April 2024

This issue of PCD&F / CA brought to you by:

PCEA

PO BOX 807

AMESBURY, MA 01913

PCEA BOARD OF DIRECTORS

Stephen Chavez, CHAIRMAN

Justin Fleming, SECRETARY

Gary Ferrari, CHAIRMAN EMERITUS

MEMBERS

Michael Buetow

Tomas Chester

Douglas Dixon

Richard Hartley

Scott McCurdy

Anaya Vardya

Susy Webb

Eriko Yamato

pcea.net

PUBLICATION

- PCD&F/Circuits Assembly digital.pcea.net

WEBSITES

- PCD&F pcdandf.com

- Circuits Assembly circuitsassembly.com

NEWSLETTER

- PCB Update pcbupdate.com

PODCASTS

- PCB Chat pcbchat.com

EVENTS

- PCB West pcbwest.com

- PCB East pcbeast.com

EDUCATION

- PCB2Day pcb2day.com

- PCEA Training pceatraining.net

- Printed Circuit University printedcircuituniversity.com

AWARDS PROGRAMS

- Service Excellence Awards circuitsassembly.com

- NPI Awards circuitsassembly.com

pcdandf.com

DATABASE

- Directory of EMS Companies circuitsassembly.com

mike@pcea.net

frances@pcea.net

Peter Bigelow, Robert Boguski, John D. Borneman, John Burkhert, Jr., Stephen Chavez, Geoffrey Hazelett, Mark Finstad, Jake Kulp, Nick Koop, Alun Morgan, Susan Mucha, Greg Papandrew, Chrys Shea, Jan Vardaman, Gene Weiner

production@pcea.net

nathan@pcea.net

frances@pcea.net

will@pcea.net

frances@pcea.net

mike@pcea.net

jacqueline@pcea.net

PRINTED CIRCUIT DESIGN & FAB/CIRCUITS ASSEMBLY is distributed without charge to qualified subscribers. To subscribe, visit pcdandf.com or circuitsassembly.com and click on Subscribe.

For changes or cancellations to existing subscriptions: subscriptions@pcea.net

PRINTED CIRCUIT DESIGN & FAB/CIRCUITS ASSEMBLY is published monthly by Printed Circuit Engineering Association, Inc., PO Box 807 Amesbury, MA 01913. ISSN 1939-5442. GST 124513185/ Agreement #1419617.

© 2024, by Printed Circuit Engineering Association, Inc. All rights reserved. Reproduction of material appearing in PRINTED CIRCUIT DESIGN & FAB/CIRCUITS ASSEMBLY is forbidden without written permission.

Mega Mergers, Mega Headaches?

Are the days of the mega-merger over, or are we just about to experience a new wave?

A good case could be made for either. Which we should root for is another matter.

In Europe, GPV’s merger with its slightly larger competitor Enics in late 2022 created a $1.5 billion entity, sending the combined entity barreling up the CIRCUITS ASSEMBLY Top 50 list. Then consider Kontron and Katec, another rollup that now exceeds a billion dollars plus in sales. When it comes to M&A, Europe at least seems to have it “going on.”

Asia isn’t playing second fiddle. China Electronics Corp., one of the mainland’s largest entities, helps underwrite Nanjing Huadong Electronics, which bought top 15 EMS company TPV Technology in a reverse merger in 2021. TPV’s annual revenues are in the $7.5 billion range. That’s serious cabbage.

READ FULL ARTICLE

Cadence to Buy Beta CAE Systems for $1.2B

SAN JOSE, CA – Cadence Design Systems will buy Beta CAE Systems, a maker of software for analyzing car and jet engine designs, for $1.24 billion in cash and stock, the company announced.

Cadence said it will pay for the acquisition with around $744 million in cash and the rest in stock, and while it will take on debt to pay for the deal, it will pay that down with cash generated from operations.

Beta CAE’s software is used to analyze designs in automotive and aerospace industries, with customers such as Honda, General Motors and Lockheed Martin. Over the last several years, Cadence has expanded its system analysis portfolio to build out a comprehensive multiphysics platform including electromagnetics, electrothermal and computational fluid dynamics solutions, and with Beta CAE, Cadence will enter structural analysis, the largest system analysis segment, the company said.

READ FULL ARTICLERogers Announces New Facility in Mexico

CHANDLER, AZ – Rogers Corp. has signed a lease on a factory in Monterrey, Mexico, for advanced busbar manufacturing and engineering services.

The first phase of the new site is slated for completion in late 2024 and continues Rogers’ manufacturing footprint strategy of supporting customers in the regions where they operate, the company said.

“We are excited to expand our presence in North America to better support our global customers and the growing EV/HEV and renewable energy markets in this region. Our new factory in Monterrey will enable us to better support our customers with deeper technical collaboration, and local prototyping and supply capabilities that reduce lead times and improve service levels,” said Jeff Tsao, Advanced Electronic Solutions (AES) senior vice president and general manager.

TTM to Expand in Ohio

NORTH JACKSON, OH – TTM Technologies is planning an expansion at its PCB manufacturing plant here that will add 50 jobs to the existing 200 at the facility.

TTM Technologies’ investment will help produce essential components for many industries that have a large presence in the region, including aerospace, automotive, medical devices and industrial controls and automation, said Team NEO, an economic development organization for Northeast Ohio that worked with TTM to receive a tax credit for the expansion.

“TTM Technologies is pleased to bring this expansion of capability and opportunity for workforce growth to North Jackson, Ohio. The engagement by Team NEO, the Ohio Department of Development and JobsOhio to understand our extensive workforce training requirements was invaluable in our decision to grow this facility,” said Phil Titterton, COO, TTM Technologies. “This successful process has allowed all involved to develop a better understanding of the importance and criticality of US-made printed circuit boards.”

Ge-Shen Acquires Stakes in 3 EMS Firms

KUALA LUMPUR – Malaysian contract manufacturer Ge-Shen will purchase a 40% stake in EMS firm Local Assembly to expand its presence in electronics manufacturing.

The RM48 million ($10.2 million) transaction will be partially funded via proceeds from a private placement exercise, Ge-Shen said in an exchange filing.

“The board believes the acquisition will complement the existing business, enabling cross-marketing of products with diverse designs and specifications to a broader clientele. This will also drive synergistic value across the company through shared technology know-how,” Ge-Shen said.

READ FULL ARTICLECicor Acquires TT Electronics IoT Solutions

BRONSCHHOFEN, SWITZERLAND – Cicor Group in March announced its acquisition of TT Electronics IoT Solutions and its three production sites in the UK and China.

Cicor is paying GBP20.8 million ($26.5 million) on a cash and debt-free basis, subject to normal working capital adjustments. The transaction is expected to close in the first quarter of 2024, has received all required regulatory approvals and is subject to customary closing conditions.

The sites acquired from TT Electronics will combine with Cicor’s own Axis Electronics and STS Defence to create a new leader in the UK EMS market and make Cicor a European market leader in the production of high-end electronics for aerospace and defense applications, the company said in a release announcing the transaction.

READ FULL ARTICLECelestica to Expand TX Operations, Add 155 Jobs

RICHARDSON, TX – Celestica has signed an economic development deal here that will see the company redevelop a 30,000 sq. ft. office into a manufacturing facility and add 155 jobs.

The expanded facility will produce equipment based on AI learning systems for Celestica’s US-based customers across multiple industries.

As part of the agreement, Celestica must invest at least $5.5 million into converting the newly leased space, which is located near its current operations in Richardson, and the city government will pay a total of $250,000 as the company reaches certain milestones. Celestica must also create 155 new jobs with an average annual salary of $67,200 at the expanded facility.

READ FULL ARTICLEAltium Acquires Valispace Software Platform

SAN DIEGO – Altium has acquired Valispace, a systems and requirements engineering software platform, for $15.6 million.

Valispace’s capabilities in Systems and Requirements Engineering will complement the Altium 365 cloud platform for product and electronics design, the company said in a release announcing the acquisition, and together the solutions connect electronics hardware design and development with systems engineering, encompassing everything from initial requirements definition to PCB design and verification.

Altium’s experience in developing tools for thousands of engineers with essential electronics design software will ensure that the Valispace team can continue to bring the best collaborative and AI-assisted systems and requirements experience to engineers, the company said.

READ FULL ARTICLEScanfil Updates Growth Strategy, Outlines New Business Segments

OULU, FINLAND – Scanfil in March announced a new growth strategy that will seek acquisitions, as well as a division into three new business segments.

Over the past three years, the company has pushed for organic growth, but it is now shifting to seek a balance between organic and inorganic growth, and grow through potential acquisitions that would complement its customer base and factory network in Asia (outside of China), North America and Eastern Central Europe.

The company will also work to accelerate its organic growth by moving to three business segments: Industrial, Energy & Cleantech and Medtech & Life Science. Industrial was formed by combining its previous three segments: Advance Consumer Applications, Automation & Safety and Communications.

READ FULL ARTICLEDoD Awards $12M to Ensign-Bickford to Expand PCBA Production

WASHINGTON – Ensign-Bickford Aerospace & Defense received $11.7 million from the Department of Defense to expand PCBA production at its Simsbury, CT, location.

The company received the award through the DoD’s Defense Production Act Investment (DPAI) Program, and will use the funds to increase its existing capacity and manufacturing processes to reduce cost and accelerate PCBA production for use in hypersonic weapons.

“This effort is a key component of the DoD’s strategy to accelerate the development and fielding of hypersonic systems and deliver cutting-edge capabilities to our armed forces,” said Dr. Laura Taylor-Kale, assistant secretary of defense for industrial base policy. “This award also represents another investment in domestic manufacturing in accordance with the National Defense Industrial Strategy to help build a modernized defense industrial ecosystem.”

JEDEC Publishes GDDR7 Graphics Memory Standard

ARLINGTON, VA – JEDEC has published JESD239 Graphics Double Data Rate (GDDR7) SGRAM, which offers double the bandwidth over GDDR6, reaching up to 192GB/s per device, and is poised to meet the escalating demand for more memory bandwidth in graphics, gaming, compute, networking and AI applications.

JESD239 GDDR7 is the first JEDEC standard DRAM to use the Pulse Amplitude Modulation (PAM) interface for high frequency operations. Its PAM3 interface improves the signal to noise ratio (SNR) for high frequency operation while enhancing energy efficiency. By using three levels (+1, 0, -1) to transmit 3 bits over 2-cycles versus the traditional NRZ (non-return-to-zero) interface transmitting 2 bits over 2-cycles, PAM3 offers higher data transmission rate per cycle resulting in improved performance.

Additional advanced features include:

READ FULL ARTICLEJinlu Electronics Begins $320M Expansion Project

QINGYUAN, CHINA – Chinese PCB fabricator Jinlu Electronics has begun construction on a 2.3 billion yuan ($320 million) expansion project that will add an additional 3 million sq. m. of production capacity for multi-layer rigid boards and high-density interconnect boards.

The company purchased approximately 63 acres adjacent to the company’s existing factory in the Guangdong Qingyuan High-tech Industrial Development Zone, and plans to build two factories, a wastewater station and chemical warehouse, and worker dorms.

Jinlu said the project will be constructed in three phases, with construction and production at the same time. Over the planned 60 months for construction, the first phase construction period (including preliminary planning) is expected to be 18 months, and is expected to be put into operation in July this year, with a planned production capacity of 1.2 million sq. m.

READ FULL ARTICLEToppan Plans Singapore Chip Package Substrate Plant

TOKYO – Toppan Holdings will build a semiconductor package substrate plant in Singapore, with plans to begin operations at the end of 2026.

The company said it anticipates the factory to create 200 jobs, with a capacity that will likely increase in line with demand and a total investment of 100 billion yen with the planned growth. Toppan will bear the majority of the initial 50 billion yen investment of the plant, while capacity expansions later could receive financial support from the company’s main customer, Broadcom, the company said.

Toppan currently produces package substrates only at its plant in central Japan’s Niigata prefecture. The planned Singapore factory will be near many back-end processing contractors that handle semiconductor assembly and testing in Malaysia and Taiwan. The company looks to boost its overall substrate production capacity 150% by fiscal 2027 compared with fiscal 2022 by expanding the Niigata facility and opening new facilities.

Apple Acquires AI Inspection OEM

WATERLOO, ON – Apple has acquired artificial intelligence startup DarwinAI as it looks to add technology for a push into generative AI, Bloomberg reported. Financial and other terms were not disclosed.

Dozens of DarwinAI’s employees have joined Apple’s artificial intelligence division, including Alexander Wong, an AI researcher at the University of Waterloo who helped build the business, who joined Apple as a director in its AI group, according to the report. Apple is not expected to maintain the assembly inspection equipment that DarwinAI developed, however.

DarwinAI is a Canadian startup that has developed AI technology for visual inspection of components, and it also has a stated goal of making AI systems smaller and faster.

READ FULL ARTICLEKemppi Forming Electronics-Focused Subsidiary

LAHTI, FINLAND – Kemppi Group is splitting its electronics business into its own company, Kemptron, to strengthen its position in the electronics industry.

The newly formed company will manufacture circuit boards, subassemblies, modules, transformers and chokes, Kemppi said, and will operate as a subsidiary of the group.

“Kemptron Oy will strengthen the positioning of Kemppi Group’s electronics business and enable business growth,” said Jari Takala, general manager of Lahti operations, Kemptron. The company will take into account the specific needs of its customer industries. Kemptron Oy will provide power electronics components for Kemppi Group companies’ products.”

READ FULL ARTICLEKatek to Delist Following Agreement with Kontron

MUNICH – Katek will enter into a delisting agreement with Kontron following Kontron’s acquisition of a controlling stake in the company earlier this year.

In January, Kontron announced the acquisition of 59.4% of Katek’s shares by its subsidiary, Kontron Acquisition, which is obliged to make a mandatory offer to the shareholders of Katek SE in the coming weeks in accordance with the provisions of the German Securities Acquisition and Takeover Act.

Katek’s board has decided that the delisting is in the interests of the company since the stock market listing has lost its significance, and the delisting is therefore advantageous from a strategic and financial perspective, the company said in a release.

READ FULL ARTICLEVDL to Build Vietnam Manufacturing Facility

EINDHOVEN, NETHERLANDS – VDL is planning to build a new manufacturing facility in Vietnam, with an anticipated opening in early 2025.

The company said its global customers have asked for more local production for local markets, and the new facility is part of a larger plan to invest in Europe, America and Asia. VDL Emerging Technology Group, its high-tech cluster, also has Asian locations in Singapore and Suzhou, China.

“Being able to deliver anywhere is a major advantage for VDL’s existing and new customers,” the company said in a release.

VDL said 60 employees will initially work at the facility when it opens, which is expected to be at the end of the first quarter or beginning of the second quarter of 2025.

Mycronic Makes Optical Fab Acquisition

TÄBY, SWEDEN – Mycronic’s Global Technologies division signed an agreement in March to acquire Vanguard Automation, a German company that has developed a technology and automated equipment for 3-D microfabrication of optical interconnects.

Karlsruhe, Germany-based Vanguard Automation’s area of expertise complements the Mycronic’s die bonding business line and enables the offering of a wider range of die bonding and optical packaging-related solutions, Mycronic said.

“Joining the Mycronic group marks a pivotal milestone for Vanguard Automation in its mission to deploy 3-D nano-printing solutions in volume production for cutting-edge photonic devices,” said Vanguard Automation CEO Thorsten Mayer. “We are looking forward to joining forces with Mycronic’s Global Technologies division, enriching the offerings for our global customer base.”

“Megatrends such as AI, cloud computing and augmented reality are boosting demand for computational power, leading to larger, more energy-intensive data centers,” said Magnus Marthinsson, senior VP of Global Technologies, Mycronic. “Vanguard Automation’s unique solutions will help speed up optical interconnects and cut energy consumption at the same time.”

READ FULL ARTICLEPCD&F

Alpha Circuit installed a Gardien G90L flying probe.

Bomin Electronics is expanding its annual PCB production capacity by 1.72 million sq. m., increasing its shipment of high-count multilayer boards, HDI boards and IC carrier boards.

Cadence Design Systems is collaborating with Arm to deliver a chiplet-based reference design and software development platform.

Calumet Electronics received an Industrial Facility Tax Certificate to assist in the building of its $51 million advanced substrate factory in Michigan.

PCB distributor DirectPCB opened an office in Barcelona, Spain.

Read Full ArticleCA

Absolute EMS installed its second Hanwha Techwin TRNeF103 reflow oven.

AIM Solder named Cornerstone Technical Marketing sales representative in California and Nevada and Solder Connection representative in Ireland.

CE3S opened a distribution center in Orlando, Florida.

Cutera will pay $19.5 million in a settlement deal to Jabil after it decided not to renew their manufacturing service deal, according to a filing with the US Securities and Exchange Commission.

Emerald Technologies purchased an Ersa Versaflow 4/55 selective soldering machine for its Saline, MI, location.

Read Full Article

PCD&F

AT&S named Rafael Padilla senior manager, business development.

Incap appointed David Spehar to its management team.

PCB Technologies announced David Warner as account manager, East Coast.

Uyemura promoted Russ Schwartz to project engineer and appointed Steve Medd support engineer.

Ventec appointed Leigh Eastwood technical sales engineer.

CA

AIM Solder named Chris Matthews business development manager.

ALL Circuits named Stephane Klajzyngier group strategy and development director.

BAE Systems named Ian Linn operations manager.

ECD hired Nicholas Chase as senior software engineer and Rahul Bilakanti as manufacturing engineer.

Intraratio named Ken Reilich senior vice president of worldwide sales and marketing.

Read full article

See us at APEX

Booth #4309

PCEA Training Announces June and September PCB Design Classes

PEACHTREE CITY, GA – PCEA Training is offering a pair of five-day training classes in June and September for printed circuit engineers, layout professionals, and other individuals currently serving in the design engineering industry or seeking to get into it. The classes include an optional certification exam recognized by the Printed Circuit Engineering Association (PCEA).

The dates of the classes:

- Class 1: June 14, 17, 21, 24, 28

- Class 2: September 16, 17, 18, 19, 20

These instructor-led classes cover the gamut of printed circuit design engineering, from layout, place and route to specifications and materials to manufacturing methods. Schematic capture, signal integrity and EMI/EMC are also part of the comprehensive program.

Read Full ArticleDenver. Those interested in attending a meeting in the Denver area on May 13 should contact Mike Buetow (mike@pcea.net). The meeting will feature a talk on PCB design and time for networking.

New England. The chapter will have its kickoff meeting on May 2 on the campus of the University of Massachusetts-Lowell. Featured speakers are Gopu Achath of EMA Design Automation on supply chain-driven circuit design and Paul Yang of Jove PCB on embedded inductors. Contact Mike Buetow at mike@pcea.net for details.

Portland. The next chapter meeting is scheduled for April 18 at 12 pm. Contact Stephan Schmidt for details (stschmidt@outlook.com).

Thailand Leading Way as Industry Alternative to China

TAIPEI – Taiwan’s PCB industry continues to expand its factories in Thailand and Vietnam to strengthen the resilience of the global PCB supply chain, and representatives of the Taiwanese and Thai governments are actively negotiating for assistance to Taiwanese factories, says the Taiwan Printed Circuit Association.

According to a client survey conducted by Goldman Sachs Group in early 2024, 54% of respondents see geopolitics as the main risk to the current market and the global economy, while the threat of inflation has eased. In addition to cost-effectiveness and market operations, geopolitics has become an important consideration in international supply chain strategic planning. Against this backdrop, Southeast Asia has become a direct beneficiary of the global PCB and electronics supply chain.

In addition to the advantages of abundant labor and relatively low labor costs, the geopolitical risks in Southeast Asia are also limited. Amid the current international tensions, the region has become a popular choice for enterprises seeking an alternate production base, which is conducive to promoting the development of the local PCB industry. Among them, Thailand has a leading competitiveness in the region by virtue of its relatively mature PCB and downstream electronics industry. In 2023, Thailand’s PCB local production output will account for about 3.8% of the world’s total, and it is expected to grow to 4.7% in 2025 as the world’s major PCB manufacturers continue to deploy locally. (more)

Hot Takes

Printed circuit board assembly production by EMS companies achieved record revenues of 57.3 billion euros in 2023, with EMS outsourcing representing 43% of the total available market of Europe’s PCB assembly. (in4ma)

The US lacks the capacity – even with the 109 fabs planned to come into operation by 2026 – to see its semiconductor industry become a $1 trillion market by 2030. (SEMI)

Global PC shipments are predicted to reach 265.5 million units in 2024, up 2% from the prior year. (IDC) (more)

The Point of Pride

Returning to a focus on soft skills will help industry find responsible employees.

For well over a decade, the number one question, complaint and concern I hear from businesspersons, regardless of industry or company size is: “Where is industry – any and every industry – going to find all the people necessary to actually build stuff?” And yet despite this serious workforce void, businesses continue to plan on a combination of reshoring product from distant lands or growing organically – which requires expanding their workforce. But how can you expand your manufacturing when the most critical ingredient – employees – is nowhere to be found?

Academia, from the earliest contact in elementary school to high school and right through university, has become misaligned with the real-world skills and education needed for a balanced and thriving economy. Yes, society needs doctors, lawyers, engineers and other more academically focused professions, but society also needs people with the interest and skill to touch and build product. In addition, there are real skills, education and training that together enable a worker to operate the complex and simple machinery and processes that successfully produce a multitude of technologically advanced, viable and sought after products. Maybe it is time to recalibrate our focus to some of the traits and skills that lead to success regardless of profession but appear to be currently missing in the workforce.

The first is promoting, developing and rewarding something called work ethic. From elementary through graduate school, teachers should instill in students that while the grade is important, it’s how you work toward getting a grade that is the arbiter of future success. Acknowledging the effort made even if by way of saying “well done” to someone who is giving a task everything they have, even when they fall short of an “A+.” Being motivated promotes a strong work ethic. In my career, I have worked with many “C+” people who through hard work and dedication – work ethic – have outperformed their classroom “A+” peers. How? They simply worked harder, took the task at hand seriously, and continually strived to improve. I fear academia is often too quick to stress the grade when the more important life skill is developing and maintaining a strong work ethic.

Read Full Article

The 80/20 Rule

Don’t be afraid to drop bad fit customers.

Since tax season is upon us, I recently had a chat with my CPA. She is co-owner of one of the largest accounting firms in my area and I’ve done business with her for over two decades, so we discuss business strategy in addition to going over the numbers. This year, she mentioned they were planning to rationalize their customer base, eliminating those who tended to provide incomplete records right before critical deadlines. She saw these clients as problematic to her business for two reasons: they overloaded resources and their behavior increased the probability her team would make a mistake.

There is a parallel in the electronics manufacturing services (EMS) industry. Ask any longtime industry CEO and they will say 80% of their issues come from 20% of their customer base. Why do EMS companies keep bad fit customers? There are a number of reasons:

Read Full Article

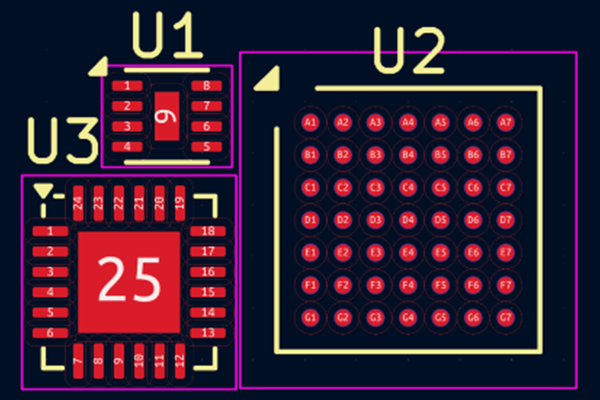

Designing for PCB Assembly

What’s best for your design may not be what’s best for assembly.

Printed circuit board assemblies animate a collection of components designed to do something useful. Joining those components on a board that completes the connections with a circuit pattern is the best solution we have to create modern electronic devices. The performance and reliability of the device is largely determined by interconnections on the PCB assembly.

The placement itself is a function of the signal connectivity on a local scale and voltage domains on a macro scale. More chips equal more voltage domains. Each IC requires dedicated support consisting of some or all of the following:

- Passive components that do the grunt work of supplying and filtering power

- External clocks for optimizing data flow

- Local power supplies

- Test points, connectors, etc.

- Wherever the I/O pins take you in terms of neighboring components.

A Journey in Rigid-Flex Design

Overcoming the challenges of rigid-flex designs can be incredibly rewarding.

As technology continues to advance, the demand for smaller, lighter and more efficient electronic devices is ever increasing. This demand has led to the emergence of rigid-flex PCBs, a revolutionary technology that combines the benefits of rigid and flexible circuits into a single solution.

As a principal PCB designer with several decades of experience in designing a wide spectrum of PCB technologies, I’ve had the privilege of delving deep into the world of rigid-flex PCB design. This month I’ll share insights and experiences from my journey within this fascinating technology.

How Do We Power 5G Networks?

5G has great potential, but brings power challenges at the infrastructure and board levels.

5G network capacity is predicted to increase as much as 1000-fold by 2030. That’s a stunning increase that can be attributed to effects such as our digital lifestyles and digital business transformation. Clearly, our dependence on online services that are available anytime, anywhere and at full speed shows no sign of abating. The effect on global energy demand could be even more stunning. The information & communications technology (ICT) industry currently consumes about 4% of the world’s electricity, and this could increase to an amazing 20% with the growth of 5G networks. In absolute terms, that’s equivalent to 150 quadrillion BTU per year.

Of course, 5G is huge, in scope as well as deployment. It covers low frequency bands, up to about 1GHz, although the main benefits of 5G are its ability to carry richer services that by their nature require faster data rates. These will push the limits of Frequency Range 1 (FR1) as defined by 5G standards, up to 6GHz in the FR1 range, and even higher in FR2 that extends into the millimeter-wave bands at 60-70GHz and even beyond. While services in the FR1 bands can support data rates of about 1-2Gbit/s, the higher bands are needed to support multi-gigabit data rates and latency of less than a few milliseconds.

At the highest frequencies, however, signaling range is considerably reduced. Each cell can only cover a small area. Weather conditions and other atmospheric effects can also affect range and the performance of the air interface. Many cells are needed to extend coverage, which will tend to restrict the fastest, most intuitive and high-value services to metropolitan areas. So, although we can expect to download at speeds of 10Gbit/s and faster – enough to allow downloading a complete high-definition movie in a few seconds – network deployment costs are high and extending coverage to reach rural areas is challenging.

Read Full Article

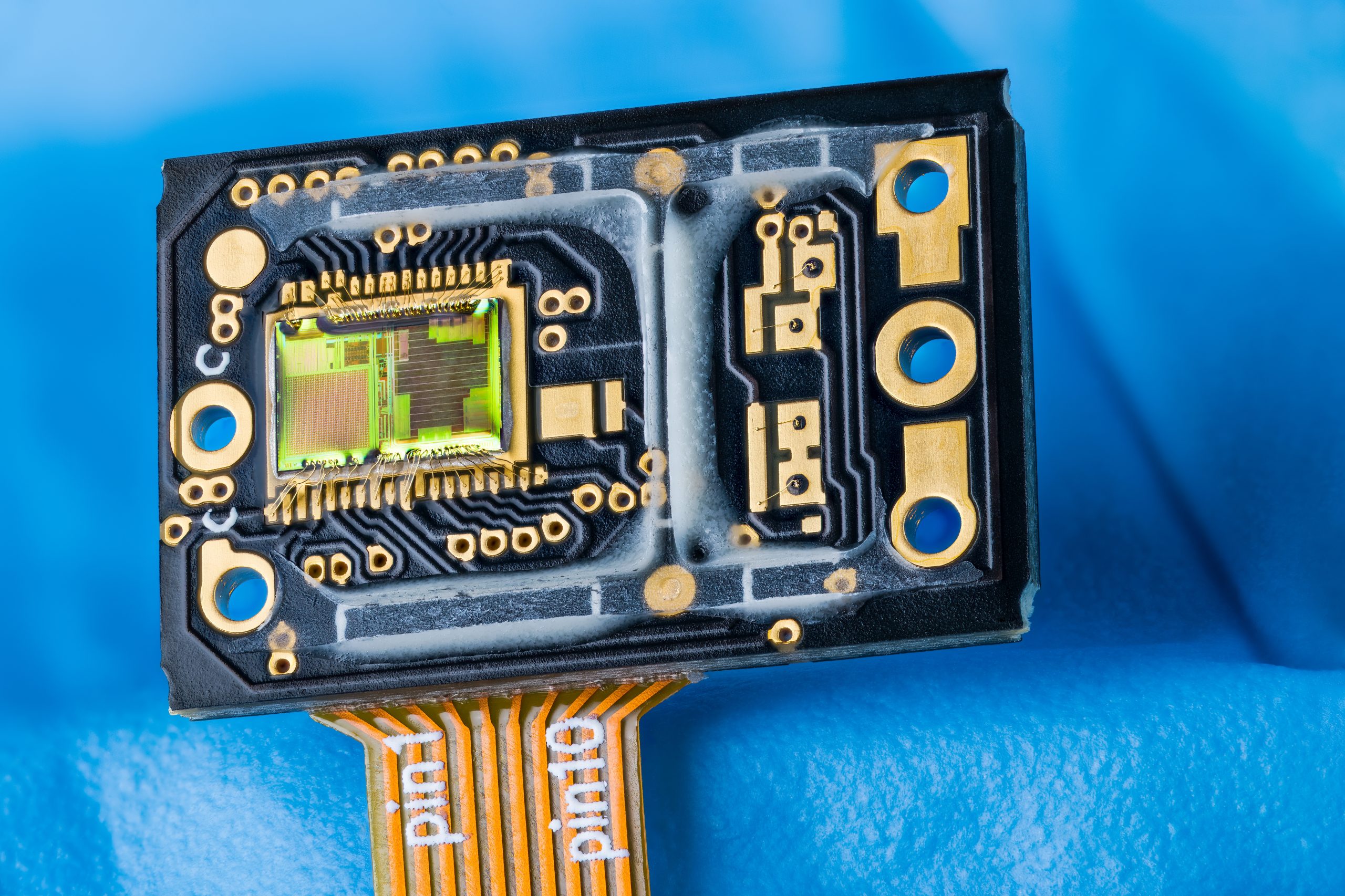

Tear Resistance in Flexible Circuits

Proper design and handling can minimize the risk of rips.

I have a potential new application for a flexible circuit for use in an inspection device. The flexible circuit will see some light pulling and tugging forces when extracted. Should I be concerned the circuit may be prone to tearing? If so, are there different materials that can be used that will not tear?

The short answer is yes; flex circuits can tear if not properly designed or handled. You did not mention the number of layers or the thickness, so I will assume that your application is only one or two layers and is on the thin side. As the layer count goes up, so does the thickness, and therefore the strength and tear resistance. Once a flex is four-plus layers with standard thickness materials, it should be very durable, and tearing should not be a concern if the extraction does not generate extreme shearing forces.

Virtually all flex circuits use polyimide film as the primary insulator. Polyimide film has lots of great electrical and mechanical qualities, but tear resistance is not one of them. In static applications there is seldom an issue, but if there are multiple flexing cycles during service, preemptive steps mut be taken in the design to guard against tears. The key is ensuring that a tear does not start, because once it does, it tends to propagate.

Read Full Article

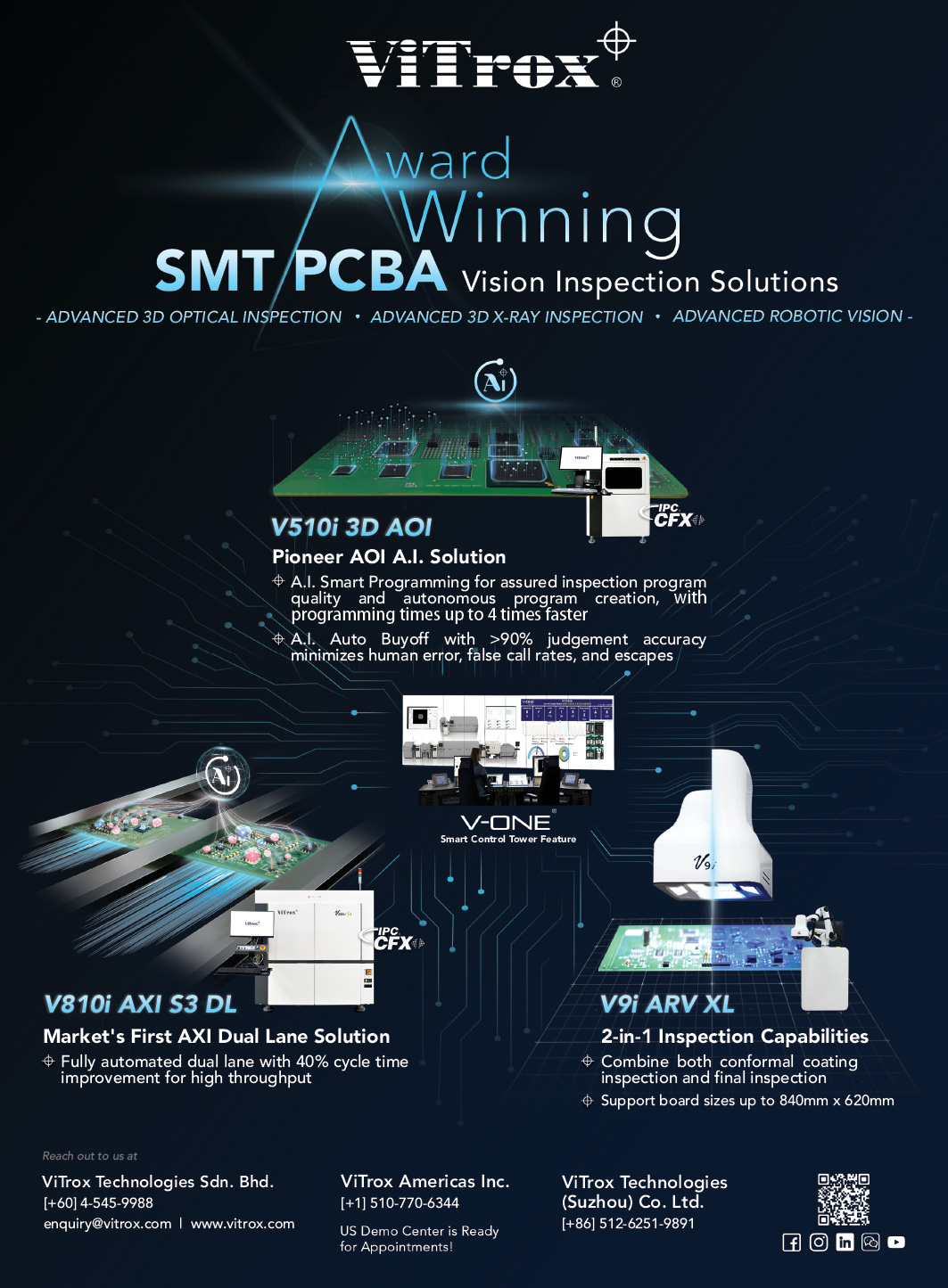

CIRCUITS ASSEMBLY Announces 2024 NPI Award Winners

PEACHTREE CITY, GA – CIRCUITS ASSEMBLY in March announced the 2024 New Product Introduction Award winners for electronics assembly equipment, materials and software.

The 17th annual NPI Awards recognized leading new products during the past 12 months. An independent panel of practicing industry engineers selected the recipients.

The winners are:

Read Full Article

Thermal Vias are Ineffective. Here’s Why.

Adding thermal vias can take up valuable board space with little benefit.

by Douglas G. Brooks, Ph.D. and Dr. Johannes Adam

We have developed several articles and publications in the past questioning the value of thermal vias.1 Here is our definitive conclusion, and why.

Thermal vias are non-current-carrying vias between two layers provided for the purpose of permitting heat to conduct from one layer in a PCB to another. The idea is to lower the temperature of the heated surface compared to another, lower temperature surface. In a typical application, the heated surface might be a pad underneath a heated component. The opposite surface might be another pad or plane further down in the PCB structure. Someone untrained in heat transfer might suggest using thermal vias without an opposite copper surface, but we will show that such an approach is totally ineffective.

Simulation Model

We used the simulation tool TRM2 to simulate several different combinations of thermal vias and configurations. The simulations consisted of:

Read Full Article

Connecting the Industry, from Boards to Assemblies

HDP is embarking on new rounds of evaluations of laminates and lead-free solders.

by Mike Buetow

The High-Density Packaging User Group, the nonprofit consortium of electronics manufacturers and suppliers that collaborate on various technical problems in order to reduce cost and time to market, has nearly 25 projects underway, several of which are due to be completed this year.

We spoke in March with Madan Jagernauth, marketing director and project facilitator of HDP, about its current research on lead-free solder alloys, its recent conference Best Papers, and whether the consortium members are ready to tackle artificial intelligence.

The following has been lightly edited for grammar and clarity.

Mike Buetow: It seems like 2024 is something of a transition year for HDP. You had your 30-year anniversary last year. You completed eight projects and you have 18 more now in the implementation phase. Let’s start with the year just ended. As part of your anniversary HDP prepared four special retrospective reports. Can you summarize them and explain why HDP felt it was important to look backward as well as forward?

Read Full Article

Exploring the Impact of AI

A special panel discusses the growth of AI tools and its possible effects on the industry.

by Tyler Hanes

“Will AI take my job?”

That’s the question on the mind of many around the world today – including electronics engineers and PCB design engineers – and was one of several questions considered during an online panel hosted by PCEA in March.

A group of panelists with notable AI experience – Circuit Mind’s Tomide Adesanmi, Cadence Design Systems’ Taylor Hogan, Zuken’s Kyle Miller, Luminovo’s Sebastian Schaal and Siemens Digital Industries’ David Wiens – gathered to share predictions for the future of AI in the electronics supply chain and answer questions from an audience of industry professionals.

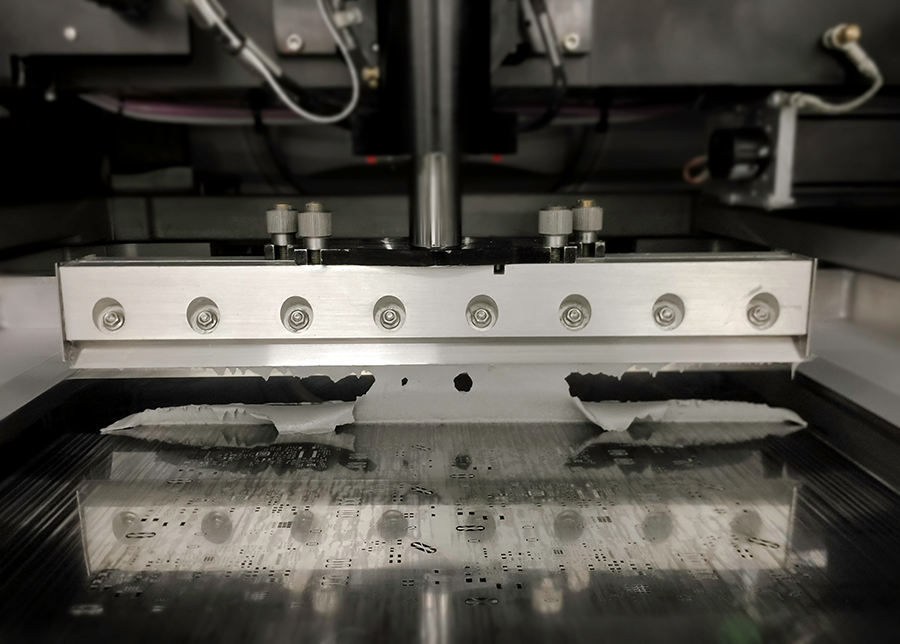

Preserving Solder Paste Integrity

A closer look at mixing methods and automated mixers.

by Gayle Towell

While automation in manufacturing brings efficiency and consistency, the use of automated solder paste mixers is a topic of debate, with significant concerns over their impact on the paste’s properties. This comprehensive analysis delves into why many industry experts advise caution.

Solder paste is not just a blend of materials; it’s a finely tuned compound where each element plays a specific role. The balance between solder powder and flux is crucial, as it determines the paste’s behavior during the printing process and affects the quality and reliability of solder joints. Certain properties of the paste – its viscosity, rheology and thixotropy – fundamentally determine how well it will perform and can be significantly affected by how the paste is handled.

PCD&F

KiCad 8.0 ECAD

KiCad 8.0 features hundreds of bug fixes, performance improvements and other smaller changes since KiCad 7. Includes improvements to the official KiCad libraries, expanded support for importing data from other tools, new possibilities for data export, improvements to the command-line interface, improvements to documentation and other smaller changes. Also features numerous improvements to schematics and symbols, including new UI panels for properties, net navigation and search, as well as a new BOM exporter. Simulation improvements include a simulator UI overhaul and new features, and PCB and footprints improvements include multiple footprint dragging, interactive length tuning patterns, a 3-D viewer UI overhaul and other smaller changes.

KiCad

Kyocera AVX 9159-600 Series Connectors

9159-600 dual-row inverted through-board card edge connectors feature staggered contacts that enable four to 12 positions. Features a BeCu contact system that provides full 2.5A per contact current rating and low-profile (2.85mm above-board) through-board design supports applications with minimal height constraints on the mating side of PCB and doesn’t interfere with LEDs. Staggered contact configuration prevents shorting and contact damage when inserting and removing mating PCBs, and is approved to UL1977 safety standards. Is for 1.6mm-thick mating PCBs with gold-plated pads and rated for 2.5A per contact, 300VAC, 10 mating cycles, and operating temperatures extending from -40° to +125°C. Features white, glass-filled, high-temperature, UL94 V-0 nylon insulators equipped with 4, 6, 8, 10, or 12 contacts, gold plating on the nose, and lead-free matte tin plating on the tails.

Kyocera AVX

CA

Delo Medical-Grade Adhesive

MONOPOX MG372 medical-grade adhesive is for assembly of biosensors, including ECG/EKG electrodes. Is one-component, solvent-free and humidity-resistant, and features a Young’s modulus of 160MPa. Features a glass transition temperature of -52°C and takes 10 minutes to fully cure at 90°C. Also features a viscosity of 30,000mPa·s and can be easily applied via needle dispensing.

Delo Industrial Adhesives

Göpel MultiEyeS Plus AOI

MultiEyeS Plus AOI now features an intelligent assistance function for THT placement. Features a 47MP image acquisition unit equipped with a flexible LED lighting system to provide very high image quality and detail resolution with an inspection area of up to 650 x 550mm. Verifies presence, position and color of THT components, reads labeled or laser-edged 2-D codes and barcodes, and recognizes text. Integrates a powerful laser projection into the AOI module for the assistance function, which makes it possible to intuitively support manual placement by displaying placement information directly in operator’s field of vision, and displays faults detected during placement directly on the PCB.

Göpel Electronic

In Case You Missed It

Electromagnetic Compatibility

“High-Frequency Modelling of Electrical Machines for EMC Analysis”

Authors: Yerai Moreno, et. al.

Abstract: The trend toward electrification in mobility has led to increased use of silicon carbide (SiC) semiconductors. These semiconductors are more efficient but also present challenges related to electromagnetic interference (EMI) due to their higher voltage derivatives. This paper introduces a new high-frequency impedance model for electrical machines. The proposed model distinguishes itself from existing approaches by being entirely derived from finite element method (FEM) simulations, which include capacitances in the magnetic simulation. This approach achieves a balance between computational efficiency and high accuracy across the entire frequency spectrum, ranging from 100Hz to 50MHz. The model provides valuable insights during the design phase and was rigorously validated using data from 28 samples of an industrial machine. (Electronics, February 2024, https://doi.org/10.3390/electronics13040787)

Read full article