ESD Protection and Packaging/Unpackaging

A DoE reveals the packaging type matters less than the process used.

The need for electrostatic discharge (ESD) protection is drilled into production workers from day one in most electronics manufacturing facilities. Most facilities have multiple layers of protection including floor tiles or conductive coating, smocks, individual grounding devices, ESD mats on workstations, and ionizing blowers throughout the production process. There are also multiple layers of protection from conductive totes to metalized bags for product as it ships out. There is a tendency to believe more protection is always better. Given that the seven wastes include both defects and overprocessing, however, from a Lean manufacturing standpoint there is value in analyzing how much protection is required for shipped products. Considering whether multiple layers of protection create a false sense of security with operators involved in pack/unpack operations also has value.

The team at SigmaTron’s facility in Chihuahua, Mexico, recently studied what types of packaging and processes provide the most value in terms of ESD protection during the pack/unpack process. The primary goal was to understand if packaging or processing deficiencies were creating defect opportunities in either the packing process at the EMS facility or the unpack process at an OEM’s facility, and implement appropriate corrective action. A secondary goal was to utilize the design of experiments (DoE) data to optimize packaging decisions so that products were appropriately protected by the right level of ESD protection.

The team started by designing a packaging DoE to analyze protection provided by cardboard, conductive cardboard and antistatic bags for products during packaging, in transit and unpacking.

Four different products and associated packaging were tested:

- Product A is a printed circuit board assembly (PCBA) in a plastic housing packed in a regular cardboard container

- Product B is a PCBA in a plastic housing inserted in an antistatic bag and then in a regular cardboard container

- Product C is a PCBA packed in black conductive ESD cardboard with dividers

- Product D is a PCBA packed in black conductive ESD cardboard with a tray.

A Model 8154 ESD Field Meter providing readings in kilovolts (KV) and a Megger Model PRS-801 impedance meter providing readings in ohms were used under an ASTM D257 measurement methodology.

Samples were measured under three different conditions in a work area that included an ionized air blower:

- Samples were measured before packaging at the final inspection table under ionized air, using the field meter to confirm existence of electrostatic charges. These measurements were made on two locations on the sample

- Samples were measured again inside the box prior to closing the lids

- Boxes were handled for 10 min. and then the measurements were repeated.

Gage R&R studies were conducted and a measurement systems evaluation (MSE) ranges chart and averages chart were developed to establish statistical process control (SPC) limits.

The results of the tests showed:

- Adding ionizer blowers helped to reduce or eliminate electrostatic charges when opening boxes in all scenarios

- Antistatic bags did not make a difference on the charges measured for Product B

- Black conductive ESD cardboard did not show a significant difference on charge generation for product C

- Handling material in trays through the process maintained close to zero electrostatic charges in Product D

- Use of shielded bags and correct location of ionizers kept charges at zero.

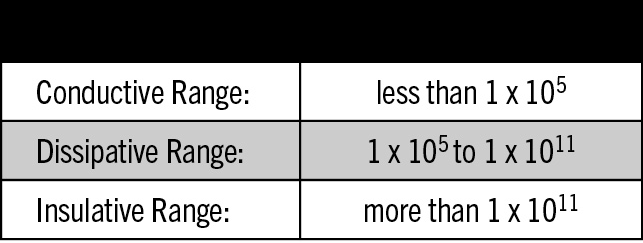

A test of regular cardboard for conductivity found the material to be dissipative. TABLE 1 shows the results.

The most significant conclusion was that correct positioning of ionizer blowers and the operator’s correct use of trays and grounding devices had the most impact on minimizing or eliminating charges. This underscores the need for pack/unpack operators to be well trained in following procedures related to ESD workspace compliance, regardless of the packaging used. Conductive cardboard and antistatic bags did not perform significantly better than regular cardboard.

Based on the study’s data, the OEM determined that the packaging choices made for specific products provided acceptable levels of protection and that more focus needed to be placed on positioning of ionizing blowers in the unpacking operation.

While the study is not being used to suggest that OEMs eliminate the levels of packaging they have specified for their products, it is being used to provide OEMs considering a packaging change with an assessment of the effectiveness of different types of packaging under controlled conditions. Given that different classes of components have different levels of sensitivity to ESD, all packaging options should be considered. That said, this study enables OEMs to do a more detailed cost/benefit analysis when considering which levels of protection make best sense for their products.

Alvaro Gardo is manufacturing engineering and quality manager at SigmaTron International (sigmatronintl.com) in Chihuahua, Mexico; alvaro.gardo@sigmatronintl.com.