June 2024

This issue of PCD&F / CA brought to you by:

PCEA

PO BOX 807

AMESBURY, MA 01913

PCEA BOARD OF DIRECTORS

Stephen Chavez, CHAIRMAN

Justin Fleming, SECRETARY

Gary Ferrari, CHAIRMAN EMERITUS

MEMBERS

Michael Buetow

Tomas Chester

Douglas Dixon

Richard Hartley

Scott McCurdy

Anaya Vardya

Susy Webb

Eriko Yamato

pcea.net

PUBLICATION

- PCD&F/Circuits Assembly digital.pcea.net

WEBSITES

- PCD&F pcdandf.com

- Circuits Assembly circuitsassembly.com

NEWSLETTER

- PCB Update pcbupdate.com

PODCASTS

- PCB Chat pcbchat.com

EVENTS

- PCB West pcbwest.com

- PCB East pcbeast.com

EDUCATION

- PCB2Day pcb2day.com

- PCEA Training pceatraining.net

- Printed Circuit University printedcircuituniversity.com

AWARDS PROGRAMS

- Service Excellence Awards circuitsassembly.com

- NPI Awards circuitsassembly.com

pcdandf.com

DATABASE

- Directory of EMS Companies circuitsassembly.com

mike@pcea.net

frances@pcea.net

Peter Bigelow, Robert Boguski, John D. Borneman, John Burkhert, Jr., Stephen Chavez, Geoffrey Hazelett, Mark Finstad, Jake Kulp, Nick Koop, Alun Morgan, Susan Mucha, Greg Papandrew, Chrys Shea, Jan Vardaman, Gene Weiner

production@pcea.net

nathan@pcea.net

frances@pcea.net

will@pcea.net

frances@pcea.net

mike@pcea.net

jacqueline@pcea.net

PRINTED CIRCUIT DESIGN & FAB/CIRCUITS ASSEMBLY is distributed without charge to qualified subscribers. To subscribe, visit pcdandf.com or circuitsassembly.com and click on Subscribe.

For changes or cancellations to existing subscriptions: subscriptions@pcea.net

PRINTED CIRCUIT DESIGN & FAB/CIRCUITS ASSEMBLY is published monthly by Printed Circuit Engineering Association, Inc., PO Box 807 Amesbury, MA 01913. ISSN 1939-5442. GST 124513185/ Agreement #1419617.

© 2024, by Printed Circuit Engineering Association, Inc. All rights reserved. Reproduction of material appearing in PRINTED CIRCUIT DESIGN & FAB/CIRCUITS ASSEMBLY is forbidden without written permission.

A Modern-Day Manhattan Project?

Should components for military use be made in a dedicated secure facility?

That’s the basic thinking behind a $3.5 billion allocation by the US government to support an undisclosed chipmaker, presumably Intel, to develop a classified advanced semiconductor development project. The monies at the root of the issue touched off yet another question, that is, whether Chips Act funds were misused when routed to the so-called Secure Enclave program.

The Chips Act, of course, is the foundational legislation upon which the US strategy of reclaiming semiconductor manufacturing dominance is built.

READ FULL ARTICLE

US Projected to Triple Semiconductor Manufacturing Capacity by 2032, SIA Reports

WASHINGTON – The US will triple its domestic semiconductor manufacturing capacity from 2022 – when the Chips Act was enacted – by 2032, the Semiconductor Industry Association projects in a report released in May.

The projected 203% growth is the largest projected percent increase in the world over that time.

Developed in partnership with the Boston Consulting Group, the study, titled “Emerging Resilience in the Semiconductor Supply Chain,” also projects the US will grow its share of advanced logic (below 10nm) manufacturing to 28% of global capacity by 2032, up from 0% in 2022. Additionally, America is projected to capture over one-quarter (28%) of total global capital expenditures from 2024-2032, ranking second only to Taiwan (31%). In the absence of the Chips Act, the US would have captured only 9% of global capex by 2032, according to the report.

READ FULL ARTICLETPCA Releases Guide for Energy Conservation and Carbon Reduction

TAOYUAN CITY, TAIWAN – The Taiwan Printed Circuit Association has published the “Guide to Energy Conservation and Carbon Reduction for PCB Factory Facilities and Process Equipment” as a resource for companies in the transition from strategic planning to actual implementation of the net zero initiative.

The guide recommends implementing the process in three phases – start, middle and end.

The start phase requires a full understanding of factory operations, including taking an inventory of each component’s efficiency, digitizing data from large energy-intensive equipment, and transparency of production scheduling.

READ FULL ARTICLEOlympic Circuit Technology to Build Thai Factory

HESHAN, CHINA – Olympic Circuit Technology has announced plans to invest up to $200 million to build a factory in Thailand to meet demand from existing and potential overseas clients.

The Chinese PCB fabricator said the new facility in Thailand will allow more flexible handling of likely adverse impacts from macro environment fluctuation, adjustments of industry policies, and the international trade landscape.

OCT has two PCB bases in China’s southern Guangdong province with an output of 4.2 million sq. m. of various PCB types last year. It ranked 36th in Dr. Hayao Nakahara’s annual NTI-100 list of the world’s largest 40 PCB fabricators.

Read Full ArticleEmerald Technologies Acquires Optimum Design Associates

SAN JOSE – Emerald Technologies in May announced its acquisition of Optimum Design Associates, an electronics design and engineering services company. Terms were not disclosed.

In making the announcement, Emerald Technologies also said that it has rebranded its name and has relocated its corporate headquarters to San Jose, which reflects the company’s continued evolution as a value-added partner to the world’s leading companies, providing mission-critical and highly complex electronic solutions across diverse end-markets and applications.

Optimum had been sold in March 2023 to Tempo Automation, but the deal collapsed due to financial issues at Tempo.

READ FULL ARTICLEThailand BOI Expands PCB Manufacturing Incentives

BANGKOK – Thailand’s Board of Investment has approved an expanded definition of PCB businesses to further promote foreign investment in PCB manufacturing and cover the entire supply chain.

In 2023, the BOI approved investment promotion benefits to PCB projects by some 40 companies representing a combined investment of $2.66 billion, or around 96 billion baht. The project applications came from companies based in China, Taiwan and Japan moving their PCB production hub to Thailand, as well as from Thai companies.

The expanded definition of PCB businesses now includes manufacturers of parts and providers of related services such as lamination, drilling, plating, routing and electrical testing, as well as the producers of PCB parts such as copper clad laminate, flexible copper clad laminate and prepreg, plus the producers of raw materials such as dry film, transfer film and back up board.

GPV Opens Expanded Factory in Thailand

VEJLE, DENMARK – GPV Electronics has opened a refurbished factory building in Thailand, adding 7,000 sq. m. (75,347 sq. ft.) of floor space to its existing 15,000 sq. m. facility.

“We are very proud of our new additional capacity in our electronics factory,” said Bjorn Fiskers, managing director at GPV Electronics TH and GPV Mechanics TH. “Now, the next step is re-layout of the existing production and the new area. We are eager to take the new building into use and to start serving our customers from the new facilities.”

The refurbishment took place inside GPV’s previous mechanics factory, located in the same building as its electronics facilities, and gathers the 22,000 sq. m. of electronics production under one roof. In 2023, the company moved its mechanics production into a new factory building near the electronics factory.

READ FULL ARTICLEFoxconn Reaffirms WI Commitment

RACINE, WI – Foxconn in May stressed its commitment to its Wisconsin operations after Microsoft broke ground on a $3.3 billion data center on a site originally intended for Foxconn.

Foxconn originally announced a $10 billion investment in southeast Wisconsin in 2017, but later scaled back that investment. In 2021, it said it would invest $672 million at the site and forecast 1,454 new jobs, down from the 13,000 that were originally promised.

“Foxconn Wisconsin is a key manufacturing site for data servers,” the company said in a statement. “Our global market share in servers is approximately 40%. Our Wisconsin operations greatly contribute to that market leadership. We are proud of the over 1,000 men and women who work at Foxconn Wisconsin and help make that happen.”

READ FULL ARTICLEAurelius Breaks Ground on Malaysian EMS Plant

KULIM, MALAYSIA – Aurelius Technologies has begun construction of a new manufacturing plant in Kulim Hi-Tech Park.

The plant, called P5, will be operated by Aurelius’ subsidiary BCM Electronics and is planned to be complete by the end of 2024. The facility will feature 243,000 sq. ft. of advanced manufacturing and R&D space – including nearly 13,000 sq. ft. of clean room facilities, BCM said in a release.

“P5 sets the stage for Aurelius to introduce advanced manufacturing capabilities targeted for automotive components and advanced Internet of Things applications,” BCM said.

READ FULL ARTICLEACDi Acquires 4th East Coast Manufacturing Plant

FREDERICK, MD – ACDi expanded its presence on the East Coast with the acquisition of a manufacturing plant in Kilmarnock, VA.

The company said it signed an asset purchase agreement with QinetiQ to acquire its Virginia facility and assets, including SMT and related assembly equipment. The deal brings ACDi to four East Coast locations with a total of nine SMT lines.

The facility purchase also includes the addition of all manufacturing employees and several new customers. ACDi will continue to build product for customers previously served at the Virginia location and said it plans to add new customers and personnel to meet growing demand for its capabilities.

READ FULL ARTICLEInstrumental Enters Defense Electronics Space

PALO ALTO, CA – Instrumental has announced its entry into the defense electronics industry with an ITAR-compliant environment for its manufacturing data and AI platform.

Integrating AI into the manufacturing process has become increasingly important in accelerating product launches, ensuring quality, and optimizing engineering time, Instrumental said in a release, and with its new AWS GovCloud environment, defense companies can securely extend their digital thread while leveraging AI to accelerate issue resolution, automate inspection, and deliver products on time while increasing yield.

“Instrumental’s technology has been battle-tested by the most admired electronics brands in the world. We are excited to be able to extend this technological advantage to defense and aerospace manufacturers to support their ambitious missions,” said Anna-Katrina Shedletsky, Instrumental cofounder and CEO.

Report: Plexus to Close Oregon Plant

GRESHAM, OR – Plexus in April reportedly notified Oregon officials of plans to close its contract electronics manufacturing factory here by this fall.

The plant’s entire staff of 75 will be let go, the reports said.

No reasons were provided for the closure.

According to the report, Plexus told the state the layoffs could begin in late June and continue through the end of October.

Nortech Systems to Close MN Manufacturing Plant

MINNEAPOLIS – Nortech Systems announced plans to close its manufacturing plant in Blue Earth, MN, by the end of the year.

In the company’s first quarter earnings call, CEO Jay Miller said Nortech will be shifting its wire and cable assembly and system-level assembly manufacturing to its Bemidji, MN, location, and all employees at the Blue Earth facility will be offered jobs at the company’s other Minnesota facilities.

Miller said the Blue Earth facility is an older, less efficient plant, and the Bemidji facility is newer and certified for aerospace and defense.

READ FULL ARTICLEPCD&F

DRAM manufacturers are pushing ahead with the development of DDR6, with planned data speeds of up to 17,600MT/s and the potential to reach 21,000MT/s or DDR6-21000.

Entegris has terminated its distribution agreement with MacDermid Alpha Electronics Solutions in exchange for $200 million.

Researchers at the University of Helsinki have developed sustainable dissolution methods for dissolving gold, silver and copper from recycled electronic materials.

Kingboard Laminates has notified customers of immediate price hikes to reflect growing raw materials costs, according to industry sources.

Kinwong joined the High Density Packaging User Group.

Read Full ArticleCA

Adamson is nearing completion of a $4 million electronics production facility featuring a Fuji high-speed PCB assembly line.

AIM Solder named Shinil Fl distributor in Korea and Cluff & Associates representative in Colorado, Utah, and Wyoming.

Altus will distribute PVA’s PathMaster X software.

BAE Systems received a $12 million DARPA contract to develop enabling technologies for computer-aided battle planning and is partnering with Boeing to provide EW systems for the F-15E jet fighter-bomber in a $19.1 million order.

Bendix will expand and upgrade its Indiana electronics manufacturing and distribution operations.

Read Full Article

PCD&F

Amitron appointed Lance Riley head of sales and operations.

APCT appointed Rich Halvas CFO.

Curtiss-Wright named Justin Fleming electrical engineer.

DuPont named CFO Lori Koch to succeed Edward Breen as CEO.

Ventec Giga Solutions appointed Leigh Allinson commercial director.

CA

Anthony Peter Bonadero is said to in line to be Compal’s next president.

Inovaxe appointed Jorge Gonzalez Mexico regional sales manager.

Integrated Micro-Electronics named Louis Sylvester Hughes chief executive officer.

Jabil appointed Michael Dastoor CEO to replace Kenny Wilson, who was placed on leave in April and will not be returning to the position.

Keytronic named Scott Hitt VP business development & strategic accounts.

Read full article

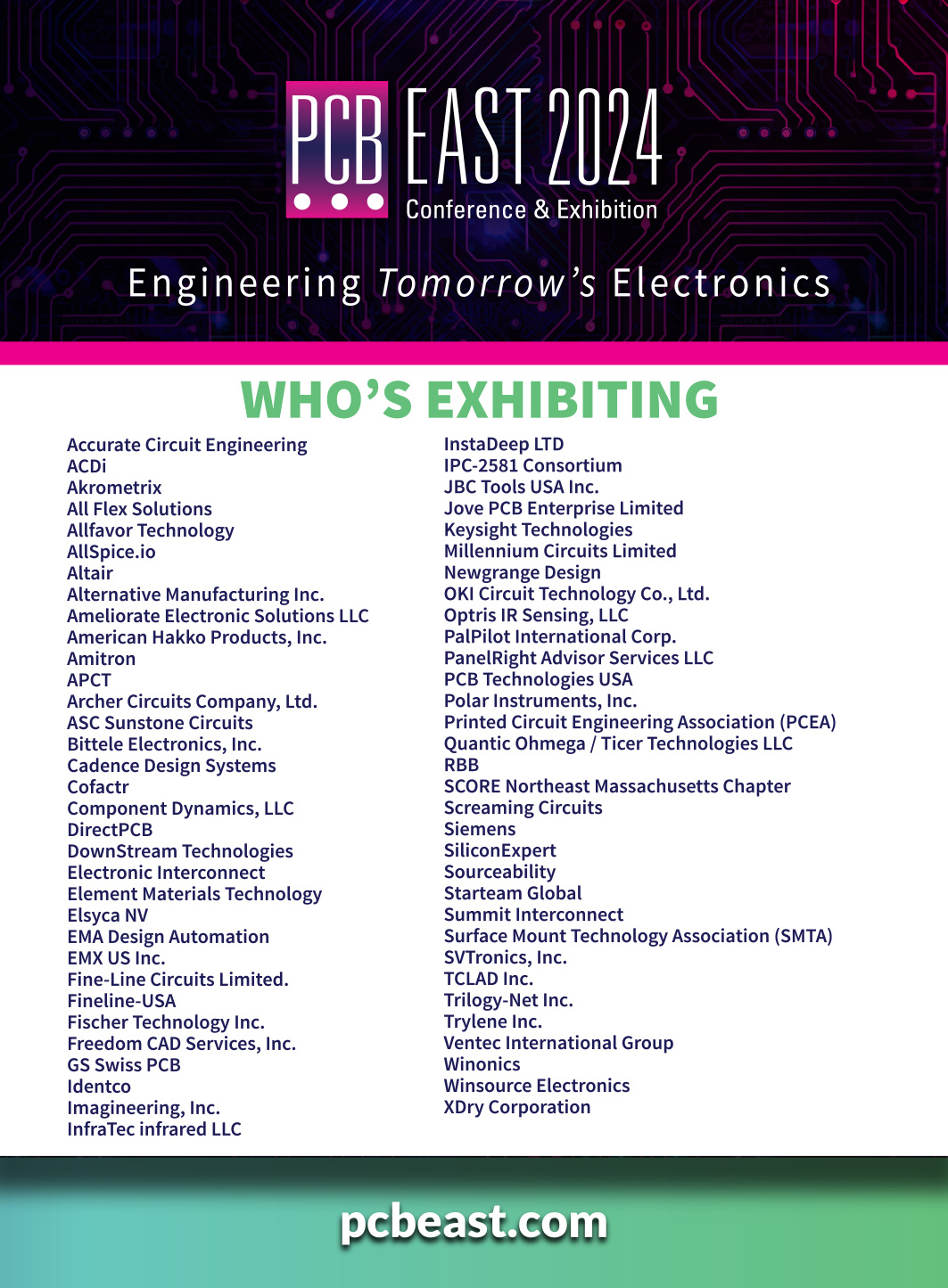

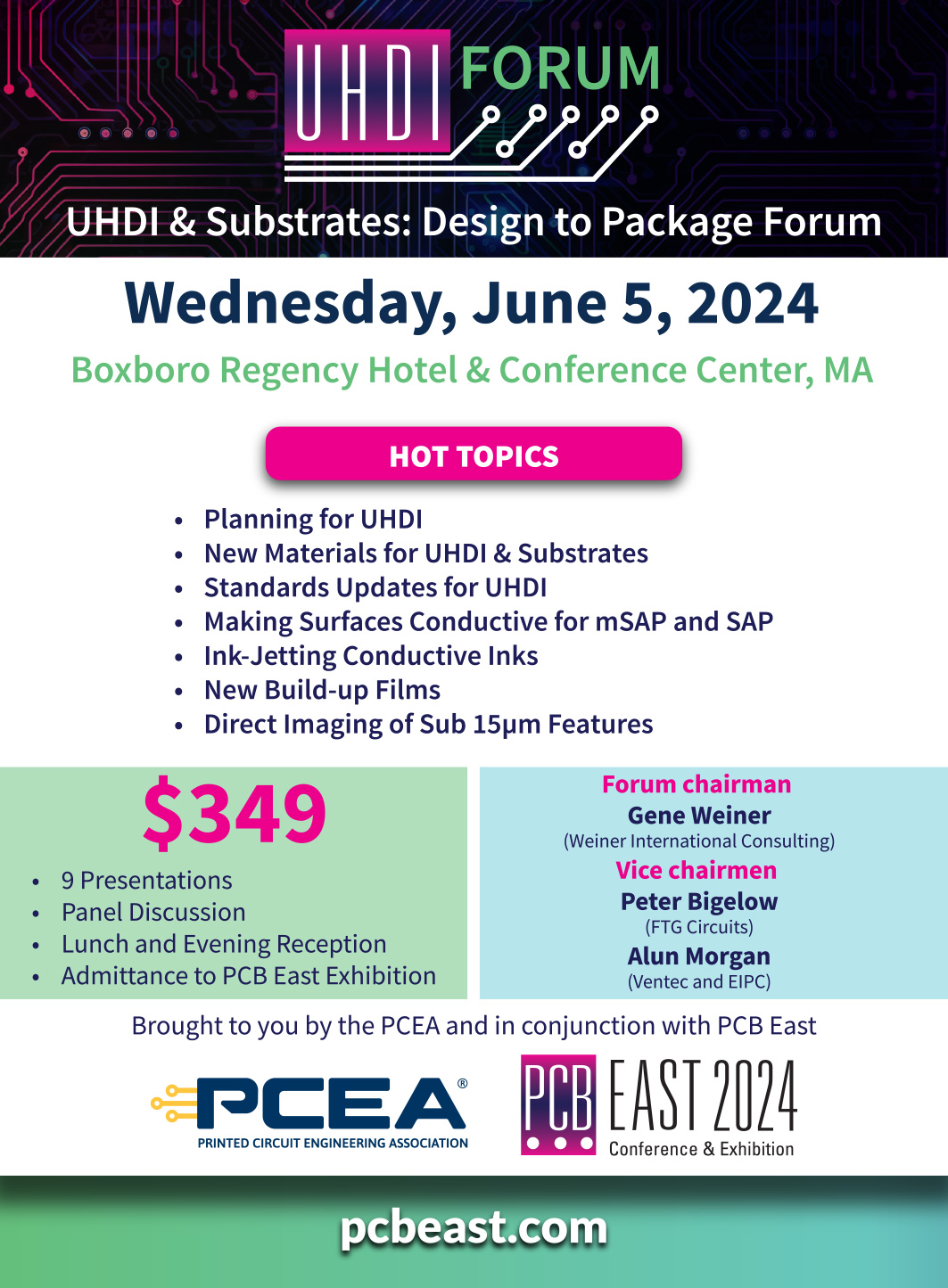

PCB East Free Technical Sessions Target AI, Designing for Assembly

PEACHTREE CITY, GA – Registrants for the PCB East exhibition this June will gain access to eight free technical sessions ranging from printed circuit design to fabrication and assembly. The sessions take place on June 5 at the Boxboro Regency Hotel and Conference Center in Boxborough, MA, and cover topics about AI and PCB design, strategic design PCB assembly, flex design, surface finishes, and more.

“Free Wednesday” starts off with a session on “Controlling the Waves: A Field-based Perspective on High-speed PCB Design,” taught by Daniel Beeker, technical director at NXP Semiconductors.

PCB East to Offer Free Expert Advice Sessions

PEACHTREE CITY, GA – Experts in printed circuit design and manufacturing will be on hand at PCB East 2024 to answer attendee questions during the exhibition on June 5.

Among the industry experts who will be available are Troy Hopkins (PCB design/layout), Lauren Waslick (flex design), Ethan Pierce (thermal management), Tomas Chester (design certification), and John Watson (libraries).

The experts will be available at scheduled times at PCEA booth 409 during the show hours of 11 a.m. to 5 p.m.: Hopkins (11 a.m. to 12 p.m.), Waslick (1 p.m. to 2 p.m.), Pierce (2 p.m. to 3 p.m.), Chester (3 p.m. to 4 p.m.), and Watson (4 p.m. to 5 p.m.).

Read Full ArticlePCD&F Opens Annual PCB Designer Salary Survey

PEACHTREE CITY, GA – PCD&F is conducting its annual salary survey of printed circuit board designers, design engineers and other layout specialists.

PCD&F surveys designers and design engineers each year, asking questions related to annual salaries, job functions, experience, education, job satisfaction, and ECAD tools used, among other data.

The survey can be taken here: https://www.surveymonkey.com/r/2024pcdfdesignerssalary.

Read Full ArticlePfeil Updates ‘Constraints’ Handbook

PEACHTREE CITY, GA – Many printed circuit layout designers are looking for ways to determine if a digital signal requires high-speed management and to offer a range of constraint values and layout methods to mitigate or eliminate the problems. Charles Pfeil’s latest edition of High-Speed Constraint Values and PCB Layout Methods offers a relatively simple framework for making those determinations.

The new edition, version 3a, includes updates regarding triplets from Daniel Beeker, who originated the concept, and corrects the TPD values in this document and the calculator for differential pairs on stripline layers as identified by Liora Hertzog from Xsight. It is available here: https://pcea.net/resources.

The book, which Pfeil first published in 2019, has extensive detail on timing, crosstalk, vias and routing. An accompanying calculator helps users resolve microstrip and stripline trace couplings and phase matching.

Read Full ArticleTech Visionary Harold Moss to Keynote PCB East 2024

PEACHTREE CITY, GA – Technology visionary Harold Moss will keynote the upcoming PCB East technical conference with his address, “Embracing AI in Electronic System Design: Shaping the Future with Confidence.” Moss is renowned for his expertise in AI, cloud computing, cybersecurity and emerging technologies, having launched major programs at IBM, EMC and other major OEMs.

Moss will speak at 11 a.m. on June 5 at the Boxboro Regency in Boxborough, MA.

As we stand on the precipice of the AI revolution, integrating artificial intelligence (AI) into electronic system design represents a pivotal moment in the evolution of technology. In this keynote address, Moss will delve into the profound impact of AI on electronic system design and explore why embracing this transformative technology is not just advantageous but imperative. From streamlining design processes to optimizing performance and reliability, AI holds the potential to revolutionize every aspect of electronic system design. Moss will address common misconceptions and fears surrounding AI, emphasizing its role as an enabler of innovation rather than a threat to human creativity and ingenuity.

Read Full ArticlePCB West 2024 Opens Technical Conference Registration

PEACHTREE CITY, GA – Registration is open for the technical program for PCB West 2024, featuring more than 110 hours of in-depth electronics engineering training spread over nearly 50 sessions.

Among the industry experts scheduled to speak this year are Lee Ritchey, Susy Webb, Zachariah Peterson, Tomas Chester, John Watson and Charlene McCauley. The conference will be held Oct. 8-11 at the Santa Clara (CA) Convention Center and features classes for every level of experience, from novice to expert.

The scope of classes ranges from designing all types of printed circuit boards to complex signal and power integrity and power delivery systems design. Foundational topics such as circuit grounding and PCB stackups are interspersed with advanced tutorials on DDR5, thermal management, analog measurements, system mechanical design, and more.

Read Full ArticleBoston. We are grateful to Gopu Achath of EMA Design Automation and Paul Yang of Jove PCB, who gave talks on embedded inductor technology and on supply chain-driven circuit design, respectfully, at our May kickoff meeting. We are planning to hold our next meeting in July via Zoom.

Portland. On May 16 we welcomed Tom Hausherr from PCB Libraries as a guest speaker on “PCB Design Perfection Starts in the CAD Library.” The next meeting is June 13 at 12 p.m. Pacific. Two main topics are scheduled: IPC-2581 vs. Gerber and AI in PCB Design. Contact Stephan Schmidt at stschmidt@pcea.net for an MS Teams invitation. Also, while most of our meetings are online, we are looking for a facility to host an in-person meeting on Oct. 24.

Silicon Valley. A venue is arranged for a June 20 meeting. Contact Bob McCreight at bob.mccreight@outlook.com for details.

Q1 EMS Deals Slip, but M&As Expected to Rise Over Time

CHICAGO – Nine EMS transactions took place in the first quarter, one less than reported in the first quarter of 2023, Lincoln International recorded in its latest EMS Quarterly Review.

Of those transactions, four were EMS consolidations, while vertical/horizontal convergence accounted for five of the transactions, the highest number of vertical/horizontal transactions in the previous three years.

By geography, Europe had four transactions, Asia had three transactions, and two were cross-border transactions. US/Canada did not record a closed transaction in the quarter. (more)

Hot Takes

Smartphone and PC shipments will each show growth of around 2% this year, driving small unit shipment growth in all package categories. (TechSearch International)

North American EMS shipments in April fell 2.1% compared to the previous year, and decreased 1.9% sequentially. Bookings rose 33.6% year-over-year and increased 16% over March. (IPC)

New US tariffs on Chinese imports – including a 50% duty on semiconductors – have accelerated a shift in supply chains toward Taiwanese wafer fabs. (TrendForce) (more)

Connecting the World

What to make of the technology that unites industries and those who run them.

While concerns still abound, life has returned to some semblance of normal in the post-Covid world. While most were hunkered down for months or years thanks to restrictions on travel and social distancing protocols, those times are now behind us and, at least in my case, I am traveling as much as ever. While glad to be able to travel once again and see people in person, I have been reintroduced to many of the accompanying irritants, such as long lines at airport security and flight delays caused by weather or tardy flight crews. On the positive side, however, I am continually reminded of how it truly is really a small, small – and interconnected world – after all.

During the worst of Covid, I thought the world was small thanks to technologies such as Zoom, Teams, etc., that enabled people from virtually anywhere on the globe to communicate and be seen – in real time – by colleagues, friends or family via a few simple keyboard clicks. While not the same as being in person, the technology enabled the next best thing – instantaneous interaction.

While in the airport security lines, waiting for a flight, or dining in restaurants after a long day, however, I am amazed at the copious amounts of technology that make travel easier, enable portable communication, and provide entertainment. And all this technology is being embraced by people of all generations, regardless of background.

Read Full Article

Navigating Rising Material Costs

Take proactive steps to minimize the impact of growing material prices.

Overseas board manufacturers have received formal notifications from major laminate suppliers about upcoming double-digit price increases for the raw materials required to produce printed circuit boards.

Compared to this time last year, gold and copper prices have risen significantly due to inflation, the push for green energy, and speculative demand and capacity limitations for these precious metals in the coming years.

While most notifications were heavy on apologies but light on details, one was specific about the increases:

- Copper and copper foil: up 30%

- Tin: up 40%

- Gold: up 35%

Setting Customer Expectations

Know the “whys” behind each clause in the manufacturing agreement.

Partnership is one of the most hackneyed terms in the electronics manufacturing services (EMS) industry. It often gets used to describe business relationships that are anything but partnerships. At the same time, the best EMS relationships actually are partnerships where parties have a symbiotic relationship beneficial for both companies. What drives these different relationships in the same business model? Often the answer is the program manager.

Back when outsourcing was a new concept, the most experienced employees at an original equipment manufacturer (OEM) were assigned the responsibility for the relationship. In many cases, those executives had manufacturing as well as purchasing experience. When demand or allocation surprises occurred, these experienced teams worked together for a good resolution in most cases. Today, contract manufacturing is just one more thing that most OEM purchasing departments source and manage. Buyers may or may not have ample experience managing EMS suppliers, particularly given the volume of turnover in these roles. Less experience translates to a focus on unit price, less ability to understand the impact of errors in forecasting, and difficulty in understanding issues that excess material creates.

The Need for Speed

Put the pedal to the metal in your PCB layouts.

Printed circuit board design evolves over time and the rate of the evolution is not slowing. High-speed digital design becomes a key topic as we move forward.

By the time you read this, I’ll be officially old. Early retirement age is 62 and I was born in ’62 so I’m eligible for those senior discounts. One of the things that happens as we age is time seems to go by even faster. We’ve seen so much, less is novel. We’re not plowing new furrows but rather deepening ones we’ve tracked before.

I say that to say this: Circuits keep switching faster all the time. What worked in my early days no longer gets it done. My first computer didn’t have a hard drive. It had two floppy disk drives, and they were the ones with 360KB rather than the smaller, stiffer 1.4MB. I had DOS on one floppy and a modem driver on the other. The baud rate was a blazing 1,200B.

Read Full Article

The Era of Ultra-High-Density Interconnect Topologies Has Begun

But with it comes signal integrity and thermal issues.

Ultra-high-density interconnect (UHDI) topologies support the creation of electronic circuits with unparalleled wiring density, enabling the creation of compact yet powerful electronic devices. This month, we’ll touch on the complexities of UHDI design, the crucial role of verification methods, and the multifaceted challenges inherent in pushing the boundaries of electronic miniaturization.

Designing UHDI topologies demands a delicate balance of several factors. It begins with understanding the unique wiring density requirements dictated by the specific application and IC packaging, as well as the capabilities of the PCB fabricator. Whether for consumer electronics requiring sleek designs or aerospace systems demanding robustness, tailoring wiring density is paramount.

Achieving high wiring density alone isn’t enough, however; ensuring signal integrity is equally critical. In densely packed circuits, risks of interference and crosstalk loom large, threatening overall system performance. Meticulous planning and layout optimization are essential to mitigate these challenges.

Read Full Article

Expanding Tech Access

Our passion for technology can improve services and life experiences for everyone.

Many of us working in the electronics business, wherever we are in the value chain – from design to manufacturing, as well as marketing, sales and support – are more than simple creators of technology. We are also fans, adopters and evangelists. As a species, we have always pursued technologies with the goal of making our lives better.

It’s in the interest of humanity that more people can use the technologies we create. Many powerful technologies that define the world we live in today began life as the invention and plaything of a small number of expert users: search engines, digital image sensing, blockchain, AI, even the internet itself, started this way but have become widely used to the advantage of all. This technological democratization is not a new phenomenon. The invention of the printing press is often cited as an early example. In addition to expanding and accelerating the spread of information, its arrival also enhanced the accuracy of the data shared by reducing human error.

For as long as there is invention, action will be needed to mitigate the divide that separates the technological haves and have-nots. The World Economic Forum points out that digital technologies are a driver for fairness and justice, and that equalizing access is essential to safeguard security and human rights. We can celebrate the fact that information services, banking, e-government, and e-health are already widely available and affordable, even in regions that have minimal fixed infrastructures.

Read Full Article

Via Viability

Flex and rigid-flex can handle all via types – with some considerations.

We have talked before about vias, but some situations can trip you up in flex and rigid-flex, and some tricks can be exploited to overcome them. When it comes to rigid-flex and flex, keep in mind these things.

To start – yes, you can put a microvia in a flex laminate. In fact, I would argue that in an apples-to-apples comparison, a microvia in flex laminate will be more reliable than in rigid reinforced laminate. There are a few reasons for this. One is, the thin flex cores enable low aspect ratio vias, which has been proven to improve reliability.

Flex microvias can also take advantage of certain material attributes. Because flex laminate is a homogenous film without any reinforcement, it lasers very cleanly and the side walls of the hole are uniform. Without any glass weave, the laser cuts through the dielectric evenly, reaching the target pad at the same time with the same power level across the pad. This results in a consistent target pad surface for plating.

Read Full Article

Measuring Quality Over Time

Using the Weibull distribution to model gold wire bonding on ENEPIG.

by Patrick Valentine, Ph.D.

The most used distribution in reliability analysis may be the Weibull distribution. Its genesis can be traced back to Waloddi Weibull’s invention in 1937. Then, in 1951, Waloddi presented his hallmark paper to the American Society of Mechanical Engineers (ASME) on this subject, claiming that his distribution applied to a wide range of problems. He showed several examples, ranging from the fiber strength of cotton to the fatigue life of steel.1

The Weibull distribution is versatile and fairly easy to interpret. It can be used to model a wide range of applications in engineering, medical research, quality control and finance. For example, the distribution is frequently used with reliability analyses to model time-to-failure data. It is also used to model skewed process data in capability analysis.

The Weibull distribution may not always provide the best fit for a data set. It may not work as effectively for product failures caused by chemical reactions or degradation; e.g., corrosion. These situations can occur with semiconductor failures. Usually, in these types of situations, the lognormal distribution is used.

Read Full Article

Measuring Reflow Oven Performance (or Mind Your U2RZY3Cs)

A thermal processing expert’s take on which tests are ideal for comparisons.

by Fred Dimock

I get asked how I would evaluate the performance of a reflow oven because of my experience with oven testing and participation in the IPC Reflow Oven Process Subcommittee. Some of the questions are basic, such as “Which oven should I purchase?” “Is this new oven as good as the older one?” or “Will it work with my boards or specific process requirements?” Other questions are more complicated: “Will this oven help me produce an acceptable profile with our heavy board?” or “Is this oven better than XYZ’s reflow oven?”

These questions got me thinking about establishing a guideline to compare the performance of reflow ovens. I use the word “compare” because oven evaluations can be different for each company due to specific needs and requirements. Years ago, I was involved with an IPC attempt to develop a reflow oven standard that included a proprietary test board, a proprietary thermal profiler and a defined thermal profile. The goal was to identify a basic way to “certify” that a reflow oven could produce an acceptable thermal profile, but it had little relevance to a company’s actual manufacturing requirements.

Proprietary test vehicles are not new. Several OEMs have developed various test vehicles with a varying number of possible connections. Each has its place, but in my experience they are only partially helpful in evaluating the performance of a reflow oven and are best for identifying if an oven thermal profile is changing over time.

Read Full Article

Tariff Tradeoffs

Buoyed by the US-China trade war, Mexico and Malaysia are making their move.

by Mike Buetow

On Jan. 6, 2023, the Wuxi Welnew Microelectronics plating plant in Wuxi, China, was decimated by a fire.

You’ve probably never heard of Welnew. It is a supplier of electroplating (Sn, SnBi, SnCu, L/F Ag, ZnNi, and so on) to a host of semiconductor manufacturers including Infineon, Vishay, Bosch, Osram, Onsemi, Renesas, Toshiba, and others. Welnew is critical to the supply chain: It claims a 60% market share for plating parts ranging from Mosfets, RF devices and LED drivers.

This happens in supply chains. If it’s not a typhoon, it’s a volcano. If it’s not a flood, it’s a fire. If it’s not an epidemic, it’s a pandemic. Lines and factories go down. Disruptions occur. Prices and lead times fluctuate, sometimes madly.

Read Full Article

Preventing Electrochemical Contamination at the Rework Station

The choice of flux plays a significant role.

by Timothy O’Neill

Although the rework bench plays a critical role in electronics manufacturing, engineers often overlook its cleanliness due to its lack of flashy machinery and perceived simplicity. Skilled hand solder operators proficiently completing their tasks can lull supervisors into a false sense of security, particularly since electrochemical contamination issues don’t manifest in this environment.

But in fact, as many as eight out of 10 contamination-related issues can be traced back to the rework bench. Here, we look at how these contaminations occur as well as how to prevent them by examining common products and tools in the rework bench environment.

PCD&F

Amphenol RF UWB Antennas

Ultra-wideband antennas can cover frequencies from 3.1 to 10.6GHz. Accurate location tracking, often within centimeters, and operate with low power consumption and provide high data transfer rates with the ability to penetrate walls and other obstacles. Are interference-resistant, for IoT and high-speed wireless applications such as smart home, smart agriculture, automotive, healthcare and telematics. Comply with international standards to ensure coexistence with other wireless systems and mitigate interference issues. Fit in consumer goods like wearables, mobile devices and small-scale industrial sensors.

Amphenol RF

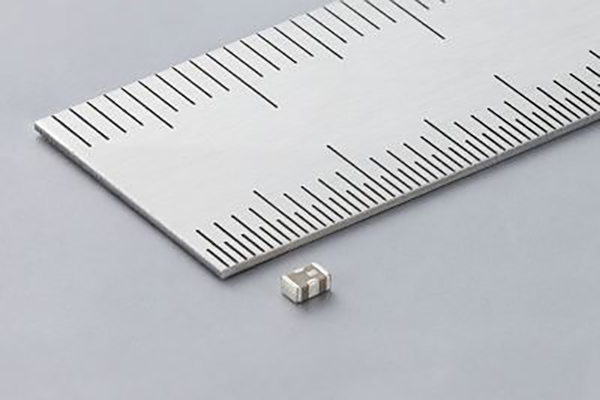

Murata L Cancel Transformer

L Cancel Transformer can neutralize the equivalent series inductance (ESL) of a capacitor, optimizing its noise-reducing capabilities. Minimizes noise within the frequency range of a few MHz to 1GHz by utilizing negative mutual inductance to reduce a noise-reducing capacitor’s ESL and increase the effectiveness of its operation, reducing the number of required capacitors. Uses non-magnetic ceramic multilayer technology to ensure stable negative inductance and low DC resistance (maximum 55mΩ) even in the presence of current variations, and is said to be suitable for a range of applications, including consumer, industrial and healthcare products. Is suitable for temperatures up to 125°C and can be used with stable negative inductance up to 3A. Measures 2 x 1.25 x 0.95mm and comes in tape-and-reel packing.

Murata Manufacturing

CA

Aven Cyclops 4K UHD Microscope

Cyclops 4K Ultra HD digital microscope is said to increase accuracy and productivity while easing eye strain and user fatigue. Offers an immersive viewing experience with 4K resolution for detail and clarity. Equipped with advanced optics and high-resolution imaging technology, provides magnification levels ranging from 13x to 140x, ensuring versatility for a range of inspection tasks. Seamlessly switch between HDMI and USB output modes for flexible viewing options and easy integration with existing imaging systems. Features user-friendly controls and a simple interface, for ease of operation and precise image capture. Connects to a computer or monitor via HDMI or USB for real-time viewing and image capture.

Aven

DDM Novastar NovaPlace

NovaPlace pick-and-place series features four models tailored to diverse needs. For use in various applications, from prototypes to short-run, high-mix manufacturing. Features user-friendly Windows-based operating software and easy programming with Gerber Input.

DDM Novastar

In Case You Missed It

Component Inspection

“Advancements in PCB Components Recognition Using WaferCaps: A Data Fusion and Deep Learning Approach”

Authors: Dmitrii Starodubov, et. al.

Abstract: As technology advances and becomes more complex, the demand for automated solutions to verify the quality and origin of components assembled on printed circuit boards (PCBs) is skyrocketing. This paper proposes an innovative approach to detecting and classifying microelectronic components with impressive accuracy and reliability, paving the way for a more efficient and safer electronics industry. The authors’ approach introduces significant advancements by integrating optical and x-ray imaging, overcoming the limitations of traditional methods that rely on a single imaging modality. This method uses a novel data fusion technique that enhances feature visibility and detectability across various component types, crucial for densely packed PCBs. By leveraging the novel capsule network, the authors’ system improves spatial hierarchy and dynamic routing capabilities, leading to robust and accurate classifications. The authors employ decision-level fusion across multiple classifiers trained on different representations – optical, x-ray, and fused images – enhancing accuracy by synergistically combining their predictive strengths. This comprehensive method directly addresses challenges surrounding concurrency, reliability, availability, and resolution in component identification. Through extensive experiments, the authors demonstrate that their approach not only significantly improves classification metrics but also enhances the learning and identification processes of PCB components, achieving a total accuracy of 95.2%. (Electronics, May 2024, https://doi.org/10.3390/electronics13101863)

Read full article