March 2024

This issue of PCD&F / CA brought to you by:

PCEA

PO BOX 807

AMESBURY, MA 01913

PCEA BOARD OF DIRECTORS

Stephen Chavez, CHAIRMAN

Justin Fleming, SECRETARY

Gary Ferrari, CHAIRMAN EMERITUS

MEMBERS

Michael Buetow

Tomas Chester

Douglas Dixon

Richard Hartley

Scott McCurdy

Anaya Vardya

Susy Webb

Eriko Yamato

pcea.net

PUBLICATION

- PCD&F/Circuits Assembly digital.pcea.net

WEBSITES

- PCD&F pcdandf.com

- Circuits Assembly circuitsassembly.com

NEWSLETTER

- PCB Update pcbupdate.com

PODCASTS

- PCB Chat pcbchat.com

EVENTS

- PCB West pcbwest.com

- PCB East pcbeast.com

EDUCATION

- PCB2Day pcb2day.com

- PCEA Training pceatraining.net

- Printed Circuit University printedcircuituniversity.com

AWARDS PROGRAMS

- Service Excellence Awards circuitsassembly.com

- NPI Awards circuitsassembly.com

pcdandf.com

DATABASE

- Directory of EMS Companies circuitsassembly.com

mike@pcea.net

frances@pcea.net

Peter Bigelow, Robert Boguski, John D. Borneman, John Burkhert, Jr., Stephen Chavez, Geoffrey Hazelett, Mark Finstad, Jake Kulp, Nick Koop, Alun Morgan, Susan Mucha, Greg Papandrew, Chrys Shea, Jan Vardaman, Gene Weiner

production@pcea.net

nathan@pcea.net

frances@pcea.net

will@pcea.net

frances@pcea.net

mike@pcea.net

jacqueline@pcea.net

PRINTED CIRCUIT DESIGN & FAB/CIRCUITS ASSEMBLY is distributed without charge to qualified subscribers. To subscribe, visit pcdandf.com or circuitsassembly.com and click on Subscribe.

For changes or cancellations to existing subscriptions: subscriptions@pcea.net

PRINTED CIRCUIT DESIGN & FAB/CIRCUITS ASSEMBLY is published monthly by Printed Circuit Engineering Association, Inc., PO Box 807 Amesbury, MA 01913. ISSN 1939-5442. GST 124513185/ Agreement #1419617.

© 2024, by Printed Circuit Engineering Association, Inc. All rights reserved. Reproduction of material appearing in PRINTED CIRCUIT DESIGN & FAB/CIRCUITS ASSEMBLY is forbidden without written permission.

What’s the Deal with the Altium Deal?

The masses are atwitter over the recently announced Renesas acquisition of Altium, and for good reason. The $5.9 billion price tag is some real coin.

What’s less clear to almost everyone outside the two companies, however, is the underlying strategy and how the merged entity will look going forward.

In announcing the acquisition, Renesas chief executive Hidetoshi Shibata called it “an important first step into our long-term future.” But what is that future?

READ FULL ARTICLERenesas to Buy Altium for $5.9B

TOKYO – Renesas Electronics will acquire Altium for A$9.1 billion (US$5.9 billion) in cash, subject to a number of conditions, the companies announced in mid-February. The deal has an enterprise value of A$8.8 billion ($5.7 billion).

The transaction has been unanimously approved by the boards of directors of both companies and is expected to close in the second half of 2024. Completion of the transaction is subject to approval by Altium shareholders, Australian court approval as well as regulatory approvals and other customary closing conditions.

Renesas plans to finance the transaction with bank loans and cash on hand and the transaction is not subject to any financing conditions. Altium will continue to be led by its CEO, Aram Mirkazemi, as a wholly owned subsidiary of Renesas.

READ FULL ARTICLETata Gets Green Light for Wistron iPhone Unit Acquisition

MUMBAI, INDIA – Tata Group received approval from India’s Competition Commission to acquire Wistron’s Indian iPhone production unit, paving the way for Tata to become India’s first homegrown iPhone maker.

Tata and Wistron agreed to the $125 million sale of Wistron’s iPhone factory near Bengaluru in October after Wistron sought to diversify its business beyond iPhone manufacturing into areas such as servers. The company also sold its iPhone production business in China to a competitor in 2020.

Tata was in talks for more than a year to take over the plant as it seeks to forge closer ties with Apple. The deal also advances India’s efforts to create local contenders to challenge China’s dominance in electronics.

EOS/ESD Association Releases Technology Roadmap

ROME, NY – The EOS/ESD Association released its Technology Roadmap, which presents estimated threshold changes in electrostatic discharge (ESD) and the potential impact on ESD control practices through 2030.

In an effort to keep abreast of the evolving electronics industry, the document is updated annually by EOS/ESD Association.

The first section of the roadmap provides estimates of future electrostatic discharge (ESD) thresholds of semiconductor devices and the potential impact on ESD control practices. These levels are strongly technology- and design-dependent and need to be periodically revised in the context of advances in the electronics industry. The second section contains information on device testing trends and characterization from the ESDA and ESDA/Joint Electron Device Engineering Council (Jedec) teams working on these methods. The roadmap also includes an outlook on important trends in the semiconductor industry looking toward 2030 and closes with a section on electronic design, an important contributor to reliable and robust ESD and latch-up design.

READ FULL ARTICLEUK-Based EC Electronics Acquires Liad Electronics

BASINGSTOKE, UK – EC Electronics has acquired Dutch EMS provider Liad Electronics, growing EC’s presence in mainland Europe and expanding its manufacturing capacity.

Liad Electronics Breda specializes in printed circuit board assemblies, and the company’s operations in the Netherlands will continue to be overseen by Rick Meesters, who will be reinvesting in the group and joining the board, said EC Electronics.

“We are very excited about Liad Electronics joining the EC Group and working with the incredibly experienced team there,” said Phil Simmonds, CEO, EC Electronics. “Liad will now be the foundation for the next stage of our growth plans in mainland Europe and a key part of the future success of the group.”

“The additional services offered by EC will allow us to significantly improve our position and provide extra support to existing relationships,” said Meesters.

Lean Stream, Fuji, Koh Young Unite for Collaborative Workspace

ATLANTA – Lean Stream, Fuji America and Koh Young America have partnered to launch a collaborative workspace in Fremont, CA.

Recognizing the importance of skilled professionals in driving industry progress, the workspace will host comprehensive training programs to empower individuals with the knowledge and skills needed to navigate the evolving landscape of electronics manufacturing. Attendees will explore interconnected systems, artificial intelligence and data analytics that enhance decision-making and streamline production. The goal is to empower manufacturers to embrace Industry 4.0 standards, fostering a new era of efficiency and competitiveness.

“The grand opening event was not just a ribbon-cutting ceremony; it was celebration of collaboration, technology, and progress,” said Joel Scutchfield, general manager of SMT operations, Koh Young. “As we unite our expertise, this innovative hub promises to be a game-changer, showcasing live demonstrations, immersive training sessions, and cutting-edge smart factory solutions for advancements in electronics manufacturing.”

READ FULL ARTICLECelestica Adding Capacity in Asia to Meet Higher Demand Needs

TORONTO – Celestica is expanding at electronics manufacturing sites in Thailand and Malaysia in anticipation of greater demand for hyperscale computing applications, the company said on a conference call in January.

Celestica is raising its capital expenditure budget from 1.6% of revenue – $125 million – to 1.75% to 2.25% of anticipated 2024 revenues, said Mandeep Chawla, CFO. The EMS firm expects to front-load the capex spend as it expands capacity in support of its customers’ AI/ML compute and HPS programs.

In Thailand, Celestica is adding more than 100,000 sq. ft. of capacity over multiple phases. Phase one will come online in the current quarter and phase two is expected to be completed in the first half of 2025. The expansion, Chawla said, is “partially funded by a co-investment with one of our hyperscale customers to facilitate demand for highly specialized data center products.”

The Malaysia operations are seeing a slightly smaller expansion, where some 80,000 square feet of capacity is being added for customers in its connective and cloud solutions (CCS) segment. That expansion is expected to come online in the first half of this year, Chawla said.

Tata, Pegatron in Talks for iPhone Assembly Partnership

BENGALURU, INDIA – Tata and Pegatron are reportedly in talks to form a partnership to run an iPhone assembly plant in the Indian state of Tamil Nadu.

Tata is building the plant – its second in India – in Hosur, and is in talks to partner with Pegatron to speed up its plans to start manufacturing, two sources told Reuters.

Pegatron would provide technical and engineering support at the plant, which is expected to have 20 iPhone assembly lines, the sources said, while Tata would hold a majority stake in the venture.

Tata’s other iPhone assembly plant is in the state of Karnataka, which it took over from Wistron last year, and Pegatron operates another assembly plant in Tamil Nadu.

EMA, Hawk Ridge Systems Enter ECAD/MCAD Partnership

ROCHESTER, NY – EMA Design Automation and Hawk Ridge Systems have entered a strategic partnership to offer a full ECAD/MCAD design experience.

Through the partnership, Hawk Ridge Systems will now sell and distribute Cadence and EMA ECAD design solutions to their customers, including Cadence OrCAD X and Allegro X.

“As the ECAD and MCAD domains continue to converge, there is a great need to help customers manage the realities and requirements of a fully integrated design environment across the electrical and mechanical product development process,” said Manny Marcano, President of EMA Design Automation. “Partnering with Hawk Ridge Systems brings two companies together with unmatched expertise in electrical and mechanical design to help customers confidently deliver successfully electromechanical products on the first pass.”

READ FULL ARTICLEEpoch Expands EMS Operations, Moves to New HQ

SAN JOSE, CA – EMS company Epoch International announced the relocation of its US headquarters to a new larger facility here.

The move will permit its manufacturing subsidiary, Epoch Technologies, to double its production capacity augmented by its UL508 and ISO certification, and underscores its commitment to meeting growing demands with superior design, engineering, and manufacturing services in the North American market, the company said in a release.

The new facility’s Foreign Trade Zone (FTZ) designation and its proximity to the San Jose International Airport also make it logistically convenient and accessible to its international supply chain, Epoch said.

NationGate Acquires Hesechan Industries

KUALA LUMPUR – Malaysian EMS company NationGate Holdings announced the acquisition of Pengang-based Hesechan Industries for RM25 million ($5.2 million).

The acquisition, which includes four factories and an office block, comes as NationGate seeks to acquire additional manufacturing space to facilitate its business expansion, the company said.

“The acquisition represents a strategic investment for expansion, and is undertaken in line with NationGate and its subsidiaries’ long-term plan to grow its business,” NationGate said. “As the group intends to continue expanding its business, it envisages the requirements of additional manufacturing space to facilitate the expansion.”

Kerafol, X2F Strike Thermal Solutions Partnership

LOVELAND, CO – Kerafol and X2F are partnering to develop thermal management solutions for electronic devices using Kerafol’s thermally conductive materials and X2F’s controlled-viscosity molding technologies.

The partnership aims to provide advanced thermal management solutions that meet the ever-increasing high-performance demands of the electronics industry, the companies said in a release.

Combining Kerafol’s high-performance thermoplastic elastomeric materials with X2F’s controlled- viscosity molding (CVM) technology delivers a higher-performance alternative to conformal coating, potting, and sealing of electronics, achieving superior environmental protection and heat dissipation while reducing processing times and manufacturing costs, the companies said.

READ FULL ARTICLEIcape Makes 2 Italian Acquisitions

FONTENAY-AUX-ROSES, FRANCE – Icape Group in February announced the acquisition of the operating assets of Italian PCB distributor PCS and design company Studio E2.

A PCB producer for more than 30 years, PCS switched to printed circuit board distribution in 2015, and has a portfolio of around 80 customers from the Lombardy industrial area, from all sectors. In 2022, PCS generated an annual net revenue of more than €700,000 ($754,000).

Studio E2 has more than 40 years of experience in project management applied to all sectors of civil and industrial electronics. The company, which consists of three engineers, provides more than 70 customers with a full range of services, from printed circuit design to mechanical and electronic engineering, as well as producing the documentation required at every stage of the product’s life. Studio E2 recorded net annual revenue of more than €275,000 in 2022 ($296,000).

READ FULL ARTICLEMacDermid Enthone Opens PCB Chemistry Lab in Japan

NAGOYA, JAPAN – MacDermid Enthone Industrial Solutions celebrated the opening of its new lab here on Feb. 1 with a ribbon cutting ceremony and customer event.

The event commenced with a ceremonial ribbon-cutting for the laboratory, hosted by local MacDermid Enthone representatives and global leaders. Matthew Cenzer, principal officer, US Consulate in Nagoya, was in attendance along with automotive customers from across Japan.

“The opening of our laboratory facility in Nagoya is an exciting new chapter for MacDermid Enthone and our partners,” said Hui Hui Kiw, vice president of Asia, MacDermid Enthone. “Our local presence enables us to deliver superior customer support while bringing global capabilities to customers in Japan.”

READ FULL ARTICLECIRCUITS ASSEMBLY Opens 2024 Service Excellence Awards

PEACHTREE CITY, GA – CIRCUITS ASSEMBLY has opened registration for its annual Service Excellence Awards (SEAs) for EMS providers and electronics assembly equipment, material, service, and software suppliers.

Now in its 32nd year, the SEAs honor companies for excelling in the critical area of customer service, permitting participants to benchmark customer service against their peers. It is the only industry awards program that uses direct customer feedback to determine best-in-class.

Customers are surveyed to determine their satisfaction with a participating company in various categories, including dependability/timely delivery; manufacturing quality; responsiveness to requests and changes; technology; value for the price; and flexibility/ease of doing business. For each EMS category, the overall best-in-show winner is selected.

READ FULL ARTICLEUSCAR Announces Publication of ‘Roadmap for Automotive Smart Manufacturing’

SOUTHFIELD, MI – The United States Council for Automotive Research LLC (USCAR) in February announced the publication of its “Roadmap for Automotive Smart Manufacturing” for standards-based openness and interoperability of platforms and applications to enable a more productive, competitive and resilient automotive manufacturing environment in the US.

The roadmap was developed by a working group of USCAR, whose members are Ford, GM and Stellantis, in collaboration with CESMII – The Smart Manufacturing Institute. The roadmap’s scope includes strategies to improve interoperability of manufacturing systems and to break down digital silos of legacy platforms.

Smart manufacturing requires a high degree of automation and integration of systems on the shop floor to deliver optimal performance. These systems have evolved over decades in a highly proprietary, closed manner. The resulting landscape of incompatible machine communication creates costly delays and complexity in product launches for automotive companies. Interoperability and extensibility of these machines is imperative to ensure cost-efficient operation and viability.

READ FULL ARTICLETTM Expanding VA Operations

STERLING, VA – TTM Technologies in February announced a $13.4 million expansion of its manufacturing plant in Virginia. The expansion involves the purchase of new equipment and a renovation of its plant, which will add 43 jobs to the 200 already located in Sterling, VA.

Loudoun County awarded TTM a Commercial Business Incentive Fund grant for the expansion project, and the company received a Virginia Jobs Investment Program grant from the Virginia Economic Development Partnership.

“TTM Technologies’ decision to go all in with Loudoun is a testament to the strength of our local economy and the quality of our workforce,” said Koran Saines, supervisor, Loudon County. “This expansion will provide valuable job opportunities for Loudoun’s skilled workers and further solidify the county’s position as a leader in advanced manufacturing.”

READ FULL ARTICLETT Electronics Opens Mexico Facility

MEXICALI, MEXICO – TT Electronics has expanded its North American operations with a new manufacturing facility here. The 75,000 sq. ft. facility is equipped with the latest technology and manufacturing capabilities to meet the increasing demand for electronics manufacturing solutions in the North America region, the company said.

The plant has capacity for 250 workers and is equipped with up to six automated SMT lines.

“We are thrilled to inaugurate our new manufacturing facility in Mexico, a testament to our dedication to meeting the evolving needs of our customers and expanding our global footprint,” said Michael Leahan, chief operating officer, TT Electronics. “This strategic investment reinforces our commitment to deliver increased value, a world-class service and the capacity to enable our customer’s growth.”

PCD&F

American Standard Circuits Sunstone signed a licensing agreement with Precision Circuit Technologies.

Amitron installed a Wise outer layer tin stripper and Wise innerlayer dry-film stripper.

Gold Circuit Electronics and Shikoku Chemicals joined the High Density Packaging User Group.

Rogers Corp. signed a lease on a factory in Monterrey, Mexico, for advanced busbar manufacturing and engineering services. The first phase of the new site is slated for completion in late 2024.

Schmid is collaborating with Calumet Electronics to build its advanced substrate factory in the US.

Read Full ArticleCA

Active-PCB Solutions purchased a Kolb PSE LH7 cleaning system.

Altest purchased a Viscom 8011-III x-ray inspection system.

Anzer received a contract from Ohio State University for the RALPH (Research Assignment Learner for the Prehospital Setting) project.

Apple reportedly told its primary suppliers, Foxconn and Pegatron, to halt their plans for more production lines for the iPhone XR.

Bharat Electronics received a contract worth Rs 2,282 crore ($274.5 million) from the Indian Navy to supply an electronic warfare suite for use on warships.

Read Full Article

See us at APEX

Booth #4309

PCD&F

AT&S named Rafael Padilla senior manager, business development.

Novium named Keven Coates senior electrical engineer.

CA

Amtech Electrocircuits named Brenda Martin business development executive.

Ark Electronics appointed Bob Meyerson president of sales & business development of North America, Gene Agron VP of sales for North America, and promoted Jianli Guo to VP of operations.

ATE Solutions appointed Dean Kavanagh managing director.

Austin American Technology appointed Todd Rountree chief executive.

Éolane Group named Olivier Clément chairman.

Read full article

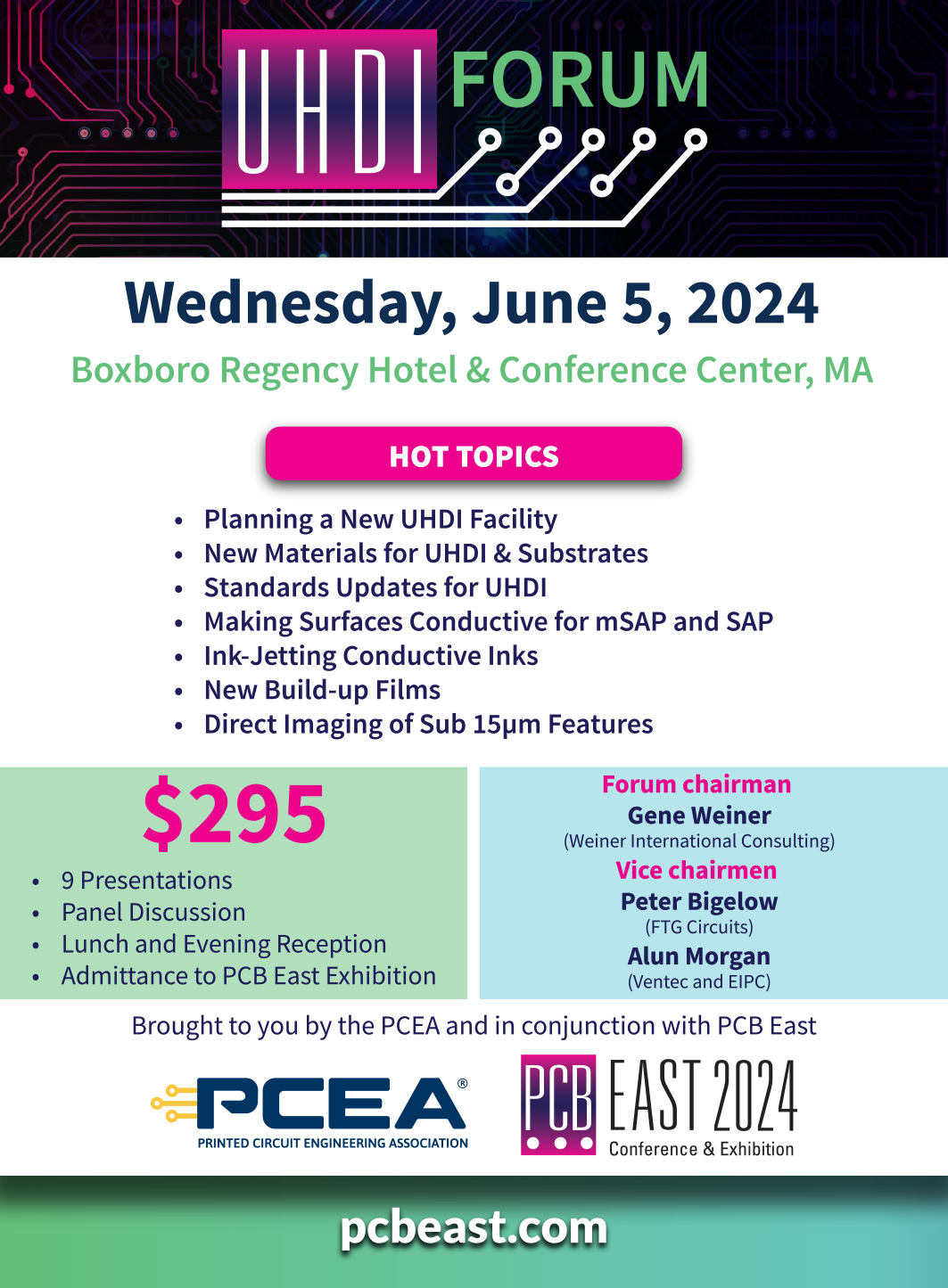

PCEA Announces UHDI Forum at PCB East

PEACHTREE CITY, GA – PCEA’s first UHDI & Substrates: Design to Package Forum will be held on June 5, in conjunction with PCB East in Boxborough, MA.

UHDI, or ultra high-density interconnect, describes lines and spaces of less than 25 microns on a printed circuit board. Among the presentations are talks on standards, electrohydrodynamic (EHD) printing, direct imaging for less than 15 microns, a new mSAP process, a new replacement for ABF (Ajinomoto Build-Up Film), planning a new UHDI facility, and new materials for UHDI.

Each presentation will be 30 minutes. The program will close with a panel discussion.

Read Full ArticlePCEA Training Announces Spring PCB Design Classes

PEACHTREE CITY, GA – PCEA Training is offering two upcoming five-day training classes starting in April and June for printed circuit engineers, layout professionals, and other individuals currently serving in the design engineering industry or seeking to get into it. The classes include an optional certification exam recognized by the PCEA.

Upcoming class dates include:

- Class 1: April 5, 12, 19, 26, and May 3

- Class 2: June 14, 17, 21, 24, 28

These instructor-led classes cover the gamut of printed circuit design engineering, from layout, place and route to specifications and materials to manufacturing methods. Schematic capture, signal integrity and EMI/EMC are also part of the comprehensive program.

Read Full ArticleNew England. The chapter plans a kickoff meeting on May 2, probably in the Andover (MA) area. Speakers include Gopu Achath of EMA Design Automation on supply chain-driven circuit design and Paul Yang of Jove PCB on embedded inductors. Contact Mike Buetow at mike@pcea.net for details.

San Diego. Stephen Chavez headlines our special chapter session taking place in conjunction with the Del Mar Electronics Show on Apr. 24. Chavez will speak on designing complex PCBs. For information, contact Luke Hausherr (luke.hausherr@freedomcad.com).

Silicon Valley. The next chapter meeting is Mar. 14 from 11:30 to 1:30 PST. The meeting topic is Design Essentials to Maintain Signal Integrity, presented by Amit Bahl of Sierra Circuits. The meeting will be held live at Levi’s Stadium in Santa Clara. Contact Bob McCreight for more information; bob.mccreight@outlook.com.

Global Semiconductor Manufacturing Industry Poised for 2024 Recovery, SEMI Reports

MILPITAS, CA – The global semiconductor manufacturing industry recovery is taking hold with electronics and IC sales increasing in the final quarter of 2023 and more growth projected for 2024, SEMI announced in its fourth quarter 2023 publication of the Semiconductor Manufacturing Monitor (SMM) report.

In Q4 2023, electronics sales edged up 1% year-over-year (YoY), marking the first annual rise since the second half of 2022, and growth is projected to continue this quarter with a 3% YoY increase. At the same time, IC sales returned to growth with a 10% YoY jump in Q4 2023 as demand improved and inventories started to normalize. IC sales are forecast to strengthen in Q1 2024 with 18% YoY growth.

Capital expenditures and fab utilization rates are expected to see a mild recovery starting in Q1 2024 after significant declines in the second half of 2023. (more)

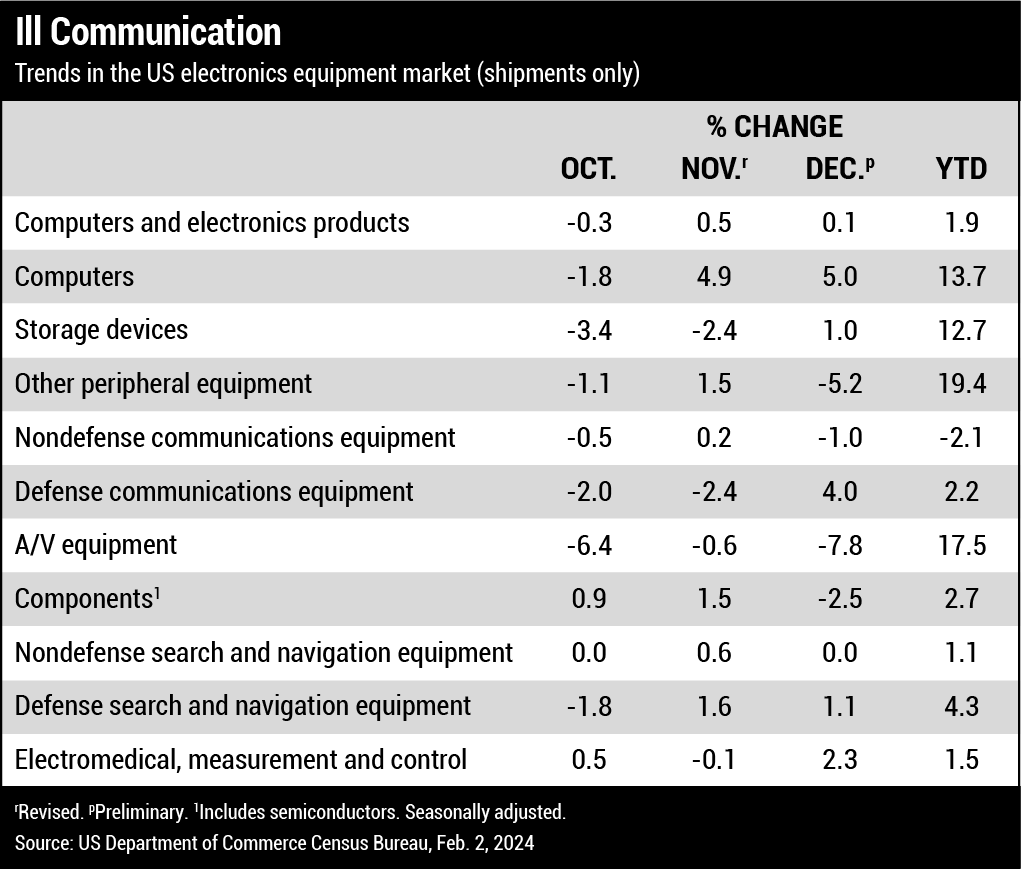

Hot Takes

Global PCB output value in 2023 will total $73.9 billion, a decline of 15.6% from 2022, but is expected to rebound in 2024 to total $78.2 billion. (Industrial Technology Research Institute)

Worldwide tablet shipments declined 17.4% year-over-year in the fourth quarter, totaling 36.8 million units. (IDC)

Demand for low-loss materials for 5G applications is expected to surpass $2.1 billion by 2034. (IDTechEx) (more)

Small Parts, Big Trouble

Quality management systems will not work without engaged personnel.

It was just a few bolts. What could possibly go wrong?

In industry, but especially in the electronics industry, nothing has changed more over the past several decades than the concept and implementation of quality management. In the early 1980s it was inspect, inspect and inspect again. In the late 1980s and through much of the 1990s, the concept of Total Quality Management, or TQM, became the rage. Manage the process and involve all the shop floor employees and stakeholders and better quality will result – requiring less inspection.

During the 1990s and continuing into the new millennium, TQM became overshadowed by Six Sigma. Applying Six Sigma, including certifying employees as green or black belts, enabled greatly improved quality. To be Six Sigma meant 3.4 (or less) defects per 1 million parts. Achieving this level was impressive for sure.

Read Full Article

Designing for PCB Manufacturability

Making a board producible is entirely in your hands.

The goal of a good documentation package is that it is complete and coherent enough to proceed with the job without any explanations, waivers, errata or feedback of any kind. It doesn’t always work that way, particularly when more than one vendor is involved. The fab drawing is more of a baseline from which they will all deviate to one degree or another. Even using the same vendor all the time is no guarantee that the DfM data come back immaculate.

The foundational aspect of PCB fabrication is a plausible phototool. That final imagery is derived from the artwork that you sent their way. What we know as global micro editing is where the phototool is crafted from the ECAD data. The artwork is more like a starting point.

Etch compensation – pre-distorting the artwork.The first item on the CAM operator’s list is dealing with etch compensation. The traces and other geometry that appear on the board are what’s left behind after the etch process. First, they must drill and plate the holes with copper. That’s done prior to etching and adds a measure of copper to the entire panel. Only then do they mask off the circuit pattern that is not to be removed.

Read Full Article

FPGA/PCB Codesign

Optimizing multidomain integration in today’s electronics.

The integration of field-programmable gate arrays (FPGAs) and printed circuit boards (PCBs) has emerged as a transformative approach to electronics systems design, giving rise to a powerful synergy that enhances performance, flexibility and efficiency. FPGA/PCB codesign, the art of seamlessly combining the capabilities of FPGAs and PCBs, has become a cornerstone in the development of cutting-edge electronics systems. This month, we’ll explore the significance of FPGA/PCB codesign, its principles, benefits and the role it plays in shaping the future of electronics.

Understanding FPGAs and PCBs. Before delving into the intricacies of FPGA/PCB codesign, it’s essential to grasp the fundamental concepts of FPGAs and PCBs and how they work together.

Read Full Article

Powering the IoT

Connecting the world will require a better energy solution.

The early stages of the IoT “hype curve” saw some wild predictions for the number of devices that would be deployed. They’re not looking so wild now, with 15 billion devices in 2020 and 29 billion expected by 2030. About 60% of these will be consumer devices, the remainder industrial, or IIoT, devices including smart meters and sensors for monitoring automation equipment, transportation infrastructures, and buildings like offices and factories.

Knowing that IPv6’s 128-bit address space would permit more than 100 IP addresses for each atom on the surface of the earth, we can see that the IoT could theoretically grow well beyond even the most ambitious predictions.

While we can solve many problems by adding more of these devices, we are creating another at the same time. Each one needs a source of energy to operate and the fact that many of them will be deployed in mobile or remote locations means a battery is the most obvious power source. Already, the US alone throws away about 3 billion batteries every year and our IoT habit could add many extra tons of hazardous waste. But there are some exciting alternatives.

Read Full Article

Getting Local

PCEA chapter meetings can be a great source of education and collaboration.

I am excited that my local PCEA chapter has gotten some traction and we are having regular meetings! After a couple years of false starts and hiccups, the Oregon/Pacific Northwest chapter got the spark and the ball rolling with members coming to connect and learn from each other. Which is exciting! I was able to reconnect with someone with whom I worked almost 20 years ago. He was attending from another country, but still views Portland as his “home area.”

As our meeting progressed, we had a good educational segment and then an active discussion about topics to discuss next time. A question came up about a mechanical exchange format, and we just happened to have someone in the meeting who works for the company that manages that format! And if we didn’t, I am sure we could have reached out to our separate networks of contacts to find an expert to talk with us about it. Meanwhile, additional topics of interest were shared, along with requests for recommendations on specific types of quality fabricators and assemblers. So add that to our list of people to invite and reach out to.

PCEA chapters meetings are great ways to network with other experts in the PCB industry and really dive into the core values of collaborating, educating and inspiring. With meetings that continue to embody these values, I know that we will all benefit.

Read Full Article

Creating the Ultra Library

Building and maintaining what’s said to be the world’s largest CAD database requires strong relationships.

by Tyler Hanes

Keeping up with the increasing demand for new and specialized components is no easy task, but Ultra Librarian’s team has proven up to the task – to the tune of more than 16 million components in its library and a quarter of a million unique downloads per month.

When we visited Ultra Librarian’s office in Huntsville, AL, in early December, EMA Design Automation had just announced the library service’s spinoff into a new ECAD-oriented company, Accelerated Designs, which was the original name of the company under its founder, Frank Frank, before it was acquired by EMA in 2016.

Frank is still with the company today as chief architect, and oversees a team that specializes in the different aspects of maintaining its CAD library.

Read Full Article

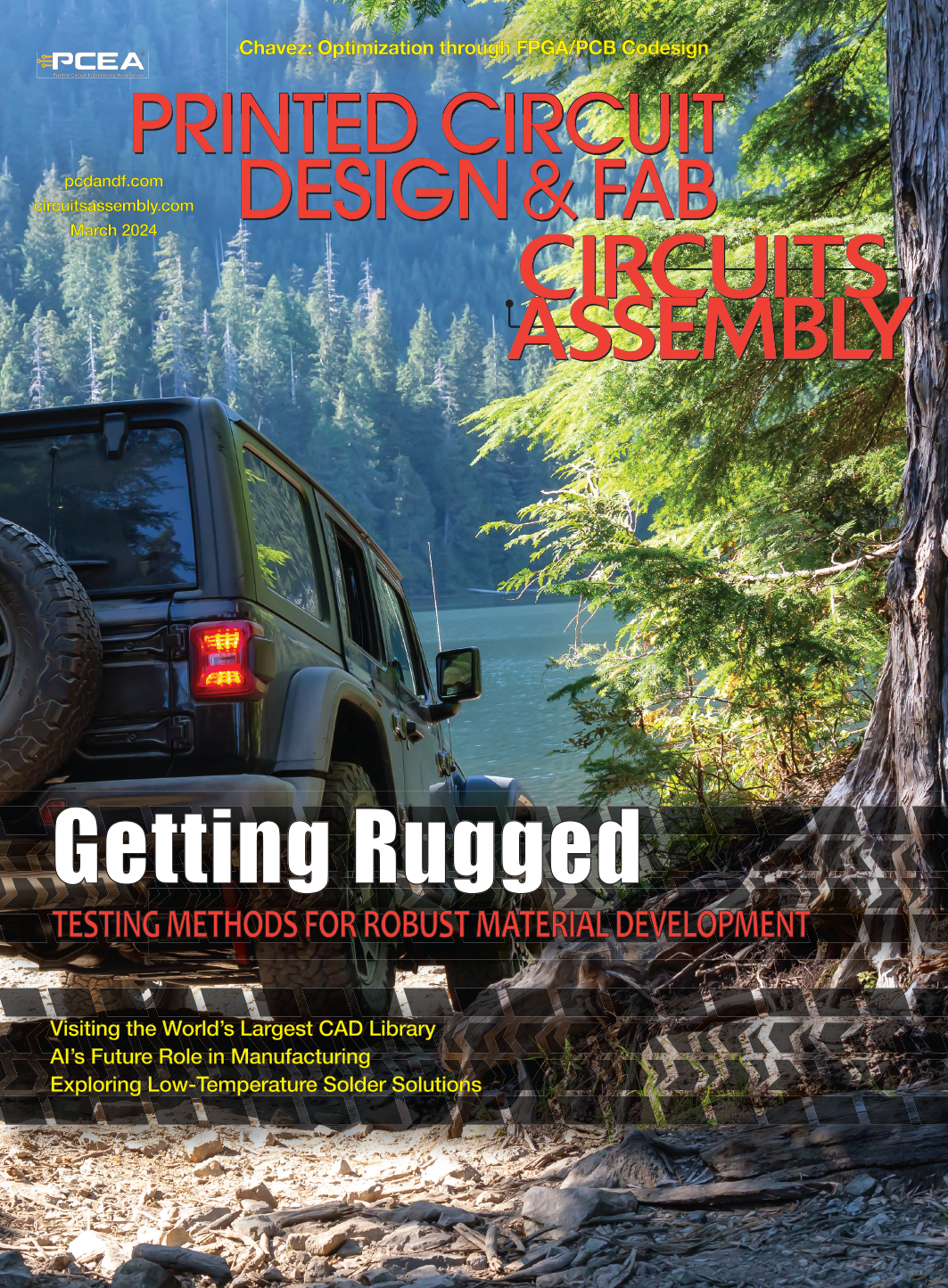

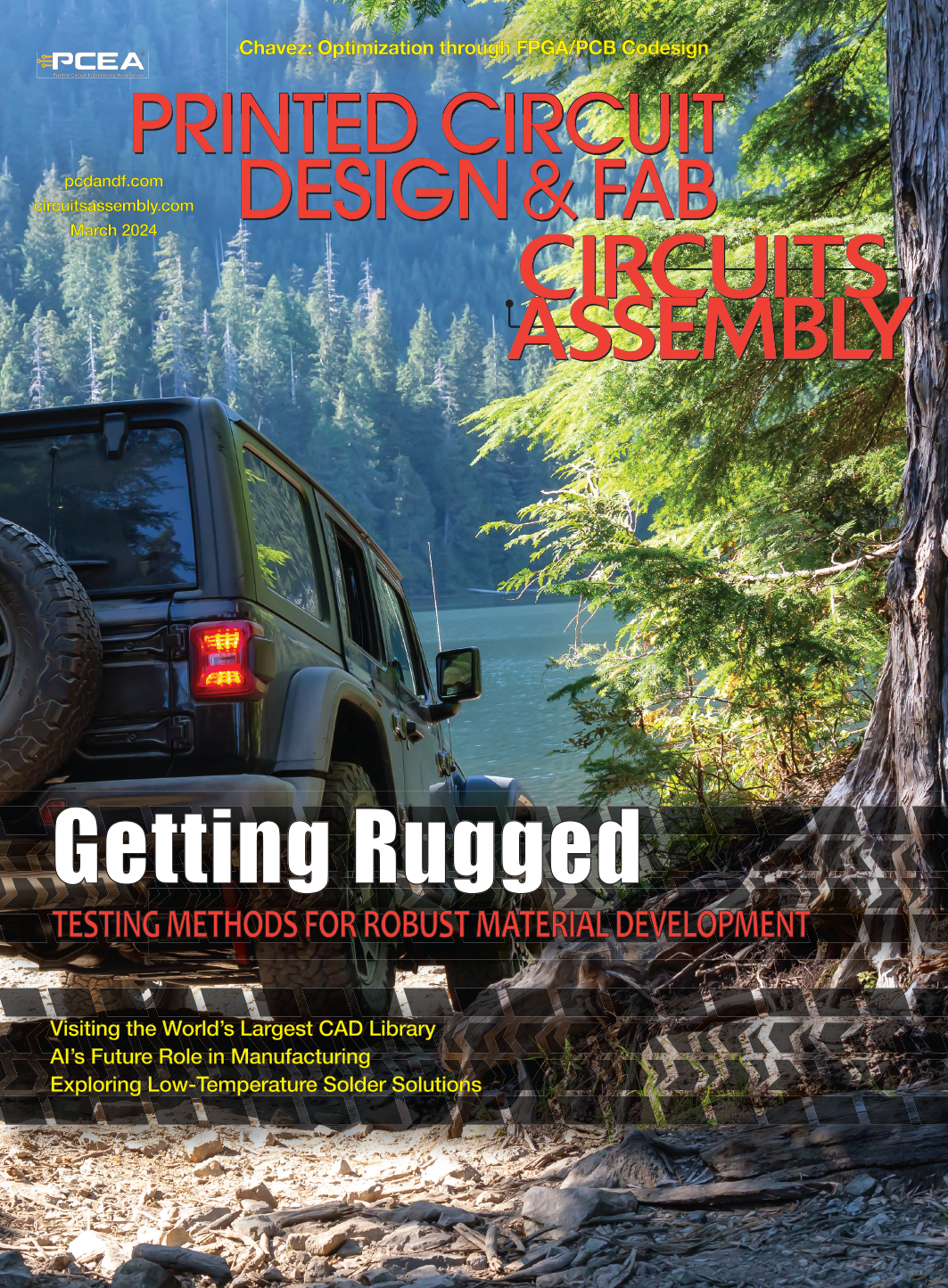

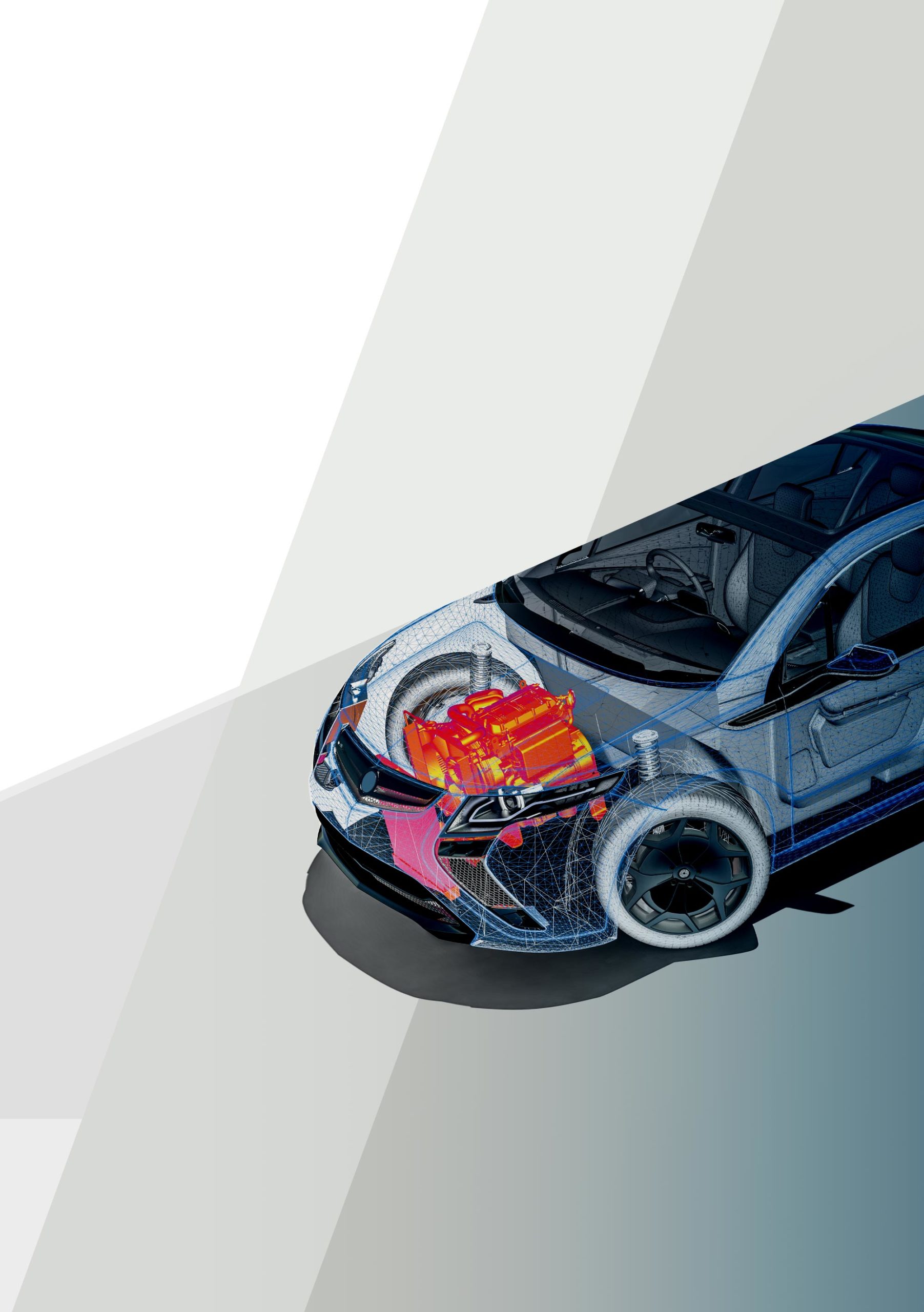

Optimized Materials to Deliver Ruggedized Electronics

A showcase of testing methods used in the development of robust materials.

by Lenora Clark, Martin Bunce, Paul Salerno and Saskia Hogan

Ruggedization means “to strengthen (something, such as a machine) for better resistance to wear, stress, and abuse.1” Automotive systems are built for aggressive environments and are categorized as ruggedized electronics. One usually thinks of an all-terrain vehicle navigating an uneven landscape in an extreme hot or extreme cold environment. The systems require more robust electronic hardware due to their unusual working conditions and environmental exposure.

Today’s automotive electronics, specifically those for advanced safety features, require ruggedization against traditional as well as additional self-inflicted abuse. The high level of processing required to execute “sense” and “respond” of multiple safety systems working in concert creates increased heat and increased mechanical strain leading to shorter characteristic life. Advanced IC substrate packages create challenges for the system as well. The need to combat these additional challenges requires specific ruggedization. This work will discuss material choices that were designed to combat temperature, vibration, heat, and various aggressive environments to offer extended system life.

The authors’ purpose is to showcase test methods used in the development of robust materials. The work will bring attention to automotive specifications such as IPC-6012DA2 but will focus on the value of material specific testing to inform us on properties and enhancements on the path to system-level testing. Predicting the needs of many different safety systems across the industry for a wide range of design criteria is impossible. The development work brings insight to the steps taken to create materials with wide operating windows that address a range of needs in the automotive space.

Read Full Article

Low-Temperature Solder: Challenges, Opportunities and Considerations

An exploration of the factors affecting the development and growth of low-temperature soldering.

by Timothy O’Neill

Low-temperature soldering (LTS) is a rapidly developing field with several potential benefits to the electronics industry. These benefits include reduced warping of components and substrates, lower energy consumption and reduced material costs. The lack of a standard solder alloy and the unique properties of emerging alloys, however, require development of new fluxes and processes for success.

Herein we explore current challenges and opportunities in low-temperature soldering, including the limited availability of low-temperature alloys, the disadvantages of high-bismuth alloys, the impact of additive elements on alloy properties, the need for new flux systems and the importance of seeking guidance from solder suppliers.

What is Low-Temperature Soldering?

No formal definition exists for “low-temperature” solder, but it generally refers to alloys with peak reflow temperatures lower than those of traditional SAC 305 and its variants. Whereas SAC 305 has a peak reflow temperature window of 230° to 255°C, these alloys typically have peak reflow requirements of 190°C or lower, with SnBi-based materials having peak reflow requirements of 170° to 190°C.

Read Full Article

Can Artificial Intelligence Solve Manufacturing Problems?

Why Andrew Scheuermann thinks AI will be the assistant every engineer has needed.

by Mike Buetow

We in electronics design and manufacturing know automation is part and parcel of what we do, but while the landscape has changed, be it the transition from mechanical drawings to CAD tools with their autorouters or from manual and semiautomatic printers and placement machines to lights-out factories where cobots have replaced operators, the industry still has a long, long way to go.

To help with perspective on this emerging technology, we interviewed Andrew Scheuermann in February. Scheuermann, along with his business partner, Tim Burke, is cofounder and CEO of Arch Systems, a Silicon Valley-based developer of software tools that collect raw machine data and use predictive and analytics to calculate manufacturing key performance indicators or KPIs.

Scheuermann has published numerous scientific papers in the areas of semiconductors, electronics manufacturing, and renewable energy. He has a Ph.D. in materials science from Stanford and is also part of StartX, a startup accelerator for company founders who are affiliated with Stanford and that has invested over $200 million in various crump companies including 13 that are now valued at over $1 billion.

Read Full Article

Lean and Quality within the Supply Chain

Outside suppliers can also affect a facility’s quality levels.

Use of Lean manufacturing philosophy and Lean Six Sigma tools have contributed to SigmaTron International’s quality and production teams achieving superior levels of quality, particularly within assembly operations. That said, even with outstanding process control, incoming material can impact achievement of Six Sigma quality levels. As a result, quality management needs to have a strategy for both ensuring supplier quality and identifying and correcting issues when that quality drops.

In this EMS provider’s model, suppliers are asked to complete a self-audit and provide applicable document examples and a copy of a Development Manual, Control Plan, PFMEA, Internal and External PPM data, Quality Reliability and Test equipment list and other documentation, if required, as part of the qualification process. If the subsequent score indicates a need for improvement, the EMS provider assigns a supplier quality engineer (SQE) who works with the supplier’s assigned stakeholders to meet the agreed-on improvement goal.

In cases where results of the self-audit or quality issues drive the need for additional scrutiny, a virtual or onsite audit may be conducted by the EMS provider. Audits for suppliers in North America are conducted by a US team and audits for suppliers in Asia are conducted by a team from the EMS provider’s international purchasing office (IPO) in Taiwan.

Read Full Article

The Price is Right?

Engineering ain’t free – even if (when) would-be customers think it should be.

Small. Size doesn’t matter.

Until it does.

Small companies and startups are often the worst: Junior Dictators consuming time in inverse proportion to the worth of their project. Much of that vaporized time has little relation to the technical specifics of the project in question.

As if they care.

Because the customer is always right (to monopolize everyone’s time).

So the micromanager’s ballet begins.

“I need it now.” “We are line down.” “How fast can you x-ray one board if we overnight it to you today?” “What happens if instead of one board, we send you four boards; how much and how fast?” “I’ll write a requisition.” “Parts are on the way: here is our tracking number. Please see if you can work this in, and get them done tomorrow, immediately upon arrival.” “Please send us a completion date as soon as parts arrive (tracking number attached).” “Stop! Put the job on hold: our customer changed their mind.” “Upon receipt, please return the board to us; take no further action beyond turning them around and returning them overnight.” “Yes, your understanding is correct: do no further work on this project.” “Our customer is making up their mind whether to proceed and seeking alternative means to do so.” “Cancel prior cancellation; please proceed: a PO will be issued shortly.” “How fast can you do this?” “Can we move to the head of your x-ray queue?” “When can we have images?” “When can we pick our boards up?” “Can one of our engineers sit with your technician during the imaging session?” “Is there someone in your organization we can talk to directly who can expedite this process?”

Read Full Article

PCD&F

Kyocera AVX 9155-800 Series Connectors

9155-800 series of vertical-mate, 2.0mm-pitch battery connector series now includes seven- and eight-position models. Features unique contact geometry that deflects cleanly when a module, mating connector or PCB is vertically pushed into position, enabling full vertical engagement in pluggable modules without the risk of contact damage. Also features forgiving sweeping beam contact design and anti-snag feature that protects contacts from damage during deflection, and when static as well. Includes gold-plated beryllium copper (BeCu) contacts said to deliver electrical and mechanical performance for more than 5,000 mating cycles and plastic locating bosses and SMT anchor tabs that maximize mechanical stability of the connector in high-shock and vibration environments. Is compatible with both signal and power circuits, and has flame-retardant (UL94 V-0) black, glass-filled Nylon 46 insulators, BeCu contacts with either 0.4µm or 0.8µm of selective gold-over-nickel plating and pure tin tails. Rated for 125VAC or DC equivalent; 1.5A or 2A, depending on number of positions (five to eight and two to four, respectively); and operating temperatures extending from -40° to +125°C.

Kyocera AVX

Littelfuse SM10 Varistor

SM10 series metal oxide varistor is designed to provide superior transient surge protection in automotive electronics, electric vehicles and various other applications. Is said to be the first surface-mounted MOV device compliant with the AEC-Q200 automotive standard, capable of withstanding high operating temperatures and offering ultra-high surge current handling in a compact package. Withstands temperatures up to 125°C and features repetitive surge capability handles up to 40 pulses of 6KV/3KA surges. Features dimensions of 15.7mm x 8.5mm x 14mm and a voltage rating of 130Vac to 625Vac.

Littelfuse

CA

Apollo Seiko SR-LYRA II Robot

SR-LYRA II soldering unit combines LYRA II soldering technology with a SCARA robot. Is engineered for high-speed, axially moving operations and is for inline applications designed for full automation. Integrates a lightweight robot and a compact controller to enhance robot mobility and simplify design of production lines. Features a virtual web-based teaching pendant, compatible with any operating system that can open a web browser, that provides a user-friendly interface for intuitive control and programming.

Apollo Seiko

ASMPT SMT Analytics Software

SMT Analytics software runs stream analytics based on the latest data processing technologies to detect causes of trouble, highlights potential losses and points out potential improvements. Features a variety of dashboards for descriptive analyses based on user profiles and process structures, and clearly defined use cases help to monitor important KPIs, locate root causes of problems and present historical, real-time and reference data in a structured and correlated manner. Makes slowdowns and shortfalls visible through intelligent data correlation and detects and prevents immediate performance shortfalls while helping to optimize processes. Also analyzes downtimes resulting from malfunctions and provides detailed information on causes and durations. Third-party-system interaction coming.

ASMPT

EMI

“Advanced Characterization of a Hybrid Shielding Solution for Reducing Electromagnetic Interferences at Board Level”

Authors: Jorge Victoria, et. al.

Abstract: The development of new advanced functionalities, miniaturization, and the aim of obtaining optimized performance in electronic devices significantly impacts their electromagnetic compatibility (EMC). As electronic components become more densely packed on a printed circuit board (PCB), unintended coupling between components can cause electromagnetic interference (EMI). These requirements result in design restrictions that make using a board-level shield (BLS) essential in reducing intra-system EMI in PCB designs. This contribution focuses on studying and characterizing a BLS solution based on combining a noise suppression sheet (NSS) with an aluminum layer to reduce intra-system EMI coupling. This hybrid solution has the advantage of providing a shielding option that does not require any electronic redesign. It does not need a footprint or a ground connection as it can be affixed over the EMI source. The solution is expected to provide higher attenuation levels than using only an NSS by combining the absorbing properties of the magnetic material and the loss mechanism of the metal. To verify the effectiveness of the hybrid BLS proposed solution, the magnetic near-field emissions of an EMI source are analyzed in this study. The experimental measurements and simulated results demonstrate a significant increase (51.6dB at 1GHz) in the shielding effectiveness (SE) provided by the proposed solution compared to a conventional NSS. (Electronics, January 2024, https://doi.org/10.3390/electronics13030598)

Read full article