July 2024

This issue of PCD&F / CA brought to you by:

PCEA

PO BOX 807

AMESBURY, MA 01913

PCEA BOARD OF DIRECTORS

Stephen Chavez, CHAIRMAN

Justin Fleming, SECRETARY

Gary Ferrari, CHAIRMAN EMERITUS

MEMBERS

Jim Barnes

Michael Buetow

Tomas Chester

Douglas Dixon

Richard Hartley

Matthew Leary

Scott McCurdy

Anaya Vardya

Susy Webb

Eriko Yamato

pcea.net

PUBLICATION

- PCD&F/Circuits Assembly digital.pcea.net

WEBSITES

- PCD&F pcdandf.com

- Circuits Assembly circuitsassembly.com

NEWSLETTER

- PCB Update pcbupdate.com

PODCASTS

- PCB Chat pcbchat.com

EVENTS

- PCB West pcbwest.com

- PCB East pcbeast.com

EDUCATION

- PCB2Day pcb2day.com

- PCEA Training pceatraining.net

- Printed Circuit University printedcircuituniversity.com

AWARDS PROGRAMS

- Service Excellence Awards circuitsassembly.com

- NPI Awards circuitsassembly.com

pcdandf.com

DATABASE

- Directory of EMS Companies circuitsassembly.com

mike@pcea.net

frances@pcea.net

Peter Bigelow, Robert Boguski, John D. Borneman, John Burkhert, Jr., Stephen Chavez, Geoffrey Hazelett, Mark Finstad, Jake Kulp, Nick Koop, Alun Morgan, Susan Mucha, Greg Papandrew, Chrys Shea, Jan Vardaman, Gene Weiner

production@pcea.net

nathan@pcea.net

frances@pcea.net

will@pcea.net

frances@pcea.net

mike@pcea.net

jacqueline@pcea.net

PRINTED CIRCUIT DESIGN & FAB/CIRCUITS ASSEMBLY is distributed without charge to qualified subscribers. To subscribe, visit pcdandf.com or circuitsassembly.com and click on Subscribe.

For changes or cancellations to existing subscriptions: subscriptions@pcea.net

PRINTED CIRCUIT DESIGN & FAB/CIRCUITS ASSEMBLY is published monthly by Printed Circuit Engineering Association, Inc., PO Box 807 Amesbury, MA 01913. ISSN 1939-5442. GST 124513185/ Agreement #1419617.

© 2024, by Printed Circuit Engineering Association, Inc. All rights reserved. Reproduction of material appearing in PRINTED CIRCUIT DESIGN & FAB/CIRCUITS ASSEMBLY is forbidden without written permission.

A Status Plan for Implementing AI Takes Shape

Artificial intelligence as applied to electronics design and manufacturing is in its infancy, but interest is high and questions abound as to what it means – and even what it is.

AI is seen as similar to the Internet in 1995: a big, wide-open technology that companies had to embrace and understand. Success depends on narrow implementations that permit companies to see clearly what the return or improvements will be.

AI holds the potential to revolutionize the creation and manufacturing of electronic products. Unlocking this potential, however, requires collaborative efforts to ensure its effective understanding and implementation. Without concerted action, the realization of AI’s transformative promise in the electronics industry may remain elusive.

READ FULL ARTICLE

NextFlex Launches $5.3M Funding Opportunity for Hybrid Electronics

WASHINGTON – NextFlex, the Department of Defense-sponsored Manufacturing Innovation Institute focused on maturing hybrid electronics, released Project Call 9.0 (PC 9.0) in June, its latest call for proposals that seek to fund more than $5 million in projects that further the development and adoption of hybrid electronics while addressing key challenges in advanced manufacturing.

The total PC 9.0 project value is expected to exceed $11 million (including NextFlex investment and performer cost-share), bringing the total anticipated investment in advancing hybrid electronics since NextFlex’s formation to $143 million.

Building from the success of past Project Calls, PC 9.0 uses broadly defined topics to enable a diverse proposer base, with special emphasis on areas in which hybrid electronics can impact high priority U.S. manufacturing opportunities and areas of emerging importance within the electronics manufacturing community. PC 9.0 emphasizes projects that address critical hybrid electronics manufacturing challenges, enabling the transition of hybrid electronics devices into applications that require superior performance, assured reliability, and improved environmental sustainability.

READ FULL ARTICLEReport: EU Electronics Manufacturing to Continue Decline

BRUSSELS – Despite the adoption of the European Chips Act, the EU’s market share in critical electronics components beyond chips, including PCBs, EMS and advanced packaging, will decline to 15% by 2035, according to a new report.

The Securing EU’s Electronics Ecosystem report finds that the continent’s PCB industry segment has faced significant erosion over the last two decades, and revitalizing and growing electronics manufacturing – beyond chips – is essential to building a secure and robust European electronics ecosystem. A “silicon to systems” approach is necessary to support ongoing EU technological leadership and meet strategic goals.

“An innovative and resilient European electronics manufacturing industry is vital to ensuring the region’s access to defence and aerospace systems, medical technologies, and communications infrastructure. The growing strategic dependencies highlighted in the report are alarming as they undermine Europe’s ability to achieve key strategic priorities from a strengthening of the defense industrial base to the green and digital transitions,” said Sanjay Huprikar, president of Europe and South Asia operations, IPC, which released the report.

READ FULL ARTICLESeacomp Opens Assembly Plant in Tijuana

CARLSBAD, CA – Seacomp in May opened a new 60,000 sq. ft. assembly facility in Tijuana, Mexico.

The new plant features 5,000 sq. ft. of space dedicated to PCB assembly, featuring solder paste printing and inspection, automated SMT placement, and reflow soldering.

“Manufacturing is a global industry, but it’s also a hands-on business,” said CEO Michael Szymanski. “That’s why we’ve made the decision to bring most of our leadership team back together under one roof and introduce a new Seacomp facility just an hour away from our command center in Southern California.”

Read Full ArticleTyri Begins In-House Circuit Board Production in Sweden

KUNGSBACKA, SWEDEN – Tyri, a manufacturer of lighting equipment for work machines, is starting in-house production of circuit boards in Sweden.

The company’s 1,800 sq. m. facility will make Tyri self-sufficient in this area, giving it increased control, higher quality, and more reliable deliveries, the company said.

“We see many advantages in producing the circuit boards we need ourselves. Increased quality and delivery reliability are two of the most important reasons. We will produce for our production facility in Gothenburg and also for our production units in the UK and the USA,” said Jimmy Nordén, factory manager at Tyri Sweden.

READ FULL ARTICLEApple Among New Members of IPC-2581 Consortium

WESTBOROUGH, MA – Apple, Beta CAE and Panasonic Connect were welcomed as the newest members of the IPC-2581 Consortium during the group’s May meeting.

“We would like to support IPC-2581 as a standardized format to enable better communication between, for example, fab and assembly vendors,” Apple said in a statement.

During the meeting, members also discussed the use of a coin shape as an interesting application in a CAD system for PCB design, as well as a new via type to handle the application and how it would be defined in the CAD system. Other topics of discussion included the need for improved communication of materials and stack-up definitions to manufacturers – including composite and roll-up materials, the need to define and name dielectric layers in the stack up, particularly for trench vias, and the inclusion of span information for these layers.

READ FULL ARTICLEDoosan Named CCL Supplier for Nvidia AI Chips

SEOUL – Doosan Electro-Materials is anticipating a boost in copper-clad laminate sales after being selected as CCL supplier for Nvidia’s AI chip substrates, according to reports.

Doosan, the world’s largest CCL manufacturer, recently began mass production for Nvidia’s next-generation GPU B100, which is scheduled to be released in the fourth quarter.

Doosan’s first-quarter sales were 186.5 billion won ($135 million), and are projected to reach 900 billion won this year.

READ FULL ARTICLEFlex Acquires FreeFlow B2B Platform

AUSTIN, TX – Flex has acquired FreeFlow, a company that specializes in global secondary markets and circular economy tracking and reporting.

FreeFlow’s B2B digital marketplace platform enables customers to sell surplus and returned inventory while protecting primary sales channels. Flex said the addition adds services for customers across multiple markets, including data center, enterprise, and lifestyle, to create additional revenue streams and accelerate sustainability through second life products.

“The acquisition of FreeFlow reaffirms Flex’s commitment to deliver the highest value to our customers, addressing their evolving business and sustainability needs across the product lifecycle while increasing our addressable market,” said Michael Hartung, president of Agility Solutions at Flex. “This addition further differentiates our end-to-end services and will enable a wide range of customers, from cloud to lifestyle, to realize the benefits of second life products, and ultimately deliver on their environmental commitments.”

READ FULL ARTICLEASMPT Reorganizes American SMT Business

MUNICH – ASMPT has reorganized its SMT Solutions segment in the Americas (USA, Canada, Mexico and Brazil), adding a new division between the North and South America regions.

The division of the business, which was previously managed centrally from Suwanee, GA, will allow the company to adjust its market focus to better meet the specific needs and requirements of the different markets, ASMPT said in a release.

The company said the markets in Mexico and Brazil differ from those in the US and Canada, with mainstream solutions for the high-volume production of consumer goods, computers and automotive electronics being the main drivers in Mexico and Brazil, while the Canadian and US markets focus on innovative and customer-specific advanced packaging solutions for high-mix production and on the development of special products for medical technology, the aerospace and defense industries, as well as industrial electronics.

READ FULL ARTICLEKeytronic Confirms Data Breach After Ransomware Attack

SPOKANE VALLEY, WA – Keytronic in June began notifying potentially affected parties and regulatory agencies of a breach that saw more than 500GB of personal data stolen.

The EMS company reported the cyberattack in an SEC filing in May, saying that the attack disrupted its operations by limiting access to business applications essential for corporate activities, and its domestic and Mexico operations were shut down for two weeks to address the incident.

Keytronic has resumed normal operations, but an investigation found that personal information had been stolen during the attack, the company said.

READ FULL ARTICLEPCD&F

Amber Enterprises reportedly plans to invest ₹2,000 crore ($239 million) to set up a PCB manufacturing facility in India.

Bittele Electronics completed an expansion and installed improvements at its Markham, ON, PCB manufacturing facility.

BPL set up a new manufacturing unit for printed circuit boards in Bengaluru, India.

Eton Electronics will invest no more than $100 million into a new PCB production base in Thailand.

Jianding will invest $250 million to build a second PCB manufacturing facility in Vietnam.

Read Full ArticleCA

Aaloktronix announced the availability of PCB assembly services tailored for the aerospace industry.

AIM Solder joined the International Electronics Manufacturing Initiative (iNEMI) and announced a distribution partnership with EIS in Mexico.

Altus will distribute PVA’s Delta 6 robotic conformal coating/dispensing system in the UK and Ireland.

BAE Systems won a $95 million contract to supply advanced electronic warfare (EW) pods for the US Navy’s P-8A aircraft.

Beifu Electronic installed Europlacer’s Atom range of pick-and place machines.

Read Full Article

PCD&F

PCBAA named Summit Interconnect CEO Shane Whiteside chairman following the end of Travis Kelly’s term.

Garmin promoted Aaron Parker to technical lead PCB designer.

HT Global Circuits hired Bryan Fish as regional sales manager.

Sanmina named Vishnu Gangaswamy Venkatesh to succeed senior VP Brent Billinger, who is set to retire in January.

TE Connectivity named Ted Shpak global senior director of quality assurance.

CA

AIM Solder promoted Chris Matthews to business development manager for the Americas and appointed Mhanny Aguillo Southeast Asia technical sales manager.

Europlacer appointed Richard Timms international channel manager.

Hanwha Techwin Automation Americas appointed David Suh application engineer.

Heller Industries named Bob Doetzer sales representative for North and South Carolina and Tim Glasgow sales representative in Georgia, Tennessee, Alabama and Mississippi.

Indium Advanced Materials appointed Werner Wagner general manager.

Read full articlePCB East 2024 Registration Up 18% YoY

PEACHTREE CITY, GA – Registration for the PCB East 2024 conference and exhibits rose 18% overall year-over-year, the Printed Circuit Engineering Association announced in June. Conference registration was up 12% from last year, while the expo-only trade show registration rose 9% over the same period.

The exhibition was held June 5 at the Boxboro Regency Hotel and Conference Center in Boxborough, MA. In all, more than 65 leading suppliers of electronics design tools, manufacturers of bare boards and assemblies, suppliers of fabrication and assembly equipment and materials, and related industry companies exhibited at the show.

2025-26 Board of Directors Slate Announced

PEACHTREE CITY, GA – The PCEA Nominations Task Group has chosen three new members to join the board of directors for the upcoming term.

The board in June also voted for Matt Leary and Jim Barnes to join the board, effective immediately, to fill two open positions.

Barnes is corporate senior vice president, strategic global sourcing, at Generac Power Systems, a leading energy technology company. He is an expert in strategic planning, outsourcing, and manufacturing operations, having held a variety of management roles at multinational EMS SigmaTron prior to joining Generac in 2022.

Read Full ArticlePCB East Seeks Abstracts for 2025 Conference

PEACHTREE CITY, GA – The PCEA Conferences Task Group seeks abstracts for next year’s PCB East technical conference.

The conference will focus on training and best practices for printed circuit board design engineers, electronics design engineers, fabricators and assemblers.

The four-day technical conference will take place April 29 to May 2, 2025, in Boxborough, MA. The event includes a one-day exhibition on April 30.

Read Full ArticleGeneral. The annual PCD&F salary survey of printed circuit board designers, design engineers and other layout specialists is open and may be taken at: https://www.surveymonkey.com/r/2024pcdfdesignerssalary. PCD&F publishes the aggregate data in a free downloadable report on its website and in the magazine. Individual responses are not shared.

To find the latest on chapter events, visit https://pcea.net/events.

Boston. We are planning to hold our next meeting in July via Zoom. The chapter has launched a LinkedIn page at PCEA-Printed Circuit Engineering Association – New England Chapter.

Portland. Our June meeting featured a talk on IPC-2581 vs. Gerber and AI in PCB design. We meet monthly, usually by Zoom. Contact Stephan Schmidt at stschmidt@pcea.net for an MS Teams invitation.

India EMS Market Set to Soar

PARIS – India’s domestic electronics manufacturing services revenues are on track to more than double over the next three years, reaching $55 billion by 2027.

That’s according to a report by BNP Paribas, which forecasts investments led by companies such as Apple and Samsung will add significant heft to the nation’s EMS industry.

Apple, the bank’s report says, will increase investment to $40 billion over the next four to five years to boost domestic production capacity of laptops as well as smartphones. Lenovo intends to build servers in support of its growing data center business, while Acer, HP and Nokia are also expected to expand domestic operations. (more)

Hot Takes

First quarter smartphone production grew 18.7% year-over-year to 296 million units shipped, but remained below pre-pandemic levels of over 300 million units. (TrendForce)

Semiconductor exports from China rose at a faster pace in the first five months of the year. (China government)

The expansion of semiconductor fab capacity in 2024 is expected to be 4% as manufacturers let capacity utilization rates recover from the low levels experienced in 2023. (Knometa Research) (more)

Is Private Equity Investing in Your EMS?

Getting a grip on the many moving parts.

Much of my time this decade has been spent supporting private equity (PE) firms considering an investment in the EMS space, with no prior EMS experience on their staff. Those of us who have spent years in this space know there are vast amounts of “moving parts” involved with running a solid EMS business.

I’ve been told that my audits and SWOT writeups proved to be very valuable, provided accurate insight into a business the potential investors knew very little about and reduced previously unknown risks that would have crept into the deals.

Many similarities exist among the audits I’ve conducted over the past few years. Many of these findings would not surprise EMS industry veterans. But these situations may not be self-evident to an investor who hasn’t previously worked in this complex service industry. I have also seen many of these elements of risk at my direct EMS clients managed to different degrees of efficiency.

Read Full Article

PCB Tariffs are All the Rage. They Aren’t the Answer.

Supply chains are stronger when spurred by private investment.

Both the Trump and Biden administrations have taken measures aimed at bringing manufacturing back to the US. But realistically, when will that happen?

And how much longer will we ask domestic PCB buyers who must rely on Asia for product to pay a tax for boards they cannot get made in a reasonable amount of time in the US?

In late May the US trade representative announced one more year of reprieve from the 25% tariff for two- and four-layer rigid printed circuit boards.

Read Full Article

Hybrid Bonding and Thermal Concerns Heat Up Denver Discussions

IEEE’s annual conference of academic and research leaders reveals equipment and process advances.

The heat wave covering much of the Rocky Mountains in June was an apt metaphor for the annual IEEE Electronics Components and Technology Conference (ECTC) in Denver, where some 2,000 attendees heard the latest developments in advanced packaging. Thermal issues were as much a part of the proceedings indoors as out.

The conference in the Mile High City opened with a Heterogeneous Integration Roadmap (HIR) session. Presentations addressed the thermal challenges and specifically called out the needs for developments in metrology focused on thermal measurement. The conversation carried over into a parallel special session on metrology where participants from NIST, ASE, Intel, TSMC and KLA discussed challenges and opportunities in advancing metrology for next-generation microelectronics. The discussion culminated with a call to action to incorporate metrology challenges in every aspect of the HIR moving forward and potential for a future NIST workshop.

Thermal challenges continued to be a hot topic with the special session on efficient and innovative thermal management for power-hungry AI/ML applications featuring presentations from key players. Many papers highlighted thermal challenges and some solutions were discussed. TSMC presented its development of an energy-efficient Si-integrated micro-cooler for high power computing. The Intersociety Conference on Thermal and Thermomechanical Phenomena in Electronics Systems co-located its ITherm conference in the same venue, where a keynote from Nvidia discussed how generative AI and accelerated compute are creating the next-generation liquid-cooled data centers with a focus on challenges, opportunities and the road ahead. Thermal management was a key topic in AMD’s presentation on next-generation AI architectures. Analytics for thermal management of data centers was highlighted by Seguente, UC Irvine discussed fundamentals of machine learning for phase change heat transfer, and NXP provided additional observations on the role of AI in thermal management. IBM Research provided insight on how AI can be used to provide thermal management solutions.

Read Full Article

Getting Flexible

Rigid-flex brings the best – and worst – of both worlds.

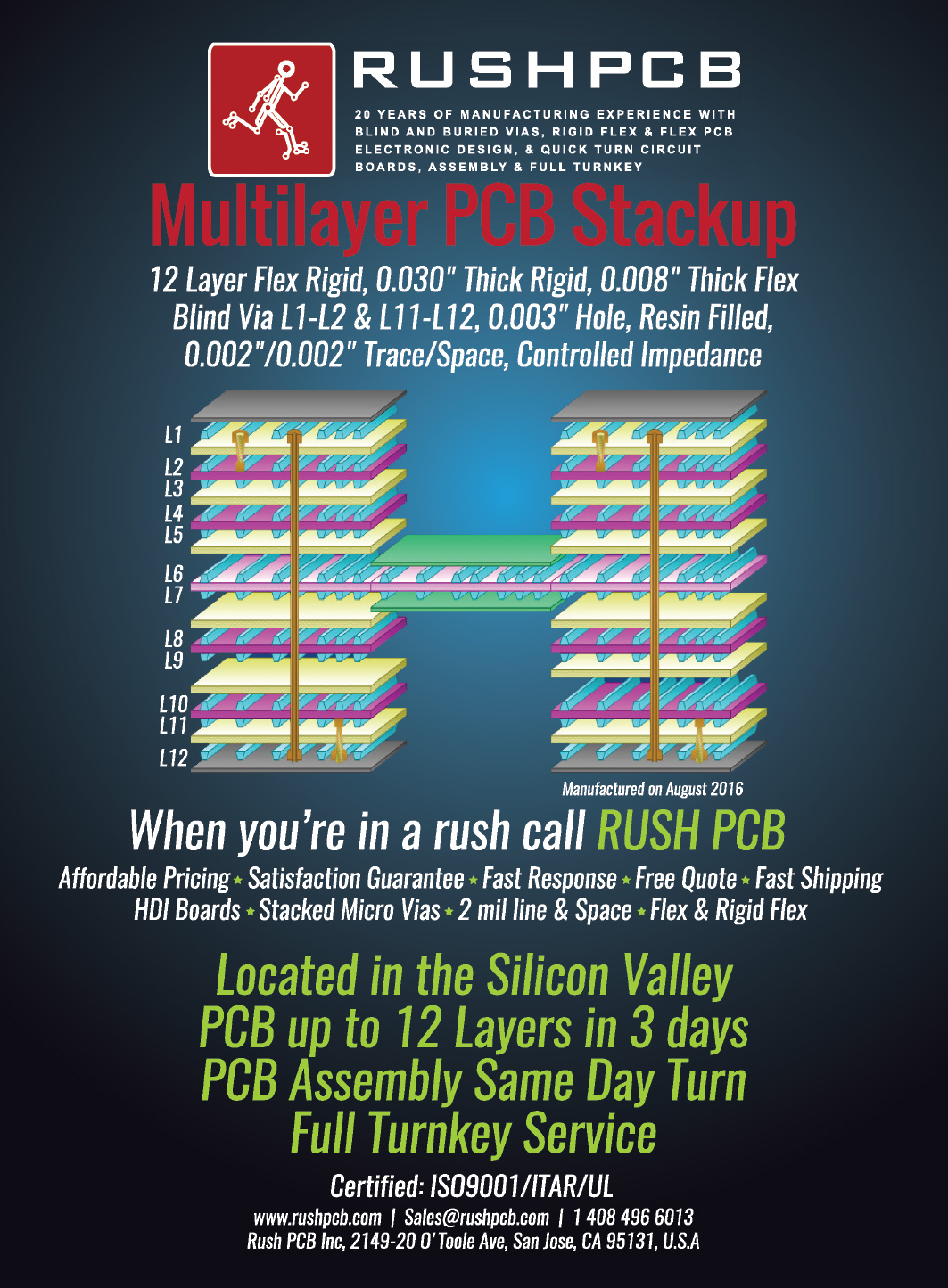

Combining all aspects of a flex circuit with a rigid board that makes full use of HDI techniques is one of the breakthroughs of our time. The stacking connectors for board-to-board or the typical flex circuits are bypassed. If you’ve ever tried to connect a flex circuit to a stacking connector, you know that’s a bottleneck in the process – blindly positioning the flex connector over the mating connector can be fiddly to the point of destroying the connectors. Now what?

Rigid-flex projects remind me of digital/analog projects: the best of both worlds and the worst of both. Just for starters, if the team is taking this route, you know they are serious about holding things together with all possible integration. Both technologies are well understood on their own, though the rigid camp is larger and better understood.

Flex circuits on their own. Flexible printed circuits (FPCs) require more than a change of materials from their stiffer cousins. Additional tolerance must be designed into the data. Reason: The different types of material stacks used in the manufacturing process. For the most part, a flex will also have a rigid section where the connector is mounted. The stiffened area could also be extended to host the ESD protection, an LED or microphone; we’re flexible.

Read Full Article

Talking Points

While AI offers specialized communication skills, it creates new data-storage and security challenges.

Many of us would struggle to grasp the concept of a zettabyte in any practical sense. Mathematically, it’s 1 trillion gigabytes and, between we humans and our machines, we expect to generate more than 180 zettabytes of digital data in 2025. Right now, about 330 million terabytes are being introduced into the world every day – that’s equivalent to the entire US population filling their OneDrive allowance on a daily basis. According to this essay on the World Economic Forum, storing our data will present major challenges: the way things stand, in 100-150 years’ time there will be more data bits than atoms on the Earth and storage will consume more than the total energy generated today.

Problems notwithstanding, our prodigious output is an impressive human achievement. We have progressed through cave paintings, smoke signals, the invention of paper and books, to the many prolific techniques we have available today. It’s all about the drive to communicate and express ourselves, which is embedded deeply in our nature.

Now assisted by AI, we could exceed even our own predictions. With more or less universal access to large-language models like GPT (generative pre-trained transformer), we can produce text at an incredibly fast rate. Text-to-image models like OpenAI’s DALL-E and Google’s Imagen now provide even more powerful tools for creative expression. We can create digital artwork that most of us simply would not have the skills to produce any other way, and in vastly less time than would be needed using traditional media or even manual digital tools. This is incredibly empowering technology that can be used to share ideas, visions and creative passions in more natural and intuitive ways than previously possible. On the other hand, the data mountain is set to grow exponentially.

Read Full Article

Sunny Times at Sunstone Circuits

One year out from its merger with American Standard Circuits, the West Coast fabricator is evolving to meet a changing customer base.

by Tyler Hanes

From its inception as part of Electronic Controls Design in 1972, to its joining with American Standard Circuits last July, Sunstone Circuits has been committed to innovating in the industry – for instance, it is said to be the first to offer online quoting and ordering in the 1990s – as well as providing exceptional customer service.

To better understand what makes Sunstone go, PCD&F visited the company’s 32,000 sq. ft. facility in Mulino, OR, in late April, and took an inside look at its operations.

The company has historically been focused on high-mix, low-volume offerings with an emphasis on quickturns – having around 99% on-time delivery – and quality – with less than a 1% return rate, said vice president and general manager Matt Stevenson.

Read Full Article

‘Everybody is Growing’

The East Coast trade show brings news of a steady industry, while puncturing myths about AI.

by Tyler Hanes

Members of the electronics community gathered in the Boston suburb of Boxborough in early June for the return of PCB East, PCEA’s annual event featuring four days of technical sessions and a one-day exhibition.

This year’s exhibition featured more than 65 companies running the gamut of the PCB industry, from fabrication, design, and assembly to test and inspection, and most of those companies reported steady growth thus far, with small gains over 2023.

For Cadence Design Systems, revenue has continued to grow over the past few years and is up around 15% so far in 2024, said product management director Patrick Davis.

Read Full Article

AI: The Shiny New Tool in the Engineer’s Toolbox

Searching for components and automating schematic capture are just two of the ways AI will be implemented in PCB design.

by David Wiens

During the past 10 years, artificial intelligence (AI) has progressed from a visionary concept to a mainstream reality in many large companies. AI is becoming a crucial lever for improving operational productivity and user expertise.

AI is a set of computational technologies that enable a machine to reason and infer without any human intervention. These technologies are developed using cross-disciplinary approaches based on mathematics, computer science, statistics, and psychology. AI based solutions can analyze high volumes of data to identify trends and patterns which can then be used to improve existing processes and make recommendations to assist users in making better decisions.

System-in-Package and Multichip Module Technology

Moving forward on the ‘More than Moore’ roadmap.

by Yaniv Maydar

We’re witnessing a rapid evolution in advanced semiconductor nodes and market growth due to the meteoric rise of AI, mobile, autonomous automotive, IoT, communications and cloud, health tech, and wearables. The various technologies driving the overall functionality of systems and devices associated with these applications have increased exponentially, impacting factors such as device performance, energy consumption, power dissipation, and space (miniaturization).

Development of the system-on-chip (SoC), combining digital and analog, MEMS and photonic sensors, has led to the small form factors used in smartphones, health monitors, smart homes, and more. Advancements in smaller feature sizes and the resulting billions of transistors per chip translate into increased functionality, enhanced performance, and greater power – but these benefits come at a price. SoCs are hugely complex systems that generate very high NRE costs and involve other budgetary, time, and market constraints. For this reason, it has become clear that alternative technologies are now urgently needed.

The heterogeneous integration of separately manufactured components into a higher-level assembly – system-in-package (SiP) – is able to leverage the advanced capabilities of packaging technology by creating a system close to the SoC form factor but with better yield, lower overall cost, higher flexibility, and faster time to market. A recent paradigm shift from SoC-centric solutions to SiP-centric solutions has occurred, even for high-volume products.

Read Full Article

How to Stay Within the SMT Assembly Process Window

Navigating the balancing act with the application constraints.

by Kevin Pigeon

Understanding and controlling the assembly process window is not just about managing the solder paste. It’s about mastering all process variables across the entire SMT assembly process for optimal outcomes.

The assembly process window defines the range of parameters within which solder paste will meet optimal performance standards. Straying outside this window can lead to defects, rework and inconsistencies, affecting the efficiency and output of the electronics manufacturing process.

These parameters may include acceptable ranges for a number of areas, including but not limited to:

- Total reflow profile time from ambient to peak

- Peak reflow oven temperature

- Time above liquidus

Lean Philosophy and EMS Realities

Non-value activities are sometimes unavoidable.

One challenge for electronics manufacturing services (EMS) providers implementing Lean manufacturing practices can be customer buy-in. While an original equipment manufacturer (OEM) can design a process with minimal non-value-added activity, customer requirements may revive some necessary non-value-added activity and it is up to the EMS provider to find a compromise that satisfies the customer requirements while minimizing the cost of resources associated with the non-value activity.

A recent example of this occurred in SigmaTron International’s Chihuahua, Mexico, facility. A consumer product customer added conformal coating to a product experiencing field failures related to operating environment issues. An automated selective coating machine is used that controls conformal coating deposition areas and application thickness. The customer wanted an automated visual inspection step added to ensure any overspray or missed coating was caught.

From a Lean perspective, the inspection step is a non-value-added process, particularly given the level of spray control associated with the selective coating machine. It was a customer requirement, however. The EMS provider’s team evaluated available off-the-shelf automated optical inspection equipment and found that most had more inspection functions than the customer required and the process cost would exceed the customer’s target price.

Read Full Article

PCD&F

EasyLogix PCB-Investigator V15.1 ECAD

PCB-Investigator V15.1 brings enhanced import/export functions, advanced analysis tools and a more user-friendly interface to streamline the PCB design process. Key features include enhanced import and export functions for various file formats and faster data handling, advanced thermal simulation and improved DfM checks, more UI options and improved reporting tools, and enhanced support for machine formats to streamline manufacturing processes.

EasyLogix

Pasternack Impedance-Matching Pads

Impedance-matching pads for 50Ω and 75Ω transmission lines are said to provide seamless transition between the two types of lines. Ensure optimal performance across a variety of RF applications and feature BNC, F-type, N-type, and SMA connectorized designs, making them versatile for integrating into existing systems with ease. Facilitate 50Ω to 75Ω impedance matching as well as 75Ω to 50Ω, catering to a broad spectrum of transmission requirements. Feature configurations including 50Ω BNC to 75Ω F-type among various gender setups, and combinations like 50Ω N-type male to 75Ω F-type male, and 50Ω SMA male to 75Ω F-type female to solve diverse connectivity challenges.

Pasternack

Stackpole RNWA Thin Film Resistor

Stackpole’s RNWA is a thin -film chip resistor with wide terminations and is capable of tolerances to 0.1% and TCR as low as 25ppm. Is automotive grade, which provides an additional level of long-term stability and reliability as well as being resistant to sulfur.

Stackpole Electronics

CA

ASMPT Siplace CA2 Placement Machine

Siplace CA2 hybrid placement machine combines semiconductor and SMT production to integrate the production of SiPs (system-in-package modules) directly into the SMT line. Processes both SMDs from tapes and dies taken directly from the wafer in a single step at speeds of up to 50,000 dies or 76,000 SMT components per hour with a precision of up to 10µm at 3σ. Features a buffer storage module that works similar to a placement head and can hold 16 new dies (plus four on the flip unit) while the placement head itself is still placing SMDs. Also features full single-die-level traceability, which automatically logs for each die its pick-up and placement position on the board, as well as speedy program and product changeovers, placement program portability to any machine of the same type, and fast and comprehensive substrate mapping.

ASMPT

Aven High-Performance Diagonal Cutters

Aven’s diagonal cutters are crafted for cutting and longevity for a range of industrial tasks. Titanium diagonal cutter is made with high-grade titanium. Features an overall length of 150mm and a semi-flush blade type, an oval head with a 22mm width, and cuts low carbon steel wire up to 1.6mm in diameter and soft copper wire up to 2mm. Features a lightweight design and a comfortable plastic grip to reduce hand fatigue for extended use without discomfort.

304 stainless steel cutter is designed for various cutting applications and offers a semi-flush cutting edge able to cut low carbon steel wire up to 1.6mm in diameter and soft copper wire up to 2mm. Features ergonomic PP+TPR grip to ensure comfort during use, and oval head style and 200mm overall length are said to provide control and leverage.

Aven

In Case You Missed It

Components

“How a Simple Circuit Could Offer an Alternative to Energy-Intensive GPUs”

Author: Sophia Chen

Abstract: On a table in his lab at the University of Pennsylvania, physicist Sam Dillavou has connected an array of breadboards via a web of brightly colored wires. The setup looks like a DIY home electronics project – and not a particularly elegant one. But this unassuming assembly, which contains 32 variable resistors, can learn to sort data like a machine-learning model. The potential energy savings works this way: Digital chips like GPUs expend energy per operation, so making a chip that can perform more operations per second just means a chip that uses more energy per second. In contrast, the energy usage of his analog computer is based on how long it is on. Should they make their computer twice as fast, it would also become twice as energy efficient. While its current capability is rudimentary, the hope is that the prototype will offer a low-power alternative to the energy-guzzling graphical processing unit (GPU) chips widely used in machine learning. (MIT Technology Review, Jun. 5, 2024, https://technologyreview.ae/source/how-a-simple-circuit-could-offer-an-alternative-to-energy-intensive-gpus/)

Read full article