August 2024

This issue of PCD&F / CA brought to you by:

and NEIL HUBBLE

PCEA

PO BOX 807

AMESBURY, MA 01913

PCEA BOARD OF DIRECTORS

Stephen Chavez, CHAIRMAN

Justin Fleming, SECRETARY

Gary Ferrari, CHAIRMAN EMERITUS

MEMBERS

Jim Barnes

Michael Buetow

Tomas Chester

Douglas Dixon

Richard Hartley

Matthew Leary

Scott McCurdy

Anaya Vardya

Susy Webb

Eriko Yamato

pcea.net

PUBLICATION

- PCD&F/Circuits Assembly digital.pcea.net

WEBSITES

- PCD&F pcdandf.com

- Circuits Assembly circuitsassembly.com

NEWSLETTER

- PCB Update pcbupdate.com

PODCASTS

- PCB Chat pcbchat.com

EVENTS

- PCB West pcbwest.com

- PCB East pcbeast.com

EDUCATION

- PCB2Day pcb2day.com

- PCEA Training pceatraining.net

- Printed Circuit University printedcircuituniversity.com

AWARDS PROGRAMS

- Service Excellence Awards circuitsassembly.com

- NPI Awards circuitsassembly.com

pcdandf.com

DATABASE

- Directory of EMS Companies circuitsassembly.com

mike@pcea.net

frances@pcea.net

Peter Bigelow, Robert Boguski, John D. Borneman, John Burkhert, Jr., Stephen Chavez, Geoffrey Hazelett, Mark Finstad, Jake Kulp, Nick Koop, Alun Morgan, Susan Mucha, Greg Papandrew, Chrys Shea, Jan Vardaman, Gene Weiner

production@pcea.net

nathan@pcea.net

frances@pcea.net

will@pcea.net

frances@pcea.net

mike@pcea.net

jacqueline@pcea.net

PRINTED CIRCUIT DESIGN & FAB/CIRCUITS ASSEMBLY is distributed without charge to qualified subscribers. To subscribe, visit pcdandf.com or circuitsassembly.com and click on Subscribe.

For changes or cancellations to existing subscriptions: subscriptions@pcea.net

PRINTED CIRCUIT DESIGN & FAB/CIRCUITS ASSEMBLY is published monthly by Printed Circuit Engineering Association, Inc., PO Box 807 Amesbury, MA 01913. ISSN 1939-5442. GST 124513185/ Agreement #1419617.

© 2024, by Printed Circuit Engineering Association, Inc. All rights reserved. Reproduction of material appearing in PRINTED CIRCUIT DESIGN & FAB/CIRCUITS ASSEMBLY is forbidden without written permission.

There’s One Problem AI Can’t Resolve: Implementation

Speaking, as we were last month, about artificial intelligence and its adoption into electronics design and manufacturing, we observed that a current obstacle to implementation is the use by vendors of customer data in order to build their models.

And while vendors insist the data are aggregated and anonymized, said customers, naturally, have been generally circumspect over the perceived cost of the lessons they have learned – often painstakingly – being used to enable competitors, not to mention ultimately paying those same vendors for the courtesy.

To that I will add the musings of Neil Thompson, who is the director of the future tech research project at MIT’s Computer Science and Artificial Intelligence Laboratory.

READ FULL ARTICLE

NCAB Acquires PCB Units of EPI Components Trade, DVS Global

BASSANO DEL GRAPPA, ITALY – NCAB Group in July announced the acquisition of the PCB division of DVS Global, an Italian electronics provider. The PCB distributor will pay SEK200 million ($18.6 million), with a possible further earnout of a maximum of SEK45 million ($4.2 million).

DVS was founded in 2003 and also has offices in Switzerland, Hong Kong and China. Annual sales of the PCB division in 2023 amounted to SEK230 million ($21.4 million), with sales primarily directed toward Italian customers in the industrial and automotive sectors.

NCAB is acquiring the PCB division of the company, while the previous owners will focus on the remaining division, Teknokit. The deal is expected to close in September and the sellers will stay during a transition period.

READ FULL ARTICLEZDT JV Signs Agreement to Develop Thai PCB Workforce

BANGKOK – Peng Shen Technology, a joint venture between Saha Group and Zhen Ding Technology, has initiated a collaborative project with Thai educational institutions to develop local talent for the country’s PCB manufacturing industry.

The company has signed cooperation agreements with five leading Thai educational institutions with a stated goal to increase Thailand’s share of the global PCB production and elevate its position to the forefront of the industry.

The company said the collaboration aims to achieve five key objectives:

READ FULL ARTICLEAPCT Relaunches as AdvancedPCB

AURORA, CO – Advanced Printed Circuit Technology, Advanced Circuits and San Diego PCB Design have combined to relaunch as AdvancedPCB.

“Since the founding of APCT in 1977, we’ve expanded operations and expertise through more than 10 acquisitions. At the same time, we’ve consistently teamed up with global leaders in PCB design, manufacturing, and innovation,” said Peter Austin, CEO, AdvancedPCB. “This new brand represents our commitment to powering the next generation of technology, from healthcare to aerospace and defense to consumer products.

“The semiconductor industry continues to grow quickly in North America and across the globe. American-made AdvancedPCB is well positioned to service this growth,” Austin added. “Our products and solutions extend through global markets, providing enterprises in myriad sectors outside of North America with the same range of security, reliability, and quality standards that customers within the United States have come to expect.”

Read Full ArticleAlba PCB Group Acquires WM Eltar

TARNOWSKIE GORY, POLAND – Alba PCB Group has acquired fellow printed circuit board fabricator WM Eltar, based here outside of Krakow.

Terms were not disclosed.

WM Eltar specializes in the production of single- and double-sided PCBs, aluminum and flex PCBs. Alba produces PCBs and offers R&D and engineering in Italy and China.

READ FULL ARTICLEWistron to Invest $25M in Latest Vietnam Campus

DONG VAN WARD, VIETNAM – Wistron is investing $24.5 million in a new campus for electronics assembly in northern Vietnam, local media are reporting, citing government filings.

Equipment installation for the 49,000 sq. m. campus in the Dong Van III industrial park is scheduled for November, with production beginning shortly thereafter.

According to reports, the plant will have an annual capacity of more than four million LCD displays, docking stations, webcams and other Internet-related devices.

READ FULL ARTICLEVariosystems Acquires Swiss EMS Firm

STEINACH, SWITZERLAND – Variosystems in June announced the acquisition of the EMS division of the Swiss electronics components manufacturer Schurter.

With the acquisition of Schurter Solutions, Variosystems said it has strengthened its European supply chain by adding a manufacturing site in Romania, and enhanced its engineering and rapid-prototyping capabilities via a second VARIOincubator hub in Mendrisio, Switzerland. The facility in Mendrisio will support and develop customers in Northern Italy, France and Switzerland, the company said.

The two added locations in Mendrisio and Gruiu, Romania, double Variosystems’ production capacity in Europe. The manufacturing site in Romania will focus on high-volume customer programs that require highest cost competitiveness. The site in Mendrisio will focus on engineering, rapid-prototyping and low-volume production services.

READ FULL ARTICLEStarteam Acquires Italian PCB Factory

HONG KONG – Starteam Global has acquired CTB Circuiti Stampati and its PCB manufacturing facility located in the Italian town of Flero.

The PCB manufacturer said the new factory has been rebranded as Flero Starteam, and amplifies its manufacturing capability and market presence in Europe. Starteam said Flero Starteam will concentrate on innovation through prototyping, sample production, specialized high-mix, low-volume manufacturing, quick turn, and customized requirements.

“This expansion is a milestone for Starteam, reinforcing the company’s presence in the heart of Europe and highlighting its dedication to serving its European customers in the most local and flexible way,” the company said in a release.

READ FULL ARTICLENano Dimension to Acquire Desktop Metal

WALTHAM, MA – Nano Dimension entered into a definitive agreement to acquire all outstanding shares of Desktop Metal for around $183 million.

Under the agreement, Nano Dimension will acquire all outstanding shares of the 3-D printing system provider in an all-cash transaction for $5.50 per share, subject to possible downward adjustments to $4.07 per share, for a total price of approximately $183 million, possibly down to $135 million in total with possible adjustments.

The transaction is expected to close in the fourth quarter of 2024, subject to the satisfaction of customary closing conditions.

READ FULL ARTICLEKitron to Build New Production Facility

ARENDAL, NORWAY – Kitron is planning a 7,500 sq. m. production facility here, with plans for completion during the first half of 2026.

“There is growth and a high level of activity at Kitron in Arendal, and we believe the activity will increase further in the years to come,” said Heine Østby, managing director of Kitron Norway. “We are simply outgrowing the current premises. Now we get the opportunity to help design the perfect building for our needs. This gives us the opportunity to grow further here in Arendal, where Kitron has its roots back to the 1960s. We are extremely happy about that.”

Kitron’s operations in the area are currently divided between a facility of 7,300 sq. m., in Kilsund, Norway, and 4,000 sq. m. of rented premises at Stoa. When the new facility is ready, the company will move its Stoa operations to the new site, while the plant in Kilsund will continue as is.

Garner Osborne Acquired by Entrepreneur

NEWBURY, UK – Garner Osborne, a UK-based specialist in PCB manufacture and assembly, has been acquired by entrepreneur Dean Curran through Novastone Capital Advisors’ Entrepreneurship Through Acquisition program.

Operating for more than 33 years, Garner Osborne delivers PCBs that include rapid prototyping, small- to medium-sized volumes, and large-volume offshore manufacture. The transaction provided an exit for founder and former CEO Mike Garner and his business partner Nigel Priest, with Curran stepping into the business as CEO and co-owner. Garner will remain a minority stakeholder in the company.

“I am grateful to Mike for trusting me to continue his legacy,” said Curran. “I have been hugely impressed by the operational excellence and extremely high-quality PCB products that Garner Osborne manufactures, supplying a diverse range of customer sectors. The business has great potential for growth.”

READ FULL ARTICLELava Considers Spinoff of Manufacturing Arm

NOIDA, INDIA – Lava International is reportedly considering a spinoff of its production arm into a separate company, which may generate business from other handset brands and help meet targets under the production-linked incentive scheme for smartphones.

The contract manufacturer, which has not been able to meet its PLI smartphone targets since the scheme began in 2020-21, is hopeful of a turnaround in its manufacturing fortunes with the upcoming incentive package for component production, head of manufacturing Sanjeev Agarwal told The Economic Times.

“Lava’s performance in the ongoing PLI scheme is an internal concern, and we are working on plans to bridge the gap,” he said.

READ FULL ARTICLEFIT Launches In-House Circuit Assembly Services

MILPITAS, CA – Flex Interconnect Technologies launched its own circuit board assembly service in June, bolstering support for product development initiatives throughout North America.

“We are thrilled to now offer in-house assembly,” said Chetan Shah, president and CEO, FIT. “We recognize the growing demand in the electronics market for quickturn, low-volume circuit assembly with exceptional quality and high yields.”

While reshoring has brought assembly work back to the United States, higher volume production orders take up existing assembly capacity, the company said. Product development teams can struggle to find low-volume solutions to meet their go-to-market timelines, and by focusing on low-volume projects with quickturn timelines, FIT said its offering fills a current hole in the market.

READ FULL ARTICLEChinese EDA Startup Slashes Workforce

NANJING, CHINA – X-Epic, a Chinese developer of electronic design automation tools, is rumored to be laying off 50% of its workers after struggling to gain ground in the EDA space.

The South China Morning Press reported that the firm is struggling in its mission to make up ground on the US firms that dominate the EDA space: Cadence, Synopsys and Mentor Graphics.

X-Epic was founded in March 2020 and raised $121.7 million while developing a suite of chip design software EDA tools covering areas such as digital chip verification, hardware simulation, system debugging, and cloud-based verification.

READ FULL ARTICLEPCD&F

Apple has been granted a US patent for a thin system-in-package with a shielded stepped mold.

BH will supply flexible printed circuit boards for the camera modules on Samsung’s new foldable phones.

Gold Circuit Electronics (Thailand) Co. in July signed a deal to acquire CESE 2 (Thailand) Co. for approximately NT$1.14 billion ($35 million).

LQDX signed a sales and licensing agreement with Kansai Denshi Industries for manufacturing support for next generation IC substrates and advanced PCBs.

Mobenus will move to Namchun Industrial Complex in South Korea by next year to mass-produce high-density circuit boards.

Read Full ArticleCA

Absolute EMS partnered with Ventiva to build its Ionic Cooling Engine (ICE).

Benchmark is constructing a new state-of-the-art facility in Guadalajara.

Bentec appointed Accurex Solutions manufacturers’ representative for its Prey UPI in India.

BTU International appointed E-Tronix representative in North Dakota, South Dakota, Minnesota, Iowa, Wisconsin and Illinois.

CAES was awarded a $172 million contract from Raytheon to support a major international missile program.

Read Full Article

PCD&F

George Dudnikov, an engineer and executive with Hadco, Sanmina and most recently Victory Giant, passed away in June at 66.

ECM PCB Stator appointed Dan Lisowsky vice president of its Industrial OEM Products Division.

Methode Electronics appointed Jon DeGaynor president and CEO.

SelecTech appointed Benjamin Smith director of sales.

Summit Interconnect appointed Bobby Johnson vice president of human resources.

Ventec Giga Solutions appointed Marc Ladle project manager.

CA

ACDi appointed Scott Law plant manager.

Amtech appointed Brett Petrill director of operations.

Farnell named Rebeca Obregon-Jimenez president.

Intervala appointed Florin Larion director of operational excellence.

Keytronic signed a consulting arrangement with Craig Gates, who retired as president and CEO on June 30.

Read full article

PCB West Keynote to Offer Path for Implementing AI in Electronic Design

PEACHTREE CITY, GA – Electronics design software architect Charles Pfeil will keynote the PCB West conference and exhibition in October, PCEA announced.

Pfeil’s talk, “AI Roadmap for PCB Layout: New Opportunities for PCB Designers,” illustrates the capabilities and methodologies that will be needed for AI success with complex PCB designs, with a focus on constraints, place and route. Success, he says, lies in balancing the growing capabilities of AI with the preservation of proprietary design knowledge and methodologies. His talk will take place Oct. 9 at 11 a.m. at the Santa Clara (CA) Convention Center.

“AI functionality for effective place and route of simple designs is currently available; however, using AI for place and route of complex designs is still in the first stages. But the ultimate goal of AI-driven PCB design tools is to replicate and potentially surpass the capabilities of experienced human designers, particularly for complex designs,” Pfeil notes.

Read Full ArticleSusy Webb to Present Webinar on PCB Design Techniques

PEACHTREE CITY, GA – Susy Webb will present a new all-day webinar titled “Effective PCB Design Techniques” on Sept. 10, sponsored by PCEA.

Webb, a senior designer with 40 years of experience across a variety of industry sectors, will share ideas for setup, planning, and procedures that lead to efficient board design.

The all-day online class will take place from 9 a.m. to 6 p.m. EST, with a one-hour break from 12 p.m. to 1 p.m. EST.

Read Full Article2024-25 Board of Directors Ballots Out

PEACHTREE CITY, GA – The ballot for the next PCEA board of directors term is available to members for voting. All PCEA members in good standing are eligible to vote for the board of directors.

In accordance with PCEA Bylaws, section 9.3, directors shall be elected at the annual meeting of the membership for two-year terms. In accordance with the association bylaws, candidates for the board of directors were solicited from the active membership earlier this year, and the PCEA Board’s Nominating Task Force has nominated candidates for each director position.

PCEA members may vote for up to 12 individuals for the board. The following link may be used to access the ballot: https://www.surveymonkey.com/r/pceaboard2024. The deadline for voting is Aug. 2.

Read Full ArticleGeneral. The PCEA annual meeting will be held Oct. 8 from 9 to 10 a.m. during PCB West at the Santa Clara (CA) Convention Center. An update on all association programs, plus the annual awards, will be presented.

Abstracts for next year’s PCB East technical conference are due Sept. 6. The conference, the largest of its kind in New England, will take place April 29 to May 2, 2025, in Boxborough, MA. The event includes a one-day exhibition on April 30. Submit abstracts here.

Portland, OR. The chapter will meet on Aug. 15 for a webinar on reverse engineering PCBs featuring Bill Loving of ScanCad International. Contact Stephen Schmidt at stschmidt@pcea.net for details.

Richmond, VA. We have interest in starting a local chapter here. Those interested should email mike@pcea.net.

San Diego. Our next meeting is scheduled for Aug. 20 from 11:30 a.m. to 1:30 p.m. The scheduled speaker is Mark Finstad, director of engineering at Flexible Circuits Technologies. Contact Luke Hausherr at lucashausherr@gmail.com for details.

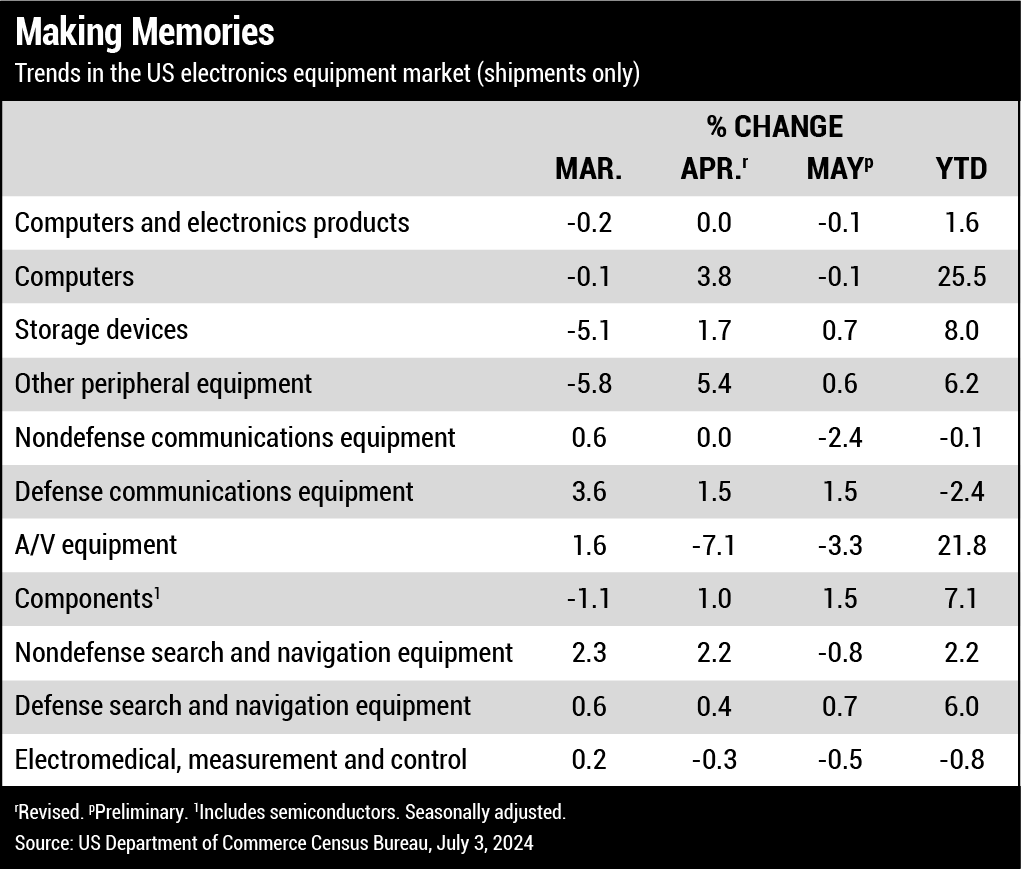

Dips and Dumps: Electronics Industry Wary of Demand, China

BANNOCKBURN, IL – Sentiment among electronics manufacturers fell in June but remained above its long-term average, according to IPC’s monthly supply chain report. Respondents noted concerns over possible dumping practices by Chinese companies.

The industry outlook remains strongly positive, though it has slightly softened over the two months from a record high in March.

The results are based upon the findings of an IPC survey conducted between May 15 and May 31. (more)

Hot Takes

Sales of PCB and MCM design software rose 2.8% year-over-year in the first quarter to $378.9 million. The four-quarter moving average, which compares the most recent four quarters to the prior four, for PCB and MCM rose 13.2% (ESD Alliance).

AI server shipments in the second quarter will increase by nearly 20% sequentially, and the annual shipment forecast has increased to 1.67 million units, representing 41.5% growth year-over-year. (TrendForce)

Second quarter PC shipments rose 1.9% from a year ago to 60.6 million units, the third consecutive quarter of year-over-year growth. (Gartner) (more)

The 3 ‘Cs’ of Success

The next generation of workers needs to understand how to be successful.

What we desperately need, or more specifically, what the West desperately needs is a generation of workers who understand and believe in the three critical “Cs” – commitment, concern and consistency.

The next generation – or generations – entering the workforce by and large offer impressive credentials. Tech savvy is one such attribute. It is especially important for an industry like ours to have employees who understand the technologies the industry produces. The current generation has also demonstrated an uncanny ability to multitask while using technology, which bodes well for the factory floor needs of the future. Regrettably, that is where the impressive credentials all too often end.

Alas, the next generation of shop floor employees too often demonstrates some not-so-impressive traits. Among these are poor communication skills – both writing and verbal – lackadaisical adherence to work schedule demands, and a lack of interest in what is happening up and down the process flow. Regrettably, these unimpressive habits transcend their impressive skills.

Read Full Article

Component Obsolescence Management

Ways to avoid redesign due to discontinued parts.

Electronics found inside infrastructure items such as buses, trains, signage, control units – anything that requires a printed circuit board assembly – are usually expected to have a long lifespan of continuous operation.

Each of those electronic systems and their corresponding subsystems can be affected by component obsolescence, however, especially when the components placed into them today have a purchase availability of only about 10 years.

This is because changes in design, improved component speed and efficiency, a drop in demand, etc. lead to component replacement and can make older components obsolete.

Read Full Article

Meeting the Challenge of EMS Workforce Shortages

Employee recruitment and retention require an active company effort.

It’s no secret that a tight labor market is an issue in all segments of the electronics manufacturing services (EMS) industry. A large part of this is the result of manufacturing offshoring trends. When I entered the workforce, I had friends and relatives who worked or had worked in manufacturing-related careers, influencing my choice to work for an EMS company. That isn’t the case today.

A few years ago, I participated in a local manufacturing awareness day targeted at high school students participating in their schools’ robotics programs. I put together a short video that illustrated manufacturing processes and careers in the EMS industry. Even students interested in engineering careers weren’t thinking about manufacturing engineering or hardware engineering. Most were focused on software engineering with an eye on getting jobs at Google or some other highly visible tech employer.

This underscores the value of educational outreach programs at the high school and community college level, when young people are making career decisions. Similarly, this also underscores the need for considering the lack of workplace familiarity that entry-level employees are likely to have in their first manufacturing job. One of my clients, Electronic Design & Manufacturing, is conducting that outreach and education successfully in its community, and I thought it might be a good example to share.

Read Full ArticleDesigning for Board Thickness

Small differences can have big consequences.

For as long as there have been printed circuit boards, the nominal thickness seems to have been set at 0.062″ – or in Latin, 1.5748mm, but call it 1.6mm for short. In practical terms, the standard dielectric materials available support this board thickness while providing anything from two to 20 layers. I imagine four layers is still the most common use case.

Larger boards will need more connections and require more stiffness. To manage connectivity and flatness requirements, standard PCB thickness targets ratchet up to 2.4mm and 3.2mm. On the low side we find 1.0mm and go down to 0.8mm. All these targets are related to using so-called gold fingers as a printed edge connector.

It’s about connectivity and solderability. This was handed down from the backplane and daughtercard configurations found in our tower computer systems. The motherboard has expansion sockets and the memory cards come with fingers to plug and play. As a result of this variety, many connector vendors that market to plated through-hole technology users will offer different pin lengths that fit the range of board thickness options.

Read Full Article

PCBs’ Green Evolution

The humble printed circuit board continues to change to meet new demands.

Power is nothing without control. It’s not a quote by a famous politician or social commentator, or even Mark Twain. It’s an advertising slogan for car tires. But it’s also an apt description of the opportunities for our industry that are now happening as part of the green energy transition.

Electrification is one of today’s dominant megatrends. The “old way” of releasing energy from traditional fuels by explosions and burning is giving way to alternatives like electromagnetic and photovoltaic conversion, as well as chemical processes inside batteries and fuel cells. Taking the utmost care of every joule is critical to maximize the harvest from the scarce ambient energy sources and to minimize waste throughout the conversion system, distribution infrastructure, storage and – ultimately – the load.

Exercising that care demands control. This is where more power electronics are being employed to ensure efficient and precise conversion as we accelerate the pace of electrification; changing traditional mechanical, hydraulic, and fossil-fueled tools and vehicles that we have all become accustomed to using into electrical equivalents that can be powered from clean and sustainable energy. Replacing conventional boilers with electric heat pumps for heating buildings is one example.

Read Full ArticleCustom Tailored or Off the Rack?

Much like a bespoke suit, PCBs require individual tailoring to meet a customer’s needs.

A printed circuit board is not a commodity and many in the electronics supply chain do not understand that. Buyers wanting “champagne at beer prices” leads them to press fabricators to devalue their efforts and work. Additionally, I have spoken with designers who have no idea how boards are made, but then turn around and speak with an air of authority that the fabricator should just “dial in the fabrication process” to etch a narrower trace on their board.

I am not sure what most buyers and designers have in mind of how printed circuit boards are manufactured, but a good analogy helps many to understand that boards are custom tailored, like a fine bespoke suit, and not a garment off the rack.

Now I realize a bespoke suit may be an analogy many wouldn’t understand without a bit of context. Bespoke means made specifically for one customer. To be sure, in the modern era of business casual and even casual attire in certain work environments, suits are a lot less common.

Read Full Article

Clock Spring Flex Designs

Rotating flex circuits are buildable, but will require additional considerations.

I have an application where I need to make an electrical connection to a rotating shaft. The shaft rotates approximately 180° in each direction. Can a flex circuit wrapped around the shaft like a clock spring accomplish this? Are there any guidelines to follow or ways to predict life expectancy?

While clock spring flex designs are not super common, they are certainly not rare either. I have had multiple successful clock spring flex designs over the years. Most of these initial designs probably would not have performed as desired in the “as received from customer” state, but with a little bit of guidance we tweaked the designs and they all ended up performing well.

Many significant variables must be considered, along with a few lesser features, and all need to be weighed to get to a successful design. A few of the big factors are:

- How many total cycles will the flex realistically need to function?

- Is the coil constrained by an outer housing as it unwinds?

- How fast is the winding and unwinding?

PCB Design. No Humans Required.

An electronics startup is developing AI-driven design software that lessens manual intervention.

by Mike Buetow

The role of artificial intelligence in PCB design is a growing topic of debate throughout the industry, with discussions ranging from the previous inadequacies of autorouting, the best methods for training it, and its potential to replace human designers.

We spoke in June with Sergiy Nesterenko, founder and CEO of a new software company called Quilter, whose goal is to accelerate hardware development by fully automating circuit board design. The former SpaceX engineer discussed why he thinks the margins designers build in are excessive and how Quilter’s AI-driven, physics-based platform can resolve and even violate some “human” rules while still generating superior printed circuit boards.

The following has been lightly edited for grammar and clarity.

Young Guns

The annual snapshot of the industry finds the PCB design workforce is – at last – skewing younger.

by Tyler Hanes

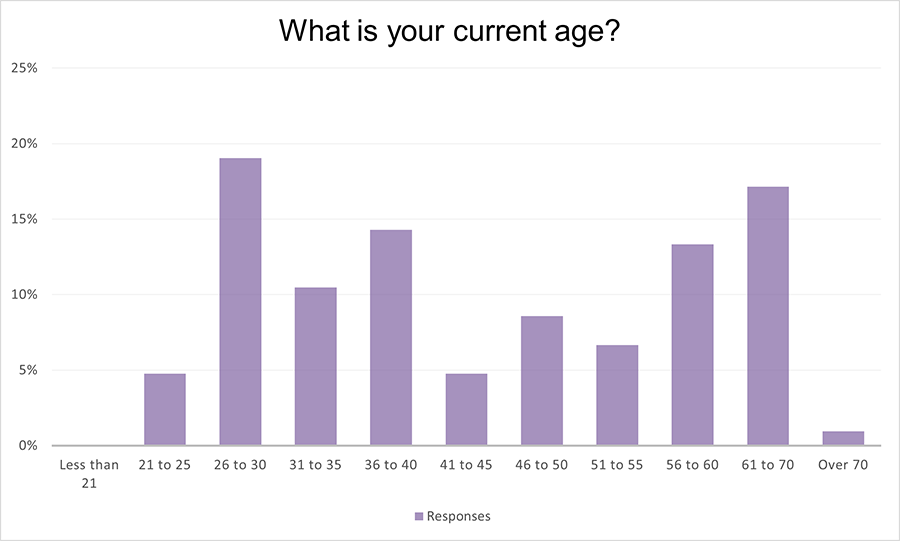

Is the PCB design workforce finally getting younger? After years of consternation from the PCB industry – and the country as a whole – about the daunting task of replacing retired or soon-to-be retired workers, those worries may be coming to a head as the workforce begins to skew younger.

That’s the suggestion of the annual PCD&F/CIRCUITS ASSEMBLY Designers Salary Survey.

After last year’s survey found the most respondents in the 61-70 age group, this year’s found the largest number of respondents from the 26-30 age range at 19% (Figure 1), edging out the 61-70-year-old group by two percentage points. Moreover, the overall response of designers and design engineers ages 40 and under was a tick higher than those ages 41-60. Balance is coming.

‘A Legacy of Innovation’

Indium Corporation celebrates its 90th anniversary with a look at its past and future innovations.

by Tyler Hanes

A sense of curiosity and discovery drove the founding of Indium Corp. in the early 1930s, and that continued drive to innovate has carried the company to success over the past 90 years of its existence – leading it to become a premier manufacturer and supplier for the PCB, semiconductor and thermal management industries.

After reaching the 90th anniversary milestone this year, the company is celebrating with the theme of “A Legacy of Innovation Fueled by Curiosity,” meant to reflect the technological breakthroughs and the people who have fueled them.

Stretching Solder Capabilities

Solder paste dispensing can solve the challenges posed by differing component sizes.

by Timothy O’Neill

While stencil printing has long been the cornerstone of applying solder paste, it faces limitations with extremely small or large components. This challenge underscores the need for adaptable and innovative solder paste application methods. Here we delve into the realm of advanced dispensing technologies, exploring solutions that can help overcome common production challenges.

Stencil printing, despite its efficiency, struggles with the dual extremes of component sizes – area array and bottom termination components continue to shrink, while connectors and other components may increase in size. This variance stretches the capabilities of stencil printing. Dispensing offers the advantage of infinite flexibility, capable of producing both minuscule and substantial deposits while seamlessly integrating into the existing SMT process.

For example, a 25-gauge dispensing needle has an inner diameter of 10 mils, or 0.25mm, and a length of 0.25″, or 6.35mm. If that tip were treated as a stencil aperture and its area ratio calculated, it would be 0.10, which is considered impossible on a stencil by a factor of five! Without the pressure of the dispenser and finer solder particles in the paste, nothing would get deposited onto the PCB. Figure 1 shows a typical 25-gauge needle producing a 15-mil, or 0.375mm, deposit with Type 6 solder paste.

Read Full Article

PCD&F

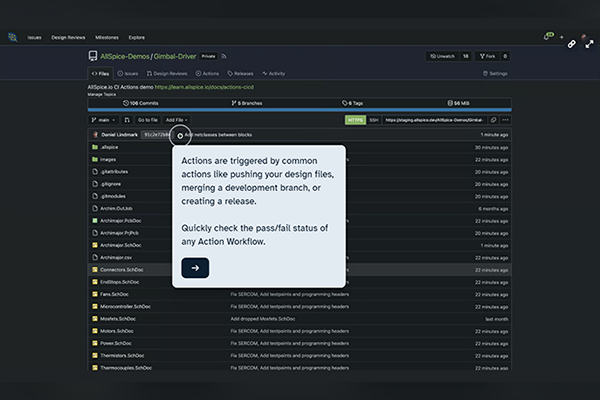

AllSpice Actions Automation Engine

Allspice Actions enables hardware teams to automate manual checks, validations and releases of electronics designs. Provides framework to build workflows that run tests automatically. Automates almost any manual steps a hardware engineer faces, such as verifying library parts, checking for design errors and packaging releases. Common use cases include generating bill of materials artifacts, automating static checks and reviews, checking part availability, calculating cost of goods sold and verifying parts in APL.

AllSpice

Altair HyperWorks 2024 Simulation

HyperWorks 2024 design and simulation software delivers significant advancements in AI-powered engineering and business, mechanical and electronics systems design, and simulation-driven design and optimization. Deepens AI capabilities, accelerates design exploration and iterations with generative design capabilities in Altair HyperMesh, conducts thermal analysis in Altair SimLab through “what-if” studies using real-world data from Altair physicsAI models to make design of experiments more efficient, rapidly predicts behavior with generative design in Altair Inspire to maximize efficiency in both design and manufacturing while ensuring performance, and improves training times.

Altair

CA

Indium Au-Based Precision Die-Attach Preforms

Indium’s high-reliability gold-based PDA preforms offer a high level of precision to reduce defects, control bondline thickness, and deliver high-yield performance and reliability in critical die-attach applications. Features include highly accurate thickness control, precise edge quality, optimized cleanliness, and default waffle pack method. Are available in the following alloys: primary – 80Au/20Sn, 79Au/21Sn; development – 78Au/22Sn, 77Au/23Sn, 76Au/24Sn, 75Au/25Sn, 88Au/12Ge, 96.8Au/3.2Si, 82Au/18In.

Indium Corp.

Indium PicoShot NC-6M Solder Paste

PicoShot NC-6M is a no-clean, halogen-free, Type 6 powder-size material specifically formulated to be compatible with Mycronic jetting systems and Mycronic’s “small dot” ejector. Is chemically compatible with Indium8.9HF series of solder pastes and is said to have been extensively tested to provide fine-dot jetting performance. Delivers dot volume of 1.6nl/dot, 230µm diameter, precision deposit (x,y targeting), long usage (stencil life more than 8 hr.), and minimal satellites.

Indium Corp.

In Case You Missed It

Additive Manufacturing

“A Novel Method of Incorporating CNT into Additive Manufacturing Electronics Dielectric Material”

Authors: Daniel Slep and Fan Yang

Abstract: Flexible hybrid electronics parts that are additively manufactured offer greater flexibility in geometry, complexity, and variety or customizability. In this work, UV-curable dielectric materials for additive electronics and incorporated carbon nanotubes (CNTs) within a formulated UV/LED curable matrix were used. It is shown that inkjet printing CNT mixture in specific manner with a commercial UV-curable dielectric improves mechanical and thermal properties of the final dielectric compared to the dielectric without the CNT mixture, including a significant decrease in coefficient of thermal expansion, while keeping excellent electrical properties. (Journal of Surface Mount Technology, July 2024, https://doi.org/10.37665/5ng0w157)

Read full article