of a button.

Juki’s new LX-8 placement machine has a 20-nozzle head and is capable of up to 105,000cph (company rated). The 8-nozzle Takumi head can be changed on the fly, and the 160-feeder capacity allows exceptionally long runs.

Mirtec has installed a new GUI that is 25% faster than the previous version used on its inspection machines. It enhanced the image quality on the MV-3 Omni 3-D AOI, and added a PCB flipper for its inline machines.

Mycronic’s inspection systems took a step forward with new head technology known as IRIS for its 2-D and 3-D AOI. The system features higher resolution and is 30% faster. The new MyWizard software has an escape tracker that automatically updates the user’s library based on what the operator diagnoses is a false call or a true defect.

nScrypt showed an eye-opening range of precision dispensing products, from solder to printed antennas to curved resistors, done on a wide variety of substrates. Its SmartPump can also print active devices, including bare die, the company said.

PVA noted its Ultrafine spray valve, with a 2mm width that can get close to keepout areas.

Saki’s 3Xi-M110 V3 AXI reports cycle times that are twice as fast as the machine previously could do. Its combination of planar CT for solder joint defect detection and Real 3D volumetric inspection to spot voids and head-in-pillow issues uses 40% less power per board than the older models.

Yamaha featured the YRM20DL SMT placement machine, with a high-rigidity dual-lane conveyor said to improve productivity and be capable of handling PCBs up to 330mm in width, and PCB lengths of up to 380mm in parallel mounting mode. The placement speed is 120,000cph with an accuracy of ±15µm (Cpk≥1.0).

Zestron revealed its latest cleaning technology, the X728, a pH-neutral defluxing agent.

New Exhibitors

New to the show was DarwinAI, a Toronto-based OEM of solder inspection equipment. The three models of its VQI AOI range from mobile (capable of inspecting boards up to 13 x 17″) to inline versions (24 x 24″, max.). The top feature is its fast programming time, which in demos took less than one minute.

One of the more interesting developments we saw was from Loveland, CO-based X2F, which supplies molding equipment for protecting electronics from heat. Using third-party materials, the system offers an alternative to potting and conformal coating by overmolding even the most viscous materials. Three platforms are available, ranging from low to high volume capacity.

Fab Developments

The fabrication side of Apex was much smaller than the assembly segment. New printed circuit board processing equipment is hard to find at the show; many of the machines on display were first seen at Productronica in 2019 or 2021, and won’t be mentioned here.

Isola emphasized its Terragreen 400G low-loss laminate and prepreg. The halogen-free material is easy to handle and has a Tg of 210°C, Td of 400°C, and a Dk of 3.5.

Ucamco showed Jayda, a website-based workflow engine tool that exposes basic characteristics of a company’s data set – e.g., the board type, number of layers, line widths and spaces, etc. – and performs online quoting.

Ventec showed a host of laminates designed for RF/microwave applications. The tec-speed 30.0 RF PTFE material features a thermal conductivity of 1.15W/mK, for superior thermal performance in high-temperature applications, and a low Dk of 3.5, good insulation resistance and high dimensional stability. The new tec-speed 20.0 (VTM-1000i) is a hydrocarbon laminate, said to offer excellent thermal reliability and Dk of 9.8 and Df of 0.0023. The redesigned tec-speed 6.0 (VT-462SH NF/LF) is an ultra-low-loss low-flow/no-flow environmentally friendly material for drones and UAVs.

All-in-all, a good way to start the year.

Mike Buetow is president of PCEA (pcea.net); mike@pcea.net.