Surviving the Rush to Tape Out the Printed Circuit Board

Design constraints often morph with lessons learned from the prototype.

Can we just assume that every board design is going to be a nonlinear effort? While we know that everything is subject to change except the tape-out date, there are a few ways we can taxi toward the runway of product launch.

Today’s supply chain is tighter than the one in the textbooks on product management. The printed circuit boards are often in the critical path, whether they are test jigs for prototypes or the final mass-production units. A schedule slip on P1 cascades to P2 and everything gets compressed. Execution is essential. Otherwise, we won’t have time to learn the lessons of the first iteration before committing to the next.

This creates a dynamic where there are likely to be updates to the schematic at different points in the layout cycle. When we’re designing something that is new from the ground up, we make educated guesses and assumptions about almost everything. Chips don’t lie and can’t fix themselves after a layout that doesn’t “let them eat.”

Keep ‘everyone’ in the loop for drastic revisions. Fundamental lessons learned on the initial design are inevitable. Thus, the designer must be able to create a second revision where it doesn’t appear to have bug-fixes slapped on top of the first try. An example of this is when an analog circuit needs to have a series element added.

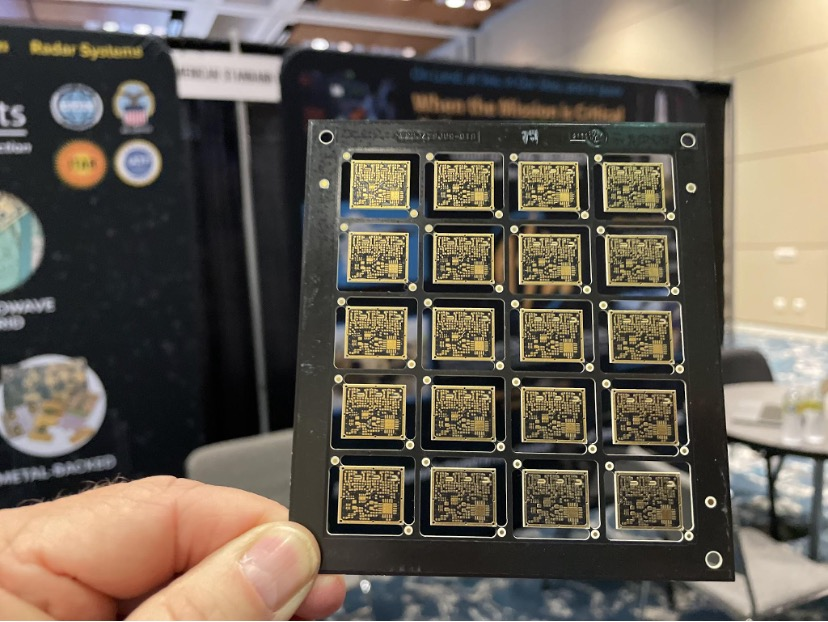

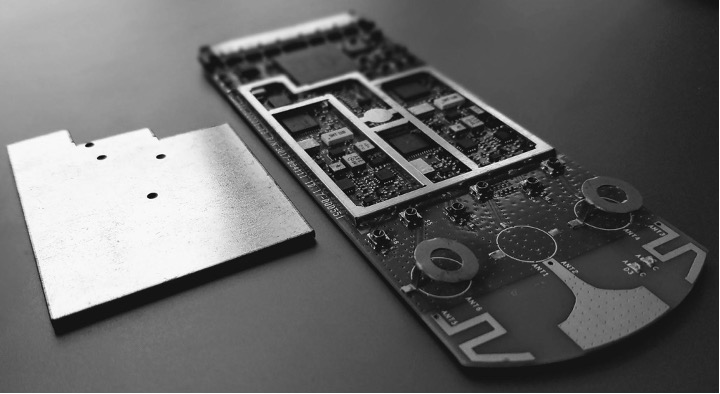

The first version used a placement that had the absolute minimum length of RF routing. The whole chain is made up of parts at minimum spacing. This is what you should do every time, so that’s what ended up happening the first time. Forget that old board and redo as much of the placement as it takes to have impeccable transmission lines again. When you’re done, it will look like it was always meant to be that way. It may happen again. Scratch that. It will happen again. You just have to cycle through it enough times that you’re not surprised at the design review.

Doing your best work and being willing to rip it right up for something better is the hallmark of a good design service. Taking pride in your work and being able to disown it later will help you cope. The “pointless” effort opened the door for the improvement to come. I have found that changes are easier to take if you frame them as improvements. As a team, we go from guessing what will work to learning what will and implementing that hard earned knowledge.

Widen the road between MCAD and ECAD tools. Improvements are inevitable and provide a never ending source of work. When times are slow, there will be a chance to look at the component library for anything that should be improved. It is common for the mechanical data concerning connectors to conflict with the footprint. Working from a step model, the mechanical engineer uses the nominal values for length, width and height.

Librarians may have tried to help by using maximum height values or adding a courtyard that exceeds the specific zone created for that connector by the product designer. This is a case where building in a safety margin is working against the designer. A part placed in accordance with the mechanical engineer’s intent should not cause design rule violations. It’s a good use of spare cycles to strengthen the synapses between mechanical and electrical design.

One of my mistakes is to think I will have time to clean up the reference designators for the silkscreen and assembly drawings. Now, I try to consider the non-metal layers earlier so that only the new parts have wonky text at tape-out time. When you revisit these layers toward the end, the oversized, mislocated strings of text reveal the churn that happened along the way. That’s reason enough to try to get ahead on this task. Look at all those improvements!

It’s not just arranging text. The design constraints often morph a bit with the lessons learned from the original prototype. Fix the board by fixing the rules, and then following them. It will take longer the first time encountering a request for a specific line width/length. Having that information embedded with the layout will help with design verification and make it more repeatable after ripping up the previous incarnation.

Do a tape-out just to see what happens. A dry run of the tape-out will reveal any showstoppers lurking in the design. Shapes can be corrupt from the beginning but only manifest when it’s go-time. Making sure the part numbers and descriptions are all in alignment with the next revision will help.

As always, fab and assembly vendors play a key role in the PCB launch. Getting them onboard for the next wave is so important. No fun when you meet your part of the schedule but the vendor doesn’t have a DfM slot or even material for your project. If no one else is managing that, then you should get out in front of that effort.

If failure is not an option, I would engage two (or more) vendors for the fabrication and let them have an undeclared race. The minimum order quantity and tooling charges could make that unfeasible, in which case the choice of vendors becomes very important. If you’re bound to use a single source, know their capabilities and limitations. While dealing with one vendor is easier, the risk of schedule slip is higher. Spreading that risk is my key piece of advice on managing the supply chain these days.

In summary, it pays to improve your editing skills and to dabble in project management where necessary to have things in control as the board goes to fabrication. Digesting the lessons learned and getting as close as possible to a ready-to-go board file ahead of the last-minute rush will allow you to sleep better. You need your rest in that final push. Getting a solid inter-group process down will make life easier. Soften the barriers and remove the impediments that drag out the process by being an advocate for your own cause. ![]()

John Burkhert Jr. is a career PCB designer experienced in military, telecom, consumer hardware and, lately, the automotive industry. Originally, he was an RF specialist but is compelled to flip the bit now and then to fill the need for high-speed digital design. He enjoys playing bass and racing bikes when he’s not writing about or performing PCB layout. His column is produced by Cadence Design Systems and runs monthly.