November 2024

This issue of PCD&F / CA brought to you by:

PCEA

PO BOX 807

AMESBURY, MA 01913

PCEA BOARD OF DIRECTORS

Stephen Chavez, CHAIRMAN

Susy Webb, VICE CHAIRMAN

Justin Fleming, SECRETARY

Anaya Vardya, TREASURER

MEMBERS

Jim Barnes

Michael Buetow

Tomas Chester

Douglas Dixon

Richard Hartley

Matthew Leary

Charlene McCauley

Eriko Yamato

pcea.net

PUBLICATION

- PCD&F/Circuits Assembly digital.pcea.net

WEBSITES

- PCD&F pcdandf.com

- Circuits Assembly circuitsassembly.com

NEWSLETTER

- PCB Update pcbupdate.com

PODCASTS

- PCB Chat pcbchat.com

EVENTS

- PCB West pcbwest.com

- PCB East pcbeast.com

EDUCATION

- PCB2Day pcb2day.com

- PCEA Training pceatraining.net

- Printed Circuit University printedcircuituniversity.com

AWARDS PROGRAMS

- Service Excellence Awards circuitsassembly.com

- NPI Awards circuitsassembly.com

pcdandf.com

mike@pcea.net

frances@pcea.net

Peter Bigelow, Robert Boguski, John D. Borneman, John Burkhert, Jr., Stephen Chavez, Mark Finstad, Geoffrey Hazelett, Nick Koop, Jake Kulp, Alun Morgan, Susan Mucha, Greg Papandrew, Chrys Shea, Jan Vardaman, Gene Weiner

production@pcea.net

nathan@pcea.net

frances@pcea.net

will@pcea.net

frances@pcea.net

mike@pcea.net

jacqueline@pcea.net

PRINTED CIRCUIT DESIGN & FAB/CIRCUITS ASSEMBLY is distributed without charge to qualified subscribers. To subscribe, visit pcdandf.com or circuitsassembly.com and click on Subscribe.

For changes or cancellations to existing subscriptions: subscriptions@pcea.net

PRINTED CIRCUIT DESIGN & FAB/CIRCUITS ASSEMBLY is published monthly by Printed Circuit Engineering Association, Inc., PO Box 807 Amesbury, MA 01913. ISSN 1939-5442. GST 124513185/ Agreement #1419617.

© 2024, by Printed Circuit Engineering Association, Inc. All rights reserved. Reproduction of material appearing in PRINTED CIRCUIT DESIGN & FAB/CIRCUITS ASSEMBLY is forbidden without written permission.

Kicking the Gerber Habit

Dumb data won’t die. And the blame rests squarely on users who resist upgrading to formats that are designed with today’s boards and manufacturing methods in mind.

That’s the message from the PCEA Portland (OR) Chapter at its meeting in late October. The sentiment was shared across a spectrum of users, from designers to fabricators to assemblers, including the host, Axiom Electronics.

We know the issues: Too often, fabricators and assemblers receive conflicting duplicate and erroneous design data files. More often than not the culprit is Gerber-based data packages, which almost always require modification prior to fabrication or assembly.

READ FULL ARTICLE

Siemens Acquires Altair in $10B Deal

MUNICH – Siemens has signed an agreement to acquire Altair Engineering for $113 per share, representing an enterprise value of approximately $10 billion.

The acquisition of the simulation software provider will increase Siemens’ digital business revenue by 8%, adding around EUR600 million ($651 million) to its revenue of EUR7.3 billion ($7.9 billion) in fiscal year 2023, the company said, and providing Altair full access to its global footprint and customer base should have a revenue impact of more than $500 million per year in the mid term and more than $1 billion per year in the long term.

“Acquiring Altair marks a significant milestone for Siemens,” said Roland Busch, president and CEO, Siemens, said in a release announcing the acquisition. “This strategic investment aligns with our commitment to accelerate the digital and sustainability transformations of our customers by combining the real and digital worlds. The addition of Altair’s capabilities in simulation, high performance computing, data science, and artificial intelligence together with Siemens Xcelerator will create the world’s most complete AI-powered design and simulation portfolio.”

READ FULL ARTICLETTM Receives $30M from DoD to Fund Expansion

SYRACUSE, NY – TTM Technologies received a $30 million grant from the US Department of Defense to help fund an expansion of its PCB manufacturing capabilities.

The grant, facilitated through the Defense Production Act Purchases (DPAP) office, will enable TTM to acquire and install advanced manufacturing equipment and develop prototype designs for printed circuit boards. The project will begin at TTM’s Centers of Excellence across the US and culminate in integration into its new Syracuse facility.

“The DoD requires state-of-the-art advanced printed circuit board manufacturing capability to support defense programs,” said Dr. Laura Taylor-Kale, assistant secretary of defense for Industrial Base Policy. “This project provides domestic manufacturing capabilities to meet demand for current and future US systems.”

READ FULL ARTICLEWürth to Close PCB Plant After Drop in Orders

NIEDERNHALL, GERMANY – Würth Elektronik will close its PCB production plant in Schopfheim, Germany, citing a “dramatic decrease” in orders due to weakness in the European electronics industry. The closure affects more than 300 jobs at the facility.

The company said the region’s economic crisis has reached historic proportions, particularly in the industrial electronics sector, leading to a sharp decline in European PCB manufacturers as orders shift to China and other countries. It said the situation is exacerbated by massive increases in energy and personnel costs, as well as geopolitical and economic uncertainty.

The demand from other industries that rely heavily on regional value creation is too low to permanently utilize the capacities of all Würth PCB production facilities, including medical technology and aerospace, the company said.

Read Full ArticleVentec Consolidates German Facilities

KIRCHHEIMBOLANDEN, GERMANY – Ventec in October announced plans to consolidate two facilities here into a single production and logistics center. The company said the project is scheduled to be completed in the fourth quarter of 2025.

Following the company’s acquisition of Holders Technology in October 2021, Ventec has two separate facilities in this southwestern Germany town, and the company said it plans to consolidate the two and upgrade a 13,500 sq. ft. campus with modern offices, fully equipped production halls and a new 1,800 sq. m. warehouse.

The enhanced facilities will include an enlarged prepreg cutting cleanroom, a new hall for cutting the company’s laminate materials and state-of-the-art drilling and milling machines. The facility will also include a modern dust-extraction system that meets the latest CO2 reduction requirements, as well as solar power and heat pumps to ensure the buildings meet the latest eco guidelines.

READ FULL ARTICLEVVDN to Build PCB Plant in India

MANESAR, INDIA – VVDN Technologies plans to invest up to $200 million in a new PCB fabrication and connectors facility, part of a larger strategy for the ODM to ensure a steady supply chain for key components and lessen its imports from China.

The new plant is expected to come online within three to four years, said Vivek Bansel, president of VVDN, according to published reports.

VVDN is one of India’s largest electronics ODMs.

Amber, Korea Circuit Form JV for PCB Production

GURUGRAM, INDIA – Amber Enterprises has signed a joint venture with Korea Circuit to manufacture advanced printed circuit boards in India.

Amber said the partnership is aimed at addressing India’s growing demand for electronics, and through this collaboration, the companies plan to bring cutting-edge technology and manufacturing processes to the nation’s market.

Amber and Korea Circuit will own 70% and 30% of the joint venture, respectively, which will focus on manufacturing high-density interconnect (HDI) PCBs, flexible PCBs, and semiconductor substrates.

AT&S Sells Korean Plant to Somacis

LEOBEN, AUSTRIA – AT&S in September completed the sale of AT&S Korea, including its PCB manufacturing plant in Ansan, South Korea, to Somacis for around €405 million ($452.8 million). The transaction is subject to regulatory approval and is expected to be completed in the next few months.

“With the sale of the plant in Ansan we aim to further sharpen the group’s strategic profile,” said AT&S CFO Petra Preining. “We strongly believe that with the Italian technology group Somacis as its new owner, the Ansan site will unleash its full potential and continue pursuing an attractive journey of strong growth.”

“Ansan is an AT&S success story,” said CEO Andreas Gerstenmayer. “When AT&S acquired the plant in 2006, all revenue was generated locally, and its performance was far below the expectations of AT&S. The development of new applications, strong investment in technology and capabilities, as well as the strong commitment of the responsible team resulted in strong revenue growth and a significant improvement in performance. Within only a few years, revenue quadrupled.”

READ FULL ARTICLEScanfil Acquires Asia-Pacific Manufacturer SRXGlobal

OULU, FINLAND – Scanfil in October announced the acquisition of SRXGlobal and its factories in Melbourne, Australia, and Johor Bahru, Malaysia, for €23.3 million ($26 million).

Between the two factories, SRX has eight total SMT lines and around 300 employees.

“The acquisition of SRX is a step in building our presence in Asia-Pacific region and the implementation of our strategy,” said Scanfil CEO Christophe Sut. “It creates synergies in procurement, improves geographic diversification and strengthens our customer portfolio. The acquisition brings us new customers and allows our existing customers to expand their operations with us in the new areas of the fast-growing Asia Pacific region.”

Read Full ArticleJabil Acquires Thermal Management OEM

ST. PETERSBURG, FL – Jabil in October announced the acquisition of Mikros Technologies, a manufacturer of liquid cooling solutions for thermal management.

Jabil said the continued adoption of AI, energy storage and electric vehicles is driving higher-power density systems, and liquid cooling has emerged as a more energy-efficient alternative to air cooling for many applications.

The company said the acquisition of Mikros will enable Jabil to help its customers manage the intense thermal requirements of their current and next-generation products while considering sustainability and cost considerations.

READ FULL ARTICLEFlex to Acquire Crown Technical Systems

AUSTIN, TX – Flex entered a definitive agreement to acquire Crown Technical Systems, a specialist in power distribution and protection systems, for $325 million.

Crown Technical Systems brings nearly three decades of power distribution and control experience, with capabilities in modular solutions, medium-voltage switchgear, and control and relay products. The company has customers in utilities, data centers and power generation, and has facilities in California, Texas, and Canada.

“The addition of Crown Technical Systems strengthens our position to help customers solve power, heat, and scale challenges in the data center space aligned with our long-term growth strategy,” said Flex CEO Revathi Advaithi. “This acquisition reaffirms our commitment to differentiate our value through our EMS + Products + Services strategy that will deliver longer-term shareholder value.”

READ FULL ARTICLEMycronic Buys German AOI Maker

TÄBY, SWEDEN – Mycronic has acquired Modus High-Tech Electronics, a German provider of automated optical inspection systems.

Modus specializes in automated optical inspection units for coating, soldering and components within printed circuit board assembly, and has also developed solutions for fuel cell inspection. The company was founded in 1999, has 18 employees and more than 1,650 scanners and 650 camera systems in service. Its net sales in 2023 amounted to €4 million ($4.3 million).

“Modus’ inspection systems are an integral part of conformal coating production lines, where Mycronic’s High Volume division is a global leader in electronics conformal coating solutions. Together we will be able to offer complete and optimized solutions to our respective customers,” said Ivan Li, senior vice president, high volume, Mycronic.

Aimtron Expands Operations After Public Listing

AHMEDABAD, INDIA – Aimtron Electronics announced an expansion of its domestic electronics assembly operations in India after a public listing earlier this year.

The company said the public listing marks a significant milestone in its journey, providing greater financial flexibility and an opportunity to accelerate its strategic initiatives.

“India holds tremendous potential in electronics manufacturing, and we aim to be a major contributor to that growth. Our goal is to ensure that a significant share of our production and innovation happens within the country,” said CEO Mukesh Vasani.

READ FULL ARTICLEReport: Jabil Looks to Expand India Investments

ST. PETERSBURG, FL – Jabil is looking to invest an additional $250 million to $275 million in India over the next few years for at least two more manufacturing units, the Economic Times reported.

The company currently has two units in Pune where it manufactures plastic casings for Apple’s AirPods, and could be looking to make plastic casings for chargers, some older iPhone models, AirPods or components for Apple watches and Mac computers, according to ET’s report.

As Apple continues to look to India as an alternative to China, 13 of its suppliers, including Zhen Ding Technology, TDK Corporation, Tata Electronics, Sunwoda Electronic Company, Shenzhen YUTO Packaging Technology, Jabil and Foxconn, have manufacturing and assembly facilities in the country.

PCD&F

All Flex Solutions installed an Omron VP9000 3-D solder paste inspection system and a VT-S1080 3-D AOI for its flexible circuit fabrication and assembly facility in Bloomington, MN.

Ascent Circuits will invest INR650 crore ($77 million) to build a PCB manufacturing facility in Hosur, India.

Dynamic Electronics joined High Density Packaging User Group.

Nano Dimension will acquire 3-D printer manufacturer Markforged for $115 million. The transaction is expected to close in the first quarter of 2025, subject to the satisfaction of customary closing conditions.

SpaceX expects its new facility in Austin, TX, to become the largest factory for printed circuit boards in the US, according to president Gwynne Shotwell.

Read Full ArticleCA

Absolute EMS expanded its PCB assembly capabilities to meet the demands of the AI industry.

American Circuits opened a 37,000 sq. ft. production facility in Charlotte, NC.

Apple is set to move AirPod production to Foxconn’s factory in Telangana, India.

Bransys installed two Rehm VisionXP+ Nitro 3850 Type 834 reflow ovens.

Cambodia is striving to promote the development of the automotive and electronics industries in the country to keep pace with global advancements.

Read Full Article

PCD&F

Dynamic Electronics named Mike McMaster engineering director.

Victory Giant named Dana Korf technical director, US.

Ventec promoted Bill Wang to group technical vice president.

CA

Altus Group appointed Ella Gwilliam operations and planning assistant.

Austin American Technology added Dustan Carr to its service team.

Benchmark Electronics appointed Bryan Schumaker CFO.

Bright Machines appointed Chris Stori CEO.

Cirtronics appointed Patrick Moody president and CEO.

Read full article

PCEA Names Webb, Schmidt Award Recipients

PEACHTREE CITY, GA – PCEA in October announced Susy Webb recipient of the third annual PCEA Leadership Award and Stephan Schmidt recipient of the third annual PCEA Membership Award. The announcements came at the PCEA annual meeting in conjunction with the PCB West conference and exhibition.

The Leadership Award recognizes members who have made significant, long-term contributions to the association and the industry. The Membership Award recognizes individuals for standout contributions to their local chapter.

Webb is vice chairman of the PCEA Executive Board and a member of the Education Committee and Conferences Task Group. She co-authored PCEA’s Certified Printed Circuit Professional training and certification curriculum, and is a regular speaker at PCB East and PCB West, and international design conferences, and consults for individual companies and PCEA chapters. She is a former writer/columnist for PCD&F, a chapter writer for Clyde Coombs’ Printed Circuits Handbook, and one of the judges for the annual Siemens TLA competition. A senior PCB designer with 40 years of experience, her career includes experience in coastal and oceanographic oil exploration and monitoring equipment, point-to-point microwave network systems, and CPCI and ATX computer motherboards.

Read Full ArticleMembers Vote to Relocate PCEA

PEACHTREE CITY, GA – PCEA members voted unanimously at the annual meeting in October to support a board of directors’ recommendation to redomesticate the corporation to the state of Georgia.

The members also endorsed the slate of directors for 2025-27, including Jim Barnes, Stephen Chavez, Tomas Chester, Doug Dixon, Justin Fleming, Rick Hartley, Matthew Leary, Charlene McCauley, Anaya Vardya, Susy Webb and Eriko Yamato. PCEA president Mike Buetow rounds out the board.

The meeting was held during the PCB West conference and exhibition at the Santa Clara (CA) Convention Center.

PCEA was incorporated in California in March 2020. Following the acquisition of UP Media Group in January 2022, PCEA moved its headquarters to Georgia, where most of the new employees were based.

Missouri. The new Missouri chapter will sponsor a talk on DfA by Dale Lee, staff DfX process engineer at Plexus, in January. For details, visit https://attendee.gotowebinar.com/register/506313452873561692.

Portland, OR. We held a live meeting at Axiom Electronics in October. Featured speakers included Matt Stevenson of ASC Sunstone on design for fabrication, Rob Rowland of Axiom on design for assembly, and Dana Korf of Victory Giant on electronics data transfer. The next meeting takes place Nov. 21 via Zoom and features John Johnson of American Standard Circuits presenting on design guidelines for RF PCBs. Those interested should email stschmidt@pcea.net.

Summer Doldrums Hit Japan’s PCB Market

TOKYO – Japan’s printed circuit board recovery remained mixed in August, as rigid board sales fell nearly 10% year-over-year on a nearly 13% drop in production output.

The data are compiled by the Japan Electronics Packaging and Circuits Association (JPCA) based on reporting from scores of domestic manufacturers.

Flex boards were nearly flat, growing 0.7% from a year ago in sales, while output was down about 7%. IC substrate sales were the outlier, rising 11% for the period despite a production drop of about 2%.

For the year, flex circuits sales are up 6.5% on a 1.3% rise in output. Rigid board sales are down 5.4% on a 13% drop in output, and IC substrates are down 11% in revenues despite a 10% increase in output. (more)

Hot Takes

Fourth-quarter memory prices will see a significant slowdown in growth, with conventional DRAM expected to increase 0-5%. (TrendForce)

Global smartphone shipments increased 4% year-over-year to 316.1 million units in the third quarter. (IDC)

North American EMS shipments in September were up 10.3% year-over-year and 2% sequentially. Bookings rose 19.6% from a year ago but fell 10.8% from the previous month. (IPC) (more)

The Costs of Complacency

With more supply chain crises brewing, be proactive in your preparations.

The various issues that have beleaguered the supply chain, and those companies and individuals that rely on it, continue to baffle me. I fully understand that when Covid emerged on the scene, especially as quickly as it did a few years ago, the global supply chain, as well as so many other aspects of our “normal” life, came to a grinding halt. But that was then, and this is now, so I cannot stop thinking, “What does this all mean?”

That companies were forced to shut down, whether partially or completely, for lengthy periods of time while the pandemic was in full rage is understandable. Safety of employees and the fear of what might or could or is happening to public health have a way of moving to center stage in people’s minds and habits, regardless of where they live or what they do for a living. It was understandable that shortages occurred with factories’ production levels slashed for the health and safety of employees.

The tariffs being levied on everything imaginable – from both sides of the world – did not help. When it is economically more lucrative to sell into some countries and not others, the supply chain pivots to the more lucrative option. Couple that pivot with slashed production levels from factories across the globe, and the availability of the limited inventories gets further skewed, with some areas being relative winners while others are losing.

Read Full Article

EMS Sales Teams: Digital Failures?

A comprehensive website is a salesperson’s best friend. So why don’t more EMS companies have one?

I read an article reposted on LinkedIn where a buy-side (pay-to-play) consulting group demeaned the EMS industry salesperson’s communication skills and blamed them for the dysfunctions within our industry. The premise was that, because Covid prohibited face-to-face engagements, the business development person’s lack of digital communications and their inability to redirect their sales efforts digitally were a root cause for woes in our industry today.

The EMS industry has been slow to embrace the digital world. But to assert that corporate digital dysfunction is an individual salesperson’s issue implies that one’s own accounts on LinkedIn, Facebook and X (Twitter) will drive enough deals to shore up a flat or declining EMS business. While I encourage my clients’ sales teams to utilize these platforms for various communications, gaining industry knowledge, networking and infrequent lead generation, they make up a tiny element of what an EMS company should undertake to optimize its digital sales opportunities and boost a sales process that even now has somewhat limited face-to-face engagements. Does your EMS company suffer from elements of this discussion? Let’s start a corrective action process.

First, consider your website. When was it last updated? I review many EMS websites, and when compared to their corporate company overviews, I often find conflicting or missing important elements on the sites. Your website should be your 24/7 salesperson. It doesn’t close deals; humans still do that. But many OEM outsourcing searches start with a “silent review” of an EMS website. Many times, the EMS is unaware of that OEM “hit” and no sales follow-up occurs. Do you have analytics connected to your site’s traffic and is there a process to follow up on relevant searches? Does your company optimize (SEO) the site so you show up early on a list of potential EMS companies from an OEM’s search?

Read Full Article

Solder and Stencil Considerations for Double-Sided PCBs

Accounting for the assembly process will put your design on the fast track.

Thought-provoking questions keep coming my way, and then it’s down the old rabbit hole. So it goes something like this: “How do we integrate so many different parts in such a small PCB area?” The answer is a little deeper than the geometry of Tetris, but that’s a good illustration of packing the available space. This, of course, starts with the CAD symbol library and manifests in the assembly yields at the factory. We have to connect those dots.

Once the PCB logic is sufficiently captured, placement studies can start. Pay attention to the spacing and orientation of components. The interrelationships of neighboring parts can affect the solderability of the overall PCB. The assemblers like to see a consistent rotation of the components and an even distribution across the board.

It’s unlikely that every device on the board will be able to meet that preference. The electrical performance is going to take priority in several cases, particularly with analog designs. That said, you can still pick an orientation that suits most components. The similarity will inform the manufacturing engineer how the board should travel along the placement machinery and guide the soldering process.

Read Full Article

Where are the Wearables?

The smartwatch has lived up to the hype. Can other wearable technologies follow its lead?

Will wearable technology ever realize its potential? Exciting technical innovations that should succeed often disappoint commercially, failing to take off for reasons that can be difficult to define.

Some forecasters would already have us walking around in clothing made from smart textiles that can monitor vital signs such as respiration and body temperature, track sports performance or fatigue levels, or assist treatment such as posture correction or physiotherapy. On the other hand, we could be routinely interacting with the world through AR glasses that overlay everything we need to know, wherever we are, minute by minute, and record our experiences wherever we go. And perhaps our wearables should be battery-free, powered by energy-harvesting technologies that can turn movement, daylight, or even the difference between hot and cold, into enough electrical energy to keep us connected all the way to the furthest extremities of the grid.

While these all have their place in the modern world – augmented reality is making inroads in industrial scenarios such as on production lines and in vehicle maintenance, and controls powered by ambient energy have been commercialized for smart-building applications – the massive, all-pervading adoption within consumer markets has not come about.

Read Full ArticleThe Future is Thin, Flat and Flexible

What’s ahead for antennas, heaters and inks.

by Michael LeFebvre

In the 39 years I’ve been in the printed electronics industry, I’ve had the privilege of witnessing, influencing and playing a part in life-changing innovations such as the SonoCine ultrasonic breast imaging device and printed wearable therapeutics. As brilliant as these breakthroughs were back in the day, however, they don’t hold a candle to today’s conductive transparent thin films that are enabling limitless design and engineering possibilities.

The following is a synopsis of some of the leading-edge technologies and their applications. After reading about the following examples based on my current experience, I think you’ll agree that the future of our industry is exciting indeed!

Aesthetic and Green

Transparent, flexible antennas. Today’s 5G frequencies don’t penetrate buildings well, and the need for more antennas to facilitate 5G speed is growing exponentially. The problem is that consumers don’t want unsightly features (read: antennas) attached to their products or visible anywhere within their environments.

Read Full Article

Rocking and Rolling at ZIW

The annual user event was tuned into AI, but that’s not the only melody being played.

by Tyler Hanes

Zuken welcomed customers and partners to Cleveland in September for the electronics design software company’s annual users event, providing an opportunity for networking and a backstage pass to the company’s most recent software updates and future innovations.

Zuken Innovation World Americas, colocated with Vitech’s Integrate24, opened with comments from Kent McLeroth and Enrique Krajmalnik, the chief executives of Zuken USA and Vitech, respectively, and a keynote address befitting its location in the supposed birthplace of rock and roll with Mark Schulman, drummer for such artists as P!NK, Billy Idol, Foreigner and Cher.

Schulman shared his musical journey and some of the lessons learned from rock’s legends, as well as his own methods to change his perspective and enter a “rock star” state of mind – whether on the stage or in daily life.

Read Full Article

ENEPIG Corrosion Mechanisms

Different types of nickel corrosion and potential mitigation strategies.

by Patrick Valentine

Electroless nickel immersion gold (ENIG) chemistries were introduced in the mid-1990s to replace electrolytic nickel and gold for high-density circuits. In the mid-1990s, nickel corrosion, soon to be known as the ubiquitous “black pad,” was discovered. Chemical suppliers and board manufacturers took steps to reduce the occurrence of black pad. To that end, in 2002, IPC released IPC-4552, “Performance Specification for Electroless Nickel/Immersion Gold (ENIG) Plating for Printed Boards.”

In the late 1990s, electroless nickel electroless palladium immersion gold (ENEPIG) chemistries were introduced as a universal finish for gold, aluminum and copper wire bonding, with perceived protection from black pad. In 2013, IPC released IPC-4556, “Specification for Electroless Nickel/Electroless Palladium/Immersion Gold (ENEPIG) Plating for Printed Boards.” Today, black pad is still a reality with ENIG and ENEPIG plating.

Electroless Nickel Deposition

The most common electroless nickel baths for printed circuit boards (PCBs) use a phosphorous-containing reducing agent, typically incorporating ≤10% phosphorous, by weight, in the nickel deposit. The nickel phosphorous (Ni-P) deposit is amorphous and has an isotropic surface energy. This produces a Ni-P deposit with hemispherical nodules that look like soap bubbles (Figure 1).

Read Full Article

Royalty Flush

A noted solutions architect offers an audacious plan for AI acceptance. It just might work.

by Tyler Hanes

The talk of AI-based printed circuit design – and the idea that artificial intelligence could theoretically design a board faster and more efficiently than a human – has inevitably led to the fear that designers will be replaced by their algorithmic counterparts.

Rather than stoke those fears, a proposed process for AI implementation presented by a leading ECAD architect at PCB West in October focused on the new opportunities that could come for designers as AI implementation begins to take place.

That proposal, offered up in the keynote address by Charles Pfeil, was the precursor to several panels and conference sessions at this year’s conference, apropos as AI and its impact on PCB designers is front and center on the minds of many in the industry as AI continues to grow.

Read Full Article

When to Downsize Solder Paste Powders

Smaller components do not always need a smaller paste.

by Gayle Towell

As components shrink in size, the demand for finer solder pastes increases. But the selection of solder paste is not just about matching component size; it’s also about optimizing printing and reflow processes to prevent defects and ensure reliability.

Here we explore the significance of solder paste powder size, particularly when and why manufacturers should consider downsizing from standard types to finer alternatives.

The exact method for creating solder powder, and ultimately solder paste, can vary significantly from one manufacturer to another. These differences in production methods can lead to very different outcomes when printing with a particular paste size.

Read Full Article

Keeping Electronics Cool

Types of TIMs and their application methods.

by Nathan Preslan

As demand for high-performance electronic devices continues to grow, managing heat dissipation effectively has become a critical challenge. Thermal interface materials (TIMs) are pivotal in ensuring efficient thermal management by facilitating heat transfer between heat-generating components and heat-dissipating devices. Here, we examine the various types of TIMs and their application methods, including insights into modern dispensers and the advantages and disadvantages of these methods in electronics manufacturing.

In the electronics industry, thermal interface materials are integral to various applications, including processors and GPUs, power electronics, memory modules, automotive electronics and telecommunications. For example, TIMs are used between processors or GPUs and their heatsinks to ensure efficient heat transfer, preventing thermal throttling and enhancing performance. This issue has been magnified by the recent surge in AI-related hardware, which often requires significantly more processing power and generates more heat that must be managed effectively.

Other high-power components, like power transistors and LEDs, also generate significant heat, and TIMs help maintain optimal operating temperatures, prolonging the lifespan and reliability of these components. Memory chips, especially those in high-performance applications, benefit from TIMs as they manage heat dissipation and maintain thermal stability.

Read Full ArticleEvaluating Equipment Tradeoffs

Do multiple single-spray-nozzle conformal coaters outperform a three-nozzle machine for volume builds?

Electronics manufacturing services (EMS) providers often have to evaluate equipment selection tradeoffs on more stringent standards than original equipment manufacturers due to their needs for flexible capacity across multiple clients.

In one recent example, the engineering team at SigmaTron International’s Chihuahua, Mexico, facility needed to evaluate whether multiple single-spray-nozzle automated conformal coating machines would be a better choice for a high-volume project than a single machine customized with three spray nozzles.

The argument in favor of multiple single-nozzle machines was the flexibility they could provide in addressing the needs of other projects, plus the redundancy they provided should one machine have unanticipated downtime. Customizing a single machine with three nozzles cost less than three machines, took up less space on the factory floor and reduced setup and cleanup time. The potential negative to the single machine option, in addition to the lack of redundancy for unanticipated downtime, was that most other projects would require only a single nozzle, utilizing only a third of the custom machine’s capacity.

Read Full Article

Profiles in Delusion

Unreasonable demands warrant blunt responses.

A young man called me. He didn’t want to call me. It was Friday. Friday is for vanishing, not confrontation. He persisted throughout the preceding week in sending emails, hoping someone on our end would engage. No one did. Not our customer service manager. Not our operations manager. Not our business/office manager. Without exception, all directed the young man to me.

Options reduced to one, he finally capitulated and called me. He was audibly nervous. He talked fast. When I was allowed the (rare) opportunity to reply, he cut me off and talked over my answer. The ensuing word jumble accomplished nothing. In exasperation, I finally admonished him, “You know, studies show that a conversation works optimally when the first party speaks and the second listens, after which the roles reverse. Can we try that as an experiment in achieving better communication?” He seemed reluctant. He kept on speaking nervously. Clearly, he did not appear comfortable with the message he was assigned to deliver.

That message was this: He wanted more time to pay us. More accurately, Higher Authority was dictating more time. Blame one customer: They wanted payment terms extended from the conventional net 30 to their requested net 90. Ominously, the request stated that their customer was expecting uniform acquiescence to their grand idea from all suppliers to “maintain this growing partnership ….”

Read Full Article

PCD&F

AGC Meteorwave ELL PCB Materials

Meteorwave ELL multilayer PCB materials are said to achieve low transmission loss and high thermal resistance. Contribute to higher capacity, higher transfer rates and lower power consumption of data communication, with reliability in high-temperature environments and UL-94 V0 certification. Come in a variety of prepregs and constructions and are for use in applications such as telecommunications, core routers, high speed switching/routing systems, cloud storage, aerospace, automotive, radar and AI.

AGC

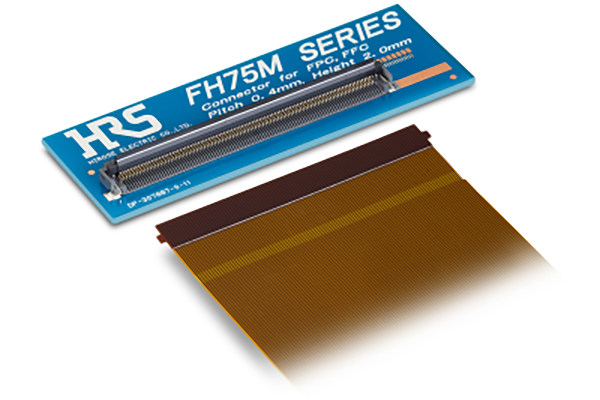

Hirose FH75M FPC/FFC Connector

FH75M series flexible printed circuit/flat flexible connector supports MIPI D-PHY (1.5Gbps) and eDP1.3 (5.4Gbps) specifications in a miniature footprint. Features a 0.4mm pitch and 2mm height and uses a two-point contact design with two independent springs that provide a wiping action to prevent contact failure from dust, dirt and other contaminants. Operating temperature of up to 125°C. Meets automotive requirements for shock and vibration resistance, hydrogen and sulfur gases, humidity and corrosion. Uses a flip lock with FPC tab and housing side catches that offer a retention force of 51.4N and delivers easy FPC insertion while emitting a clear tactile click to confirm complete locking. User-friendly design has wide tapers that provide smooth FPC insertion, and comes in 100-position version that is halogen-free and RoHS compliant.

Hirose Electric

CA

CheckSum ILS-X2 Multi-Tester

ILS-X2 dual panel automated test system is said to effectively double parallel test output by supporting the handling and testing of two panels simultaneously. Enables more tests to be performed in parallel, integrating ICT, ISP and parallel functional tests like LIN, CAN, BIST, current, voltage and others.

CheckSum

Emil Otto EO-B-016 Fluxes

EO-B-016 flux series now includes versions with different solids content. EO-B-016A features 2% solids, EO-B-016B has 3% solids and EO-B-016C has 4% solids. Are all high-efficiency no-clean fluxes based on alcohol with di-carboxylic acid activator complex and synthetic resin, and can be used in wave, selective and hand soldering processes as well as in dip soldering and strand tinning. Applicable using all standard application methods except foaming and are said to be versatile and OPS-compatible.

Emil Otto

In Case You Missed It

Defect Detection

“A Novel YOLOv5_ES Based on Lightweight Small Object Detection Head for PCB Surface Defect Detection”

Authors: Yi Gao, et. al.

Abstract: In the manufacturing process of printed circuit boards (PCBs), surface defects have a significant negative impact on product quality. Considering that traditional object detection algorithms have low accuracy in handling PCB images with complex backgrounds, various types and small-sized defects, this work proposes a PCB defect detection algorithm based on a novel YOLOv5 multi-scale attention mechanism spatial pyramid dilated convolution (SPD-Conv) (YOLOv5_ES) network using improved YOLOv5s framework. First, the detection head is optimized by removing medium and large detection layers, leveraging the capability of the small detection head to identify minor target defects. This approach improves model accuracy and lightweighting. Second, to further reduce the number of parameters and computational costs, the SPD-Conv is introduced to improve feature extraction capability by reducing information loss. Third, an EMA module is introduced to fuse context information of different scales, enhancing the model’s generalization ability. Compared to the YOLOv5s model, there is a 3.1% improvement in mean average precision (mAP0.5), a 55.8% reduction in model parameters and a 4.8% reduction in giga floating-point operations per second (GFLOPs). These results demonstrate a significant improvement in both accuracy and model parameter efficiency. (Scientific Reports, October 2024, https://doi.org/10.1038/s41598-024-74368-7)

Read full article