July 2023

PCEA

PO BOX 807

AMESBURY, MA 01913

PCEA BOARD OF DIRECTORS

Stephen Chavez, CHAIRMAN

Justin Fleming, SECRETARY

Gary Ferrari, CHAIRMAN EMERITUS

MEMBERS

Michael Buetow

Tomas Chester

Michael Creeden

Douglas Dixon

Richard Hartley

Scott McCurdy

Anaya Vardya

Susy Webb

Eriko Yamato

pcea.net

PUBLICATION

- PCD&F/Circuits Assembly digital.pcea.net

WEBSITES

- PCD&F pcdandf.com

- Circuits Assembly circuitsassembly.com

NEWSLETTER

- PCB Update pcbupdate.com

PODCASTS

- PCB Chat pcbchat.com

EVENTS

- PCB West pcbwest.com

- PCB East pcbeast.com

EDUCATION

- PCB2Day pcb2day.com

- Printed Circuit University printedcircuituniversity.com

AWARDS PROGRAMS

- Service Excellence Awards circuitsassembly.com

- NPI Awards circuitsassembly.com

pcdandf.com

DATABASE

- Directory of EMS Companies circuitsassembly.com

mike@pcea.net

frances@pcea.net

brooke@pcea.net

tyler@pcea.net

jacqueline@pcea.net

Clive Ashmore, Peter Bigelow, Robert Boguski, John D. Borneman, John Burkhert, Jr., Stephen Chavez, Mark Finstad, Geoffrey Hazelett, Nick Koop, Geoffrey Leeds, Alun Morgan, Susan Mucha, Greg Papandrew, Chrys Shea, Jan Vardaman, Gene Weiner

frances@pcea.net

brooke@pcea.net

frances@pcea.net

mike@pcea.net

jacqueline@pcea.net

PRINTED CIRCUIT DESIGN & FAB/CIRCUITS ASSEMBLY is distributed without charge to qualified subscribers. To subscribe, visit pcdandf.com or circuitsassembly.com and click on Subscribe.

For changes or cancellations to existing subscriptions: subscriptions@pcea.net

PRINTED CIRCUIT DESIGN & FAB/CIRCUITS ASSEMBLY is published monthly by Printed Circuit Engineering Association, Inc., PO Box 807 Amesbury, MA 01913. ISSN 1939-5442. GST 124513185/ Agreement #1419617.

© 2023, by Printed Circuit Engineering Association, Inc. All rights reserved. Reproduction of material appearing in PRINTED CIRCUIT DESIGN & FAB/CIRCUITS ASSEMBLY is forbidden without written permission.

Some Thoughts for Summer

Random thoughts as the summer kicks in:

• Is anyone surprised the Foxconn investment in Lordstown Motors has run out of gas? It was an odd marriage in many ways – the world’s largest ODM buying up the assets of a failing Midwestern automaker – but Foxconn took a similar approach with Sharp and, from a technical perspective, it gained crucial knowledge in electric vehicles, which it likely will need to keep its hooks in Apple, its biggest and most important customer, which almost assuredly is developing its own vehicle as a platform for its future software products.

Lordstown is now suing Foxconn over the breakup. Critics, on the other hand, are noting the long line of Foxconn promises that failed to materialize as planned and suggesting this was all too predictable.

• Speaking of Apple, the cellphone, and more precisely, the smartphone, may be the greatest consumer invention in the past 100 years. It’s certainly among the most ubiquitous. About 68% of the world’s citizens have smartphones, which given a global population of about 8.05 billion, suggests some 2.58 billion or so people are still walking around without an electronic device glued to their hands. (Bully for them.) While that means a huge market remains to be captured, the market share has been steady-state for the past five years.

READ FULL ARTICLESchmid Group Aims for Listing on NYSE

FRANKFURT – Schmid Group plans to list in New York via a special purpose acquisition company (SPAC) in a deal estimated to give the technology firm a valuation of $640 million.

The fifth-generation family-owned business, which specializes in electronics, would become a publicly listed company on the New York Stock Exchange in the fourth quarter this year.

The transaction will be through blank-check company Pegasus Digital Mobility Acquisition Corp. led by Ralf Speth, the company said in a statement.

READ FULL ARTICLEAT&S Celebrates Plant Construction Milestones

LEOBEN, AUSTRIA – The exterior shell of AT&S’ new R&D and IC substrate center here has been erected just 14 months after groundbreaking, and the company’s new plant in Kulim, Malaysia, has also reached a significant milestone with the completion of the facility’s construction and installation of the first systems.

When complete, the company’s €500 million ($537 million) plant in Leoben will include 11,000 sq. m. of clean room production area, and the gross floor area is 39,000 sq. m. (420,000 sq. ft.).

Once the project is complete in 2024, the facility will be the first in Europe to produce IC substrates – essential for future-oriented applications in microelectronics.

READ FULL ARTICLEElement Solutions Acquires Copper Nanotech Developer

MIAMI, FL – Element Solutions in June announced the acquisition of Kuprion, a developer of nano-copper technology for the semiconductor, circuit board and electronics assembly markets.

Kuprion’s ActiveCopper technology addresses effects of thermal expansion in a host of growth applications, including electric vehicles, high frequency 5G networks, IC substrate manufacturing, advanced packaging, mission-critical aerospace and defense systems, and datacenters.

Element Solutions, the parent of MacDermid Alpha Electronics Solutions, said the acquisition has been structured with an upfront payment and potential earn-out payments based on milestones associated with product qualification and revenue over several years.

READ FULL ARTICLEAltair Survey Finds Friction Points for Enterprise AI and Data Projects

TROY, MI – A survey by Altair found high rates of adoption and implementation of organizational data and AI strategies globally, but also found that project successes suffer due to three main types of friction: organizational, technological, and financial.

“Organizations today recognize the imperative of using their data as a strategic asset to create competitive advantages,” said James R. Scapa, founder and chief executive, Altair. “But friction points clearly exist around people, technology, and investment preventing organizations from gaining the data-driven insights needed to deliver results. To achieve what we call ‘Frictionless AI,’ businesses must make the shift to self-service data analytics tools that empower non-technical users to work easily and cost-effectively across complex technology systems and avoid the friction inhibiting them from moving forward.”

READ FULL ARTICLEZhen Ding Building $700M Headquarters in Taiwan

TAOYUAN, TAIWAN – Zhen Ding will invest 5 billion yuan ($701 million) to build a 14,000 sq. m. green energy headquarters here.

The new facility will be located near the Taoyuan Qingpu High-Speed Railway Station and will be the new home for the PCB maker. Zhen Ding has been the global leader for PCB production for the past six years, and Taoyuan’s PCB production value accounts for 29% of the world’s total production and 84% of Taiwan’s.

Zhen Ding chairman Shen Qingfang said the company has been expanding its production capacity in mainland China due to the unavailability of suitable land in Taiwan, but the new headquarters will permit the company to make an investment in his hometown of Taoyuan.

“The establishment of the Taiwanese headquarters will enable easier employee travel to and from major production bases, improve communication between the group’s plants, increase investment in various plant areas in Taiwan, and encourage related supply chain manufacturers to cluster together for greater efficiency,” he said

Ventec to Build New Factory in Southeast Asia

SUZHOU, CHINA – Ventec International announced plans to open a new manufacturing facility in Southeast Asia by 2025/26 to extend its manufacturing capabilities beyond China and Taiwan and enhance global supply chain resiliency.

The new factory will duplicate manufacturing capability for Ventec’s full range of high-reliability and high-performance products and mitigate supply chain risks for PCB manufacturers, OEMs and EMS companies across all regions by adding geographical diversity to the company’s operations, Ventec said in a release.

“Now is the right time to invest in establishing a local manufacturing presence to support the expanding southeast Asian electronics industry, which is experiencing significant growth across

consumer, industrial, and automotive sectors,” said Ventec CEO Jason Chung. “Moreover, this new factory will enhance our global supply chain security promise to our global PCB and OEM customer base as we plan to manufacture the complete portfolio of advanced high-reliability and high- performance materials.”

Aohong Electronics Commits $84M to Thai PCB Plant

CHANGZHOU, CHINA – Aohong Electronics has announced plans to spend as much as 600 million yuan ($83.7 million) building a new PCB fabrication plant in Thailand.

The project, set to be constructed in an industrial park in the Prachin Buri province, will be built in phases and aim for mass production to start in 2026, the company said.

Aohong has two production bases in China with a total annual output of 4 million sq. m. of PCBs for home appliances, consumer electronics, power sources, network communications, and vehicle electronics for clients that include LG Electronics, Whirlpool and General Electric.

The Prachin Buri project will enhance Aohong’s core competitiveness by better serving existing and potential key clients and lowering production costs, the company added.

Icape Group Acquires German PCB Distributor HLT

FONTENAY-AUX-ROSES, FRANCE – Icape Group has acquired the operating assets of HLT, a German PCB distributor that generated revenue of €4.1 million ($4.4 million) in 2022.

HLT, based in Baden-Württemberg, a state known for its automotive industry, supplies PCB to around 50 well-known customers in various sectors, such as automotive, home automation, telecommunications, aerospace and medical. HLT has a network of six strategic suppliers and its own logistics capabilities, providing a range of high value-added services in high-mix low-volume markets.

The acquisition was carried out by the subsidiary Icape Deutschland GmbH and is financed 100% in cash.

In a release announcing the acquisition, Icape Group said HLT’s operating assets will strengthen its position as a leading player in one of the major markets for PCB distribution in Europe and worldwide. The acquisition will also consolidate and optimize the global network structured by Icape Group, offering a significant value creation potential.

READ FULL ARTICLESiemens Allocates $2.2B in New Manufacturing Capacity

MUNICH – Siemens will invest €2 billion ($2.2 billion) to expand its manufacturing in Asia, including a new plant in Singapore and a capacity expansion at a factory in China, to meet rising demand in the region.

In Chengdu, the conglomerate will spend up to €140 million to expand the site, which makes factory automation products. Likewise, the Singapore investment of €200 million result in a new facility for producing factory automation devices.

ECIA GIPC Launches 2-D Barcode Review

ATLANTA – ECIA’s Global Industry Practices Committee has launched a five-year review of its 2-D Barcode Specification, which published its last revision in 2018 to continue guiding the industry on the use and value of this technology for product identification labeling.

Concurrent with the publication of the specification, ECIA launched new initiatives to promote the use of this technology throughout the electronic component channel, and over the past decade, there has been widespread adoption, substantially improving the efficiency of the end-to-end order process.

READ FULL ARTICLEJEDEC Publishes Major Update to JEP30 PartModel Guidelines

ARLINGTON, VA – JEDEC Solid State Technology Association has announced significant updates to the JEP30 PartModel Guidelines, including all reference documents and related XML Schema files. JEP30 and its constituent documents are available for free download from the JEDEC website.

JEP30 establishes requirements for the frictionless digital exchange of part data between part manufacturers and their end customers responsible for electrical and electronic products creation. The JEP30 guidelines define a standardized format that can be efficiently consumed across different CAD tools and environments. By defining a common framework for part model creation and verification and helping to ensure different tools can accurately interpret and utilize the models created by the full spectrum of part manufacturers, JEP30 offers a transformative resource for both component manufacturers and designers.

READ FULL ARTICLENew PCB Assembler Launches in Quebec

QUEBEC – Fabrique Manic, a provider of PCB assembly services has opened here. Located in St-Augustin-de-Desmaures, just outside of Quebec City, the company was founded by two colleagues from the tech industry.

Dominic Gauvreau, president – electronic design and assembly, and Olivier Morin, vice president – business development, aim to deliver solutions that alleviate complexities and delays of the physical product production cycle. The firm offers electronic design and consultation, and manages rapid prototyping, including three-day turnarounds (upon receipt of parts). PCB- related assembly services include mechanical assembly, firmware programming, board modifications and more.

READ FULL ARTICLEIncap Inaugurates 3rd Factory in India

TUMKUR, INDIA – Incap recently celebrated the opening of a new 26,500 sq. m. factory in India – its third in the country.

The Tumkur factory specializes in manufacturing electronics and box-build products, and features machinery suitable for common component technologies. Together with its location and skilled personnel, the company can provide high-quality manufacturing services to meet the most demanding customer needs, Incap said.

“Looking ahead, the EMS industry holds a promising future,” said Otto Pukk, president and CEO. “Therefore, we maintain our dedication to investing actively in our operations and fostering their development. I would like to express my sincere gratitude to our exceptional team in India whose collective efforts have played a crucial part in establishing our new factory.”

READ FULL ARTICLERapid Manufacturing Unveils Kulim Expansion

KULIM, MALAYSIA – Rapid Manufacturing has announced a new facility here to serve the aerospace, telecommunication, medical, semiconductor, automotive and industrial automation sectors, as well as house a regional center to set up a center of excellence.

The company made the announcement in a joint statement with the Malaysian Investment Development Authority (MIDA) and the Northern Corridor Implementation Authority (NCIA).

Rapid Manufacturing subsidiary RPD MFG Connectivity managing director Yogendran Krishnamurthy said the company’s investment is expected to create an estimated 2,000 jobs locally, including at least 500 high-income jobs.

READ FULL ARTICLEEscatec Builds New Production Facility in Bulgaria

PLOVDIV, BULGARIA – Escatec has opened a new production facility here to meet an increasing demand for nearshoring production in Europe.

The 4,000 sq. m. facility is already operational to vertically integrate plastic molding and electronics assembly to support the company’s production commitments in Europe, and Escatec said it is willing to expand capacity and capabilities at this new facility as order volumes pick up.

“Escatec Bulgaria is an important new site in Escatec’s portfolio as we move to complete our global manufacturing footprint. Customers of Escatec can expect that we deliver a best-value solution, regardless of region, as we continue to harness the benefits of our multi-site strategy,” said Charles- Alexandre Albin, Escatec’s executive director and director of strategic development.

READ FULL ARTICLECompal Building New Vietnamese Plant

THAI BINH PROVINCE, VIETNAM – Compal Electronics has purchased a $30 million plot of land in Vietnam to build a new plant and expand production capacity.

The Taiwanese firm’s Vietnamese subsidiary leased a 40-hectare plot in the Lien Ha Thai Industrial Park in Thai Binh province, Compal said in a stock exchange filing. Compal is already producing Apple products in Vietnam, with factories in Vinh Phuc, on top of its major production sites in China’s Chongqing and Jiangsu as well as Thailand’s Phetchaburi, according to Apple’s latest supplier list.

Ekkaa Electronics Shifting to Consumer Electronics Production

SONIPAT, INDIA – Ekkaa Electronics has announced plans to build a new factory in Noida, India, that will produce LED TVs and other consumer electronics products like washing machines, smartwatches and hearables.

The company said it will be investing INR1,000 crores ($122 million) in the new manufacturing unit, and the construction of the facility will mark a shift for the company from assembly to core manufacturing of consumer electronic products. With the growing demand for exports out of India, Ekkaa will soon launch an export arm as well.

READ FULL ARTICLEPCD&F

Dynamic Electronics has accelerated the construction of its new plant in Thailand, which is scheduled to open in the fourth quarter of 2024.

Mitsubishi Gas Chemical will expand production capacity of BT laminates for semiconductor substrates at its Thailand campus.

Nan Ya released its plans for setting up factories in Southeast Asia between the end of the third quarter and the fourth quarter at the earliest.

Northern Copper announced plans to issue Series A shares to raise 1 billion yuan ($140 million) to increase PCB-related projects.

RBP Chemical Technology announced a strategic partnership with Mid-States Graphics to expand its product offerings.

Taiwan PCB Techvest announced plans to set up a new plant in Vietnam to produce PCBs for optoelectronics and notebook applications.

TSMC is reportedly contemplating a 3% to 6% price increase for its advanced process manufacturing beginning in January 2024.

Xinxing is actively deploying new products involving AI and is working closely with Intel’s data center division to meet the demand for AI servers.

CA

Adco Circuits purchased a Hänel Lean-Lift vertical storage system and a Scienscope Reel Smart incoming material station, installed a new robotic thermal adhesive dispenser, and launched ADCOproto.com – an online tool that provides instant component availability for uploaded BoMs.

Advantex installed and commissioned a Milestone IP surveillance system along with a number of high-resolution Axis IP cameras at Plexus.

AIM Solder appointed ACD Renaissance manufacturers’ representative in India.

Cetec ERP was chosen by GoldStar Medical Instruments to provide a web-based

solution for inventory control, traceability, accounting and quality management.

Dixon Technologies said it is partnering with Xiaomi’s Indian arm to make and export phones for the Chinese Xrm.

Firearm OEM FN Herstal is now offering contract assembly at its primary manufacturing facility near Liege, Belgium.

Read Full ArticlePCD&F

Patrick Sandberg

Kathy Carron

Shavi Spinzi

Con$dee appointed Patrick Sandberg sales manager Germany.

Freedom CAD Services named Kathy Carron account manager.

Nano Dimension promoted Shavi Spinzi to VP AME and PCB technologies.

CA

Nolad Neva

Rolando Andrade

AIM Solder appointed Nolan Neva regional sales manager for the US west coast.

Ametek named Rolando Castillo Andrade engineering manager.

Ark Electronics appointed Thierry Basse to manage its new European oGce in Bordeaux, France.

Cyklos Materials appointed Anandkumar R. Kannurpatti CEO and cofounder.

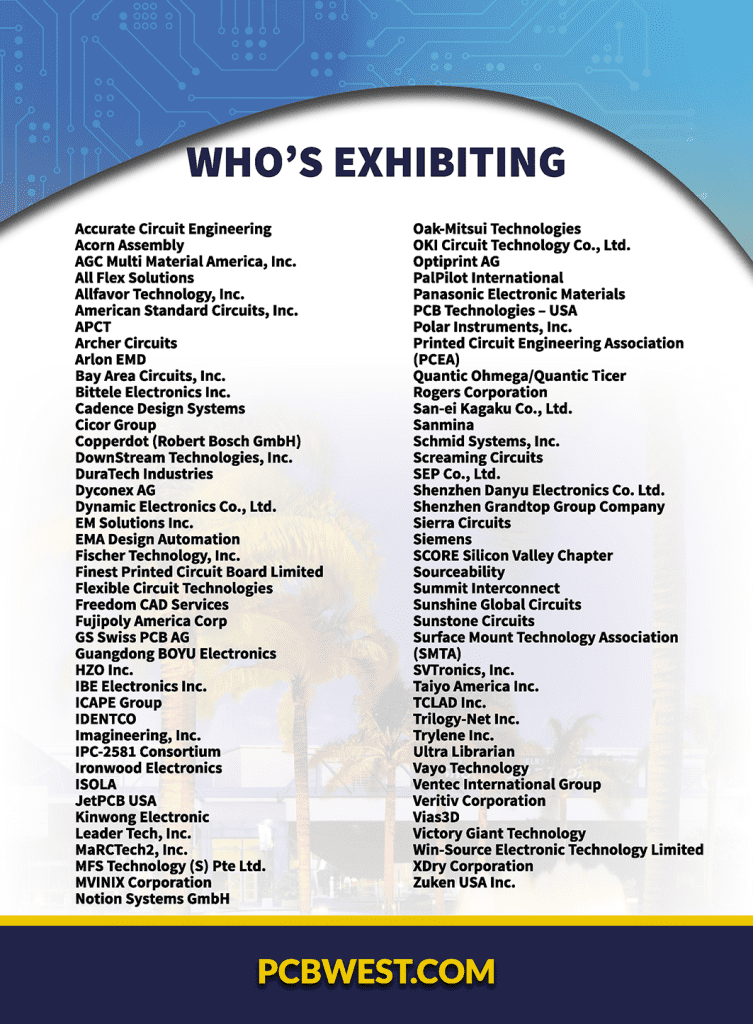

Read Full ArticlePCB West Registration Now Open

PEACHTREE CITY, GA – The Printed Circuit Engineering Association has opened registration for the technical program for PCB West 2023, featuring nearly 50 presentations and more than 130 hours of in-depth electronics engineering training.

Among the industry experts on tap for this year’s show are Lee Ritchey, Susy Webb, Tomas Chester and Zachariah Peterson.

The conference will be held Sept. 19 to 22 at the Santa Clara (CA) Convention Center and features classes for every level of experience, from novice to expert.

Read MoreChapter News

Education committee. The committee is reviewing the overview of free content that is available at pcea.net, with feedback due in June. This project is being managed by John Watson.

The committee is also updating the 2023 PCD&F Salary Survey prior to distribution to the membership.

Troy Hopkins, a senior hardware designer with Connect Tech, has been named chair of the Conferences task group.

Rio Grande Valley. The RGV Chapter had its first public meeting on June 1. We are planning our next meeting for September and will have more details as we get closer.

Supply Chain Productivity Declines Cannot be Solved by Robots and AI Alone, Gartner Says

New technologies ranging from smart robotics to actionable AI have the potential to transform the supply chain function, but they will fail to lift historically low levels of labor productivity unless utilized as part of a broader strategy, according to research firm Gartner.

“There is legitimate excitement today around new technologies that hold out the promise of vastly enhanced organizational productivity,” said Thomas Pocock, senior director, advisory, in Gartner’s Supply Chain Practice. “Supply chain leaders must remember that these new technologies require the partnership of an engaged and productive workforce for these gains to be realized. Unfortunately, the data tell a discouraging story on this front.”

Pocock highlighted data from a first quarter Gartner survey when 2,613 supply chain employees were surveyed to show the extent of supply chain’s labor productivity challenges:

READ FULL ARTICLEWill We Demand a New Supply Chain?

And will capital equipment makers stay put, relocate or – shudder! – exit the business?

IN MANY WAYS, the past three years have seemed very much like a dream, with life shifting from normal to masked panic and social distancing, to light at the end of the tunnel, to where we mostly appear to be now: back to normal! But while most faces are uncovered, businesses have taken down Plexiglas separating cashier from customer, and retail floors have only a few faded “stand here” decals visible on the floors, not all is truly back to normal.

Geopolitical strains have developed in Asia and an unprovoked war is taking place in Europe. Both series of events – combined with the pandemic – put unprecedented strains on a global supply chain that for decades relied upon political stability and free access to countries around the globe. While the pandemic focused most of us on the here and now, it also caused companies – and countries – to pivot on where and how they source product.

For North America, the lack of certain technologies, many central to our industry’s ability to produce technology-rich products, became glaringly obvious and made many in industry and government even more concerned. That concern led directly to the CHIPS Act, which in time will certainly help alleviate some supply-chain issues in North America, although it is not a short-term panacea. For the rest of the world, however, strains will persist and possibly get far worse.

Read Full ArticleAdvanced Packaging: The Hot Topic in the Florida Sun

ECTC revealed the latest developments in 3-D hybrid bonding.

MORE THAN 50 presentations on hybrid bonding filled rooms to capacity at the IEEE Electronics Components and Technology Conference (ECTC) in Orlando, as did the Tuesday morning panel session. That panel discussion (FIGURE 1), on “Copper Hybrid Bond Interconnections for Chip-to- Wafer Applications,” organized by Infinera and Qualcomm and moderated by TechSearch International, included perspectives from design and EDA (Synopsys) and research institute IMEC, users of hybrid bonding (AMD with production at TSMC and Intel with its internal development program), equipment makers Besi and EVG, and yield and reliability specialist PDF Solutions.

Thermoelectric Cooling on Printed Circuit Boards

TECs can be a countermeasure to high current density.

THERMOELECTRIC COOLING, OR TEC, is seen as a breakthrough in small refrigerators that do not consume a lot of power. Sporting goods stores carry micro-fridges that plug into a car’s weird circular power plug. Some of us – not me, of course – can remember when those plugs were used to create a glowing hot element to light cigarettes. Getting cold out of the same socket took a little more technology than creating a short circuit.

Where would you use a TEC device? Aside from keeping a six-pack (or a transplant organ) on ice, electronics can be kept at a reasonable operating temperature with the addition of a component or a cold plate like the one in FIGURE 1. It is 40mm square and 3.2mm thick. The basic function is that it gets cold on one side while getting warm on the other. Put it in the other way to warm up the contents. This can be placed below the board or above the high load component if it has a flat top. More remote placement is possible by incorporating a heat spreader. We’ll circle back to that shortly.

Read Full ArticleDesign and Manufacturing Collaboration

Clear communication with manufacturers can ease that queasy feeling.

YOU ARE FINALLY finished with that very complex monster of a printed circuit board (PCB) design while enduring a very tight project schedule. Now it’s time to get the design data to manufacturing for fabrication and assembly, but there is a lingering doubt in the back of your mind, an uneasy feeling in the pit of your stomach as you hand off data to manufacturing. Why? I’ll explain, based on my perspective gleaned from decades of designing PCBs.

Let me start with a question: Did you collaborate with your manufacturing suppliers up front? The answer for many is typically “No!” You may have simply designed a PCB without any manufacturer involvement whatsoever, generated output files and threw the data over the proverbial wall to the manufacturer in hopes that what you designed is buildable and will work as intended. Then, when a technical query (TQ) hits your inbox, you might get upset and wonder why you’re being notified that the job is on hold because the design data contain issues or are missing information that needs to be addressed before fabrication can begin. In some cases, it’s not just answering with a reply of “approved to modify as suggested,” but rather it requires going back and redesigning! Sadly, this happens in our industry far too often, and in more instances than you would expect.

Read Full ArticleData Overload

AI could be the key to understanding the data collected by the IoT.

BIG DATA IS useless and all the sensors in the world are not enough. Contentious? Maybe. I’ve talked in the past about the prospects for digitizing the world and it’s true that we have many of the ingredients to make this happen: tiny, low-power sensors including optical and MEMS inertial sensors that provide contextual awareness; connectivity technologies for almost every practical and budgetary constraint; low-cost processing power and mass storage.

We’re well on the way to seeing almost 30 billion devices connected to the IoT in the next couple of years, and there is no practical limit to this. We have enough IPv6 addresses to cover the earth’s surface many times over with smart “things.” We can easily collect the data we need to digitize the world.

The bigger challenge is to understand what that data are telling us and, from there, determine suitable responses. The sheer volume, velocity and variety of data we can now capture through IoT devices easily exceed the capacity of humans to analyze and extract meaningful insights manually. AI is the perfect companion to the IoT, capable of providing the assistance we need. Bringing them together as the AIoT is the key to tackling complex challenges such as sustainability. Studying the climate and humans’ impact, the effects of using natural resources such as energy, and the prospects for controlling and managing these are subject to huge numbers of variables that are impossible for us to analyze effectively.

Read Full ArticleThe AI Revolution is Coming to PCB Design

System-driven part selection and routing are closer than ever.

IT’S RARE FOR a motivational keynote speaker to have a lasting impact on attendees. At Zuken Innovation World’s US iteration in June, however, Dan Thurmon certainly set the pace for the conference. The author of Off Balance on Purpose and a popular Ted Talk on embracing uncertainty, Thurmon’s address had attendees referencing and even reenacting portions of his opening presentation in their subsequent presentations. The motivational speaker helped set an energetic and educational tone for the conference that followed.

And thanks to the coming AI revolution, uncertainty is what’s ahead.

Zuken Innovation World is a series of conferences around the world dedicated to bringing customers, partners and Zuken experts together. A good portion of the eight concurrent training tracks at the June event in Scottsdale, AZ, was dedicated to sessions led by customer-users sharing design best practices and success stories. Surprisingly for a conference dedicated to a specific supplier, there was never even a hint of sales; this was a full-on conference dedicated to networking and educating, where one could learn about upcoming technologies, best practices, and novel implementations of toolsets that only a user would discover. At times, it was overwhelming to decide which of the concurrent sessions to attend, as multiple competing interesting presentations were occurring!

Read Full ArticleGD&T and PCBs

Don’t mix your units.

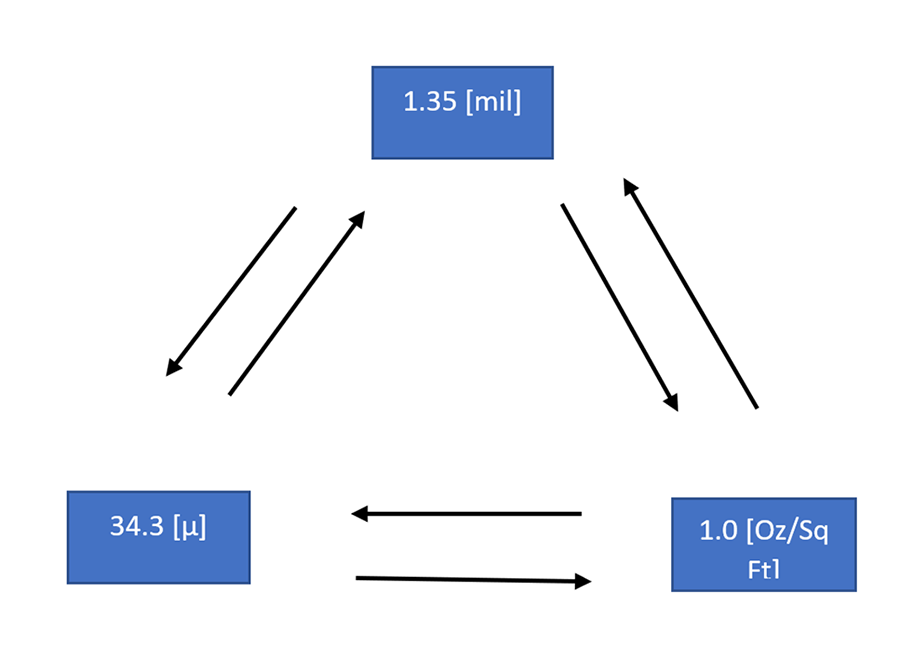

WHEN I FIRST started in the PCB fabrication industry, I was fresh from college and ready to jump in and make an impact. The first hurdle I hit was likely the same as many first-time designers: units of measure for PCB design. Remember back in school, your physics professors or science teachers likely pointed out missing units in tables, graphs or homework assignments? That problem.

In PCB design and fabrication, at least in the US, three common ways are used to describe the relative thickness of a PCB layer. At this point in my career, I’m not going to fight about which should be the industry default (just kidding: it’s microns. Get with the metric system America!). I am only going to take issue with consistency. If you mix units on a print or fail to tolerance them properly, you are going to have a bad time. By bad time, I mean waste time, money and make the print more confusing and difficult to manufacture. Let me explain.

Read Full Article‘We Teach the Engineering of PCB Design’

For students at Palomar Community College, a 4nely-tuned design curriculum is just the beginning.

by MIKE BUETOW

It goes without saying that finding talent is a big deal in electronics hardware development. Outside of internal training programs, talent development falls to the handful of colleges, universities and third parties involved in teaching printed circuit design and manufacturing.

One of the original providers is Palomar College, located in San Marcos, CA, part of San Diego County. The community college has offered practical printed circuit design coursework since the mid-1990s.

John Watson’s day job is customer success manager at Altium. But twice a week during the school year, he teaches the course on printed circuit design at Palomar. He spoke with us in May for the PCB Chat podcast. This transcript of that interview is lightly edited for length and clarity.

Read Full ArticleRightsizing Continuous Improvement Focus

Match the resources that make sense in the scale of your operation.

by MATT CLINE

In the early 1990s, some observers were predicting that the EMS market would consolidate and shrink to a handful of large players building the bulk of the world’s electronics products. But outsourced electronics manufacturing isn’t a one-size-fits-all equation. Even large OEMs often have higher mix, lower volume or variable demand segments of business that fit best in a regional EMS provider. Consequently, regional EMS providers continue to thrive.

That said, just as different types of manufacturing projects are often best served by different tiers in the EMS industry, regional EMS companies often need to right-size internal processes to match the resources that make sense in that scale of business. One area that can benefit from this rightsizing approach is quality management and continuous improvement.

While similar ISO quality management system frameworks make sense regardless of company size, the types of metrics collected, the size of the dedicated quality staff and the methodologies in place to drive corrective action do benefit from a more tailored approach.

Read Full ArticleKey Considerations When Selecting a Replacement Vapor Degreaser Cleaning Fluid

Can your preferred choice be dropped in?

by ELIZABETH NORWOOD

Let’s set the scene. You have been using the same vapor degreasing fluid to successfully clean complex circuitry and printed circuit boards (PCBs) for years, only to learn that your trusted line of cleaning fluids will soon be discontinued. What do you do? How do you choose a replacement that meets the PCB cleaning challenges that you and many other fabricators face?

Factors to consider when choosing a replacement cleaning fluid include the equipment, the substrate being cleaned, the type of contamination being removed, the long-term availability and sustainability of the replacement fluid, and the level of support available from the supplier.

Taking these factors into consideration, PCB manufacturers can make an informed decision and select a replacement cleaning fluid that meets their specific needs while minimizing any negative impact on their cleaning processes.

Read Full ArticleUnderstanding Criticality of Thermal Performance in Thermal Interface Material Applications

Effects of types of TIM types, thicknesses and contact pressure in a real-world application.

by Dr. Rita Mohanty

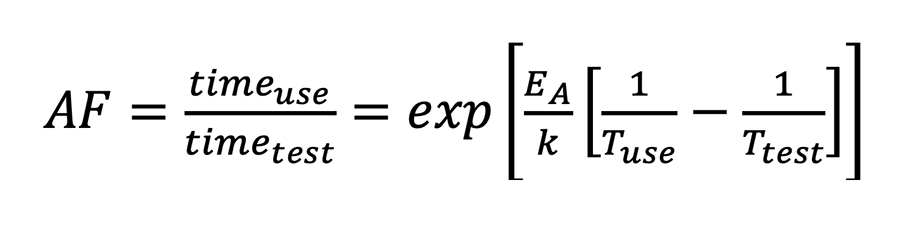

Power electronics are integral parts of power components, power supplies, 5G networks, automotive and defense/space applications. All modern power electronics have two critical factors in common that drives the need for unprecedented thermal management: first, increased transistor density to meet the higher demand in increased computing power and second, component miniaturization leading to higher heat flux. It is well known in the electronics reliability field that 55% of the component failures in electronics devices are related to excess heat. The Arrhenius equation in Eq. 11 predicts that, for electronics, the lift of the device decreases by half2 by increasing the device temperature by 10°C. Design engineers mitigate this issue by carefully selecting thermal interface materials (TIM) to keep the system/device temperature at the desired level.

AF = Acceleration factor

T = Temperature

EA = Activation energy

K = Boltzmann constant

The primary function of a TIM is to replace the air between the heat-generating component and the heat spreader/heatsink to improve heat dissipation. FIGURE 1 shows an illustration of a typical microelectronics packaging assembly with heatsink and TIM. Unevenness and roughness of the surface must be taken into consideration when implementing a thermal solution.

Read Full ArticleThe Visual Factory and Legacy Equipment and Processes

MES upgrades capture kanban inventory levels, allowing electronic replenishment pulls.

THE VISUAL FACTORY has come a long way since the concept was introduced, moving from production status viewable by walking the factory floor to a comprehensive collection of real-time data viewable from any interconnected computer. That evolution isn’t seamless for many electronics manufacturing services (EMS) providers, however. While newer equipment platforms are designed to integrate with manufacturing execution systems (MES) easily, legacy equipment platforms may require specialized programming or other workarounds to achieve desired interoperability. Equipment communication incompatibilities often lead to multiple shop floor control systems being utilized among work areas, which is inherently inefficient.

SigmaTron International’s Chihuahua, Mexico, facility recently dealt with these issues when the facility began transitioning to the company’s proprietary Tango MES. The company’s corporate IT and operations teams have worked together to define enhanced shop floor capabilities in production and are upgrading system capabilities across facilities. The challenge for facilities implementing the latest enhancements is creating efficient equipment interfaces and integrating or replacing legacy processes.

Read Full ArticleCourtship of a Tech Bro

Bluster, manipulation and gaslighting – all in a week’s work.

“… 90 PERCENT OF the startups founded by dweeby young men in San Francisco are simply trying to answer the question: ‘What things isn’t my mom doing for me any more?’ Creating a frictionless future seems to mean launching speedy meal delivery, dog walking, and laundry apps. ‘There is a tendency in Silicon Valley to want to be revolutionary without, you know, revolutionizing everything …’ Too many moonshots are still sputtering on the launch pad. It is not yet clear that innovations such as social media, cryptocurrencies, or the metaverse yet represent any net positive for humanity. As skeptical economists never tire of pointing out, the digital revolution has so far had little quantifiable effect in lifting productivity.”

“Money talks, but it doesn’t tell the truth.”

– John Thornhill, Financial Times

“Time heals all wounds, right up to the moment that it kills you.”

– Herbie Cohen

And still they come.

Read Full Article

PCD&F

ALTAIR SIMULATION 2022.3 SOFTWARE

Simulation 2022.3 brings updates that focus on cloud collaboration and computing, end-to-end simulation workflows, and design creation with AI-powered simulation. New features include updates to Altair One that eliminate data silos, IT constraints and access barriers, as well as new seamless digital thread work=ows that connect Altair One and Altair HyperWorks for previewing and modifying models, tracking data, accessing online libraries, and more. New features also include eGcient end-to-end simulation workflows to Altair HyperMesh, Altair Inspire and Altair SimLab. Enables users to utilize Inspire Fluids to create, modify, and change part and assembly shapes that meet hydraulic design objectives, and Inspire now supports the Linux user interface and offers a new set of geometry creation tools. Also includes electronic system design improvements that give users the power to perform battery module modeling and thermal analysis of complex electronic systems with greater eGciency. AI-powered simulation also enables users to better capture expert decision-making for improved design-of-experiments outcomes, and expanded integration for creating general links among variables of any type and create responses from external file types.

Altair

ALTIUM 365 GOVCLOUD STORAGE

Altium 365 GovCloud offers organizations the features and advantages of the Altium 365 cloud platform, along with additional security measures customized for highly regulated industries. Can help organizations manage regulated product development, meet flow-down requirements as contractors and suppliers, maintain strict control over access to their IP, and reduce IT overhead while meeting regulatory requirements such as ITAR and EAR. Features the ability to prevent unauthorized outbound traGc from leaving the environment using an outbound proxy, disables sharing outside of the workspace, prevents users from storing any data in their Altium 365 Personal spaces, and blocks connections to third-party PLM systems. Also features the ability to allow inbound access to the workspace only for authorized IP addresses, plus blocks access to the workspace from outside the US.

Altium

CA

CIRCUITMEDIC 201-7100 REWORK TOOL SET

201-7100 Precision Surface Mount Rework Tool Set includes nine Onely crafted tools for precision repairs on circuit board assemblies. Crafted to meet the demands of modern electronics, this toolset is designed to help perform intricate repairs, ensuring the longevity and optimal performance of electronic devices. Caters to every aspect of circuit board repair, rework, and assembly. Are built to withstand rigorous use in demanding environments. Comes with a specially designed metal mesh storage tray for easy access, organization and portability.

CircuitMedic

HENKEL BERGQUIST HI FLOW THF 5000UT TIM

Bergquist Hi Flow THF 5000UT phase change Olm TIM permits low mechanical pressure to achieve thorough wet out and an ultra-thin bond line at the interface. Is for challenging package designs with complex architectures, such as lidless multi-chip devices used in high-performance compute and industrial applications. Demonstrates low thermal impedance across various bond line thicknesses at both ultra-low and higher pressure (0.04°C-cm2/W at 35psi, 0.06°C-cm2/W at <10psi), delivers excellent reliability as evaluated up to 150°C, and achieves thermal conductivity up to8.5W/m-K. Provides heat sink suppliers with no-mess, easy application and integrators with simple Onal assembly, and Olm medium – as opposed to liquid materials – permits application before shipment. Does not require pre-burn before use.

Henkel

In Case You Missed It

Nanoprinting

“An All-in-One Nanoprinting Approach for the Synthesis of a Nanofilm Library for Unclonable Anti-Counterfeiting Applications”

Authors: Junfang Zhang, et. al.

Abstract: Current materials for anti-counterfeiting labeling typically contain toxic inorganic quantum dots and the techniques to produce unclonable patterns require tedious fabrication or complex readout methods. Here the authors present a nanoprinting-assisted flash synthesis approach that generates fluorescent nanofilms with physical unclonable function micropatterns in milliseconds. This all-in-one approach yields quenching-resistant carbon dots in solid films, directly from simple monosaccharides. Moreover, the authors establish a nanofilm library comprising 1,920 experiments, offering conditions for various optical properties and microstructures. The authors produce 100 individual physical unclonable function patterns exhibiting near-ideal bit uniformity (0.492±0.018), high uniqueness (0.498±0.021) and excellent reliability (>93%). These unclonable patterns can be quickly and independently read out by fluorescence and topography scanning, greatly improving their security. An open-source deep-learning model guarantees precise authentication, even if patterns are challenged with different resolutions or devices. (Nature Nanotechnology, June 2023, https://doi.org/10.1038/s41565-023-01405-3)

Read full article