May 2023

PCEA

PO BOX 807

AMESBURY, MA 01913

PCEA BOARD OF DIRECTORS

Stephen Chavez, CHAIRMAN

Justin Fleming, SECRETARY

Gary Ferrari, CHAIRMAN EMERITUS

MEMBERS

Michael Buetow

Tomas Chester

Michael Creeden

Douglas Dixon

Richard Hartley

Scott McCurdy

Anaya Vardya

Susy Webb

Eriko Yamato

pcea.net

PUBLICATION

- PCD&F/Circuits Assembly digital.pcea.net

WEBSITES

- PCD&F pcdandf.com

- Circuits Assembly circuitsassembly.com

NEWSLETTER

- PCB Update pcbupdate.com

PODCASTS

- PCB Chat pcbchat.com

EVENTS

- PCB West pcbwest.com

- PCB East pcbeast.com

EDUCATION

- PCB2Day pcb2day.com

- Printed Circuit University printedcircuituniversity.com

AWARDS PROGRAMS

- Service Excellence Awards circuitsassembly.com

- NPI Awards circuitsassembly.com

pcdandf.com

DATABASE

- Directory of EMS Companies circuitsassembly.com

mike@pcea.net

frances@pcea.net

brooke@pcea.net

tyler@pcea.net

jacqueline@pcea.net

Clive Ashmore, Peter Bigelow, Robert Boguski, John D. Borneman, John Burkhert, Jr., Mark Finstad, Nick Koop, Alun Morgan, Susan Mucha, Greg Papandrew, Chrys Shea, Jan Vardaman, Gene Weiner

frances@pcea.net

brooke@pcea.net

frances@pcea.net

mike@pcea.net

jacqueline@pcea.net

PRINTED CIRCUIT DESIGN & FAB/CIRCUITS ASSEMBLY is distributed without charge to qualified subscribers. To subscribe, visit pcdandf.com or circuitsassembly.com and click on Subscribe.

For changes or cancellations to existing subscriptions: subscriptions@pcea.net

PRINTED CIRCUIT DESIGN & FAB/CIRCUITS ASSEMBLY is published monthly by Printed Circuit Engineering Association, Inc., PO Box 807 Amesbury, MA 01913. ISSN 1939-5442. GST 124513185/ Agreement #1419617.

© 2023, by Printed Circuit Engineering Association, Inc. All rights reserved. Reproduction of material appearing in PRINTED CIRCUIT DESIGN & FAB/CIRCUITS ASSEMBLY is forbidden without written permission.

A NewCo to Revive the Past

It’s been well established by now that North America, once neck-and-neck with Japan for the title of largest producer of printed circuit boards, has long since ceded that space to China.

But there was a moment, several years ago, at an industry meeting where market research was broadly disseminated and debated, where Taiwan was promoted – briefly – as the future.

Walt Custer, the charismatic pundit known for his informative and humorous presentations, was asked if North America was about to be eclipsed by the Pacific Rim. His reply was that he felt it was only a matter of time before Taiwan became the top-producing nation.

Dr. Hayao Nakahara, sitting in the audience, then stood and pointed out some basic facts:

- Taiwan had a population of around 23 million.

- China had a population of well over 1 billion.

Biden Invokes Defense Production Act for PCB Production

WASHINGTON, DC – President Joe Biden has authorized the use of the Defense Production Act to spur domestic and Canadian production of printed circuit boards, citing the technology’s importance to national defense.

A presidential determination signed by Biden in April permits the Department of Defense to utilize its Defense Production Act Title III authorities to invest $50 million in advanced microelectronics capacity and ensure the production of state-of-the-art integrated circuits in the US.

“United States industry cannot reasonably be expected to provide the capability for the needed industrial resource, material, or critical technology item in a timely manner,” Biden said in a memo released by the White House. “I find that action to expand the domestic production capability for printed circuit boards and advanced packaging is necessary to avert an industrial resource or critical technology item shortfall that would severely impair national defense capability.”

READ FULL ARTICLEEmerson to Acquire National Instruments

ST. LOUIS – Emerson Electric in April announced it will be acquiring National Instruments for $8.2 billion. The agreement comes after NI rejected multiple offers from Emerson, which initially offered $7 billion.

The transaction is expected to close in the first half of Emerson’s fiscal 2024, subject to the completion of customary closing conditions, including regulatory approvals and approval by NI shareholders.

NI, which provides software-connected automated test and measurement systems, had $1.66 billion in 2022 revenue and operates in more than 40 countries, serving approximately 35,000 customers across semiconductor and electronics, transportation, and aerospace and defense markets.

READ FULL ARTICLEIPC CTC Calls for IC Substrate Manufacturing Facility in US

BANNOCKBURN, IL – The establishment of a pilot facility in the US for manufacturing IC substrates is a first step towards re-establishing semiconductor packaging within the US, and the CHIPS and Science Act of 2022 can be used to jump start the effort, according to a white paper released by the IPC’s Chief Technologist Council.

After decades of offshoring for the PCB and IC substrate industry, the experience base in implementing and executing the operational management of an IC substrate fabrication facility is nearly nonexistent in North America – for both the leadership skills required as well as the process engineering expertise which provides the backbone of these operations, the paper states. No real “surplus” of PCB manufacturing expertise is available to seed an IC substrate fabrication facility, and this is amplified by the fact that PCB companies are generally risk-averse.

While the CHIPS Act is meant to jump start the effort, the competition for funding has led to the proposed creation of complicated, highly centralized mechanisms that are likely to eat up funding while failing to address the underlying needs.

READ FULL ARTICLEWild River Technology and Cadence Collaborate to Improve Simulation Measurement

HILLSBORO, OR – Wild River Technology and Cadence in April announced a collaboration to improve simulation to measurement correspondence using WRT’s next-generation Channel Modeling Signal Integrity Platform.

Cadence chose WRT’s CMP-50 Advanced Channel Modeling Platform for benchmarking its Clarity 3D Solver against the associated EM correlation across multiple workflows and is inclusive of WRT’s 400-800 gigabit Ethernet simulation solution for designing critical interconnects for PCBs, IC packages and systems on IC (SoIC).

CMP-50 incorporates critical structures for material identification in 3-D for anisotropic materials, crosstalk analysis in the x-y and z directions, and a host of additional interconnect solutions that typically challenge EM solvers. This generation improves launch and via design methodology along with crosstalk analysis and changes the trajectory of traditional EDA development often conducted in a hardware- and measurement-less vacuum.

READ FULL ARTICLEAltair Establishes $1M STEM Scholarship at Columbia University

TROY, MI – Altair has established a $1 million scholarship for students pursuing a four-year engineering or STEM-related undergraduate degree at Columbia University’s School of Engineering and Applied Science.

The Altair #OnlyForward scholarship will award 10 students with $25,000 annually, which they will receive each year of their undergraduate studies until graduation.

“Sponsoring these life-changing scholarships is an honor for Altair,” said James R. Scapa, founder and chief executive, Altair. “Throughout our history we have always prioritized diversity, as it is a foundational pillar of our culture and thereby our success. The Altair #OnlyForward Scholarship was established to celebrate and develop the next generation of diverse, world-class talent that will impact our world for years to come.”

READ FULL ARTICLEAPCT Acquires San Diego PCB

SANTA CLARA, CA – APCT has announced the acquisition of San Diego PCB, a printed circuit board design services company. Financial terms were not disclosed.

“We are delighted to partner with San Diego PCB to provide our customers with a complete PCB lifecycle solution from design and layout to prototyping and production,” APCT CEO Steve Robinson said in a statement. “Over the past 20 years, San Diego PCB has built a strong reputation for quality, service and efficiency and is the perfect complement to APCT products. I am delighted to welcome everyone on the San Diego PCB team to the APCT family.”

“We are tremendously excited to join the APCT platform,” said Tony Bell, division manager of San Diego PCB. “APCT shares our dedication and commitment to putting the customer first and is an ideal partner for San Diego PCB. Through this combination, we’ll continue to provide our customers with best-in-class PCB design services, and we’re excited to leverage APCT’s quick turn prototyping and production fabrication capabilities to serve even more of our customers’ needs.”

San Diego PCB merged in 2003 with Milwaukee Electronics.

Sunshine PCB Acquires Vision Industries

SHENZHEN, CHINA – Sunshine Global Circuits has announced the acquisition of Malaysian PCB manufacturer Vision Industries. Closing of the acquisition is subject to government and regulatory approval and is expected to be finalized in May.

The acquisition is meant to extend Sunshine’s manufacturing capabilities into Southeast Asia and enhance Sunshine’s product offerings in microwave and RF circuit boards, as well as further establish Sunshine Global Circuits as a premier international PCB manufacturer after the establishment of Sunshine USA in 2011 and the acquisition of Sunshine Germany in 2013, the company said in a release.

“This acquisition will allow Sunshine and Vision to integrate our capabilities and services to enable us to better serve our customers world-wide,” said Mark Zhang, president and chairman of SGC. “With this acquisition as the starting point, Sunshine will gradually increase the technology and production capability in Penang. We will add HDI process, advanced automation, and quick turn prototyping to elevate the current capabilities while maintaining our high-mix, low-to-medium volume model. Sunshine will devote the necessary resources to scale the Penang facility to be the best manufacturer in Southeast Asia for Rigid and RF PCBs.”

Infinitum Gains PCB Fab Capability with Circuit Connect Acquisition

AUSTIN, TX – Electric motor OEM Infinitum has acquired Circuit Connect, a printed circuit board fabricator based in Nashua, NH, for an undisclosed amount.

In a press release, Infinitum said the acquisition of Circuit Connect supports its efforts to become more vertical and immediately permits a substantially higher production capacity of PCB stators. The acquisition of the 30-year-old PCB fabricator also provides a framework for continuous volume growth, which is critical to meeting the high demand for Infinitum’s electric motor technology.

Circuit Connect has supplied Infinitum with PCB stators for more than five years and has been closely involved in developing the manufacturing process and quality product. The company has 21 employees who will join the Infinitum family, while continuing to service existing customers via the operation from Nashua.

READ FULL ARTICLEWus Takes Over Majority of PCB JV with Schweizer

SCHRAMBERG, GERMANY – Wus Printed Circuits has approved the acquisition of a majority stake in Schweizer Electronic (Jiangsu), increasing its share of the printed circuit board fabricator to 70% from approximately 13%.

Wus also plans to carry out a capital increase of around EUR29 million at the joint venture in China, in which Schweizer Electronic AG will not participate. Schweizer will hold around 20% of the JV when the transactions are closed.

The JV will continue to operate under the name Schweizer Electronic. Under the new majority structure Schweizer Electronic will retain a seat on the board.

Schweizer, which generates almost 30% of its consolidated sales through its JV for high-frequency PCBs, has also agreed to significantly expand its cooperation with Wus. It retains its flagship printed circuit board fabrication plant in Schramberg, with a focus on ensuring high production volumes of chip embedding technology, while also having full access to the technologies of the other Wus plants. In addition to sites in Germany, Taiwan and China, the company plans to expand in Thailand.

READ FULL ARTICLEJabil Building Production Facility in Croatia

ST. PETERSBURG, FL – Jabil has announced the construction of a new production facility in the Croatian city of Osijek. Construction of the new facility is planned to be completed in 2024, and the factory will create more than 1,500 jobs for local workers, the company said in a press release.

The company said it is also planning to open a factory to produce medical prosthetic parts, plus printed circuit assemblies for the automotive industry.

Recruitment has begun and will continue through 2023.

Tempo Automation Announces Acquisition of Optimum Design Associates

SAN FRANCISCO – Tempo Automation announced that it has entered into a definitive agreement to acquire Optimum Design Associates, an electronic design services company with offices in the US and Australia.

By vertically integrating electronic design and manufacturing, Tempo expects to be able to engage with customers even earlier in their product design process, streamlining the hardware development journey and providing a more efficient and faster way to get electronic products to market, the company said in a release announcing the acquisition.

Tempo said the anticipated benefits of the acquisition include access to Optimum’s experienced engineering team and cross-selling opportunities to expand the customer base. The transaction is expected to close in the second quarter of this year.

READ FULL ARTICLEDoE Announces $50M in Smart Manufacturing Incentives

WASHINGTON, DC – The US Department of Energy has announced $50 million in funding from the Bipartisan Infrastructure Law for states to accelerate the use of Smart Manufacturing technologies through providing access to tools and assistance.

The State Manufacturing Leadership Program is meant to remove existing barriers that prevent innovative, data-driven tools and technologies from being used by small- and medium-sized manufacturers (SMMs). These tools will allow SMMs to increase production efficiency and play key roles in bolstering the domestic manufacturing base.

“Unlocking the potential for small- and medium-sized clean energy manufacturing facilities to use the same technologies as larger facilities will make us more competitive on a global scale,” said US Secretary of Energy Jennifer M. Granholm. “This funding opportunity will ensure that the benefits of a clean energy economy are felt across the country.”

READ FULL ARTICLEFoxconn Plans $800M Investment in Southern Taiwan

TAIPEI – Foxconn is planning to invest T$25 billion ($820 million) in the next three years in new manufacturing facilities in southern Taiwan to support its electric vehicle ambitions, the company said in early April.

Foxconn, which is seeking to diversify its revenue base by expanding into the EV market, said the investments in Kaohsiung will include plants for making electric buses and batteries for EVs.

Ocutrx Acquires Spectrum AMT

IRVINE, CA – Medical manufacturing company Ocutrx Technologies has announced the acquisition of Spectrum Advanced Manufacturing Technologies, a Colorado-based electronics manufacturing and assembly company.

With the acquisition, the consolidated Ocutrx Spectrum company now has seven SMT lines, including ISO Optics Lab capabilities, to serve medical, commercial and government entities. Spectrum is known for providing high-relability hardware and NPI support to its customer base, with a history of more than 25 years for many defense, NASA and commercial space flight programs.

Ocutrx said the acquisition will fuel its efforts to repatriate its supply chain and leverage Spectrum’s infrastructure to produce its medical headsets in compliance with FDA standards on US soil. The company will also work with Spectrum’s clients like Lockheed-Martin, Raytheon, Honeywell, Northrop Grumman, Honeybee Robotics, Barber-Nichols and NASA to enable growth opportunities in new non-medical verticals including the aerospace, robotics, 5G, 5G-MEC, automotive, gaming and AR/XR defense markets.

READ FULL ARTICLENote Acquires ATM Electronics

STOCKHOLM – Note has added a second plant in Eastern Europe through the acquisition of Bulgarian electronics manufacturer ATM Electronics.

In a release announcing the acquisition, Note said it expects that the demand for electronics manufacturing in Europe will continue to develop strongly in the coming years, and the SEK36 million ($3.5 million) purchase of ATM Electronics is meant to meet that growing demand. Note also plans to grow ATM’s manufacturing while also increasing its offerings to customers to include complete PCBAs and turn-key products.

“Note continues to develop strongly. We are enthusiastic about this acquisition, which, in addition to adding another profitable plant to the group, also expands our manufacturing capacity in Eastern Europe,” said Johannes Lind-Widestam, CEO and president, Note. “We see great value in the fact that we are now expanding the possibilities to offer our existing customers advanced electronics manufacturing in a very cost-effective part of Europe.”

READ FULL ARTICLEISC Buys MX Electronics Plant in CA

SANTA ANA, CA – Interconnect Solutions Company, a provider of electromechanical and interconnect solutions, announced on Apr. 20 that it has acquired the Santa Ana-based assets of MX Electronics Manufacturing.

In a statement announcing the acquisition, ISC said the addition of MX Electronics’ assets adds capacity in many existing business lines, plus capability in printed circuit board assembly (PCBA) to better serve both existing and future customers. ISC is part of Tide Rock’s manufacturing portfolio.

“We are thrilled to be able to continue serving customers of MX Electronics just up the road from where they’re used to,” said Mark Papp, president, Tide Rock YieldCo. “This acquisition is a natural fit for our company. It will add important capabilities to our shop and allow us to provide our customers with even greater value.”

PCD&F

AT&S said it will delay the start of production at its new plant in Malaysia to 2026-27 due to high market inventory and weak demand.

Fraunhofer-Gesellschaft purchased a Nano Dimension DragonFly IV 3-D printer.

Haier plans to invest Rs 1,500 crore ($184 million) over the next two years to set up a PCB manufacturing and injection molding plant at its Greater Noida industrial park.

Hushi Electronics began construction on a $280 million PCB factory and warehouse in Thailand.

Read Full ArticleCA

Cogiscan announced new distribution partnerships with MacTech for technical sales support and representation in Argentina.

Collins Aerospace plans to expand its electronics production facility in Cedar Rapids, IA, to meet increasing demand.

Ducommun has entered into a definitive securities purchase agreement to acquire BLR Aerospace.

EMD Electronics will spend $300 million to expand its specialty gas production facility in eastern Pennsylvania in a step state officials hope will boost the area’s appeal to the fast-growing semiconductor industry.

Read Full Article

PCD&F

Westermo Network Technologies named Ciro Blazevic PCB layout engineer.

Rogers named Michael Webb senior vice president and chief administrative officer.

CA

Jua Coates

brian laney

gayle sheppard

Richard Dutton

Adam Szychowski

Jennie Tran

Rebecca Mahoney

AIM Solder appointed Demétrius Nunes Maciel to technical support Brazil and Jua Coates to customer service supervisor for AIM Solder Rhode Island.

Alert Tech SMT announced Brian Laney’s promotion to the role of chief operating officer.

Bright Machines announced that Gayle Sheppard will transition from co-CEO to chief executive officer.

Green Circuits named Richard Dutton, CFO, appointed Adam Szychowski, vice president, sales & marketing, and appointed Jennie Tran to senior director of human resources.

Intervala named Sara Fenimore director of supply chain and welcomed William Hibbs and Laura Bradbury as purchasing managers.

MicroCare named Rebecca Mahoney senior quality control chemist.

PCEA Partners with SCORE.org to Provide Business Mentoring

Mentorship is a key reason why PCEA exists, and to that end we are pleased to announce a new partnership with SCORE.org. What follows is from Phil Marcoux, a member of the PCEA Education Committee and a mentor at the Silicon Valley Chapter of SCORE.

PCEA is more than an international network of engineers, designers, fabricators, assemblers, and anyone related to printed circuit development. It also is a network of businesses employing all those involved in printed circuit development and assembly.

The mission of PCEA is to promote printed circuit engineering as a profession by encouraging and facilitating the exchange of information and the integration of new design concepts through education, certification, communications, seminars, and workshops. PCEA is also striving to help its member companies thrive and succeed.

SCORE.org has the mission of fostering vibrant small business communities in the US through mentoring and education. SCORE was created in 1964 and is funded, in part, through a cooperative agreement with the US Small Business Administration. It is committed to help every person succeed in their small business!

Read MoreNational News

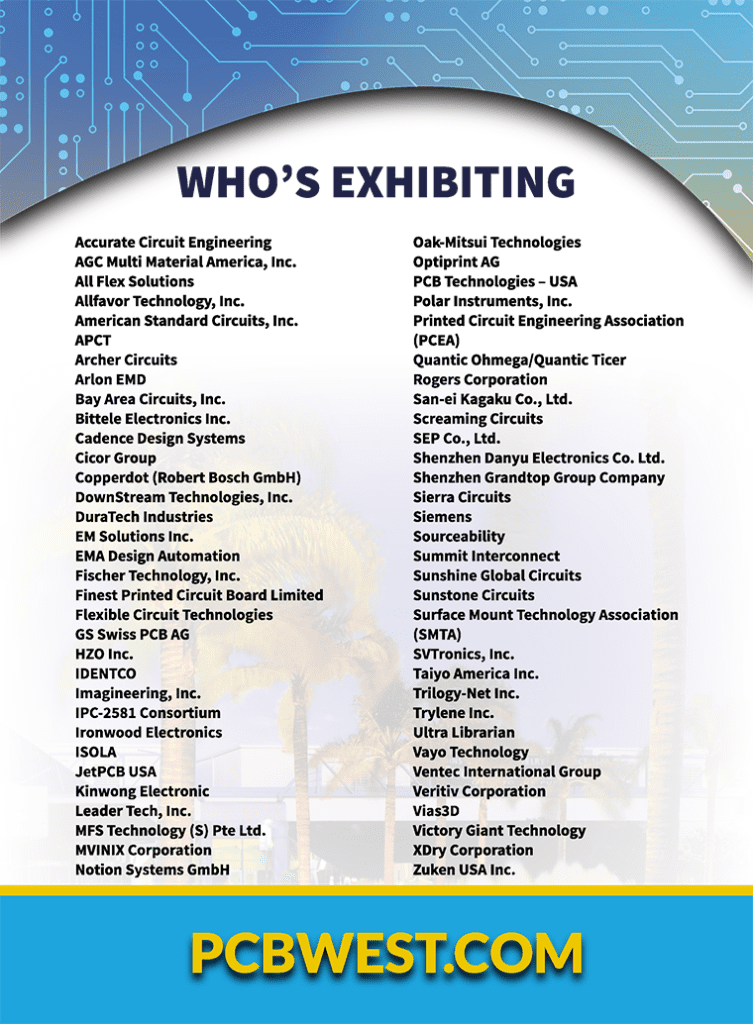

Conferences Task Group. The PCB West 2023 technical conference schedule is available this month at pcbwest.com. This year’s conference features more than 125 hours of top-rank training from the leading names in electronics design and manufacturing. Visit pcbwest.com for details.

EMI seminar. Rick Hartley will present a special live two-day workshop on “Control of EMI, Noise and Signal Integrity in High-Speed Circuits and PCBs,” coming June 20-21 to the Atlanta suburb of Alpharetta. As Hartley notes, EMI is a leading concern for electronics designers and a major cause of failures. The seminar has been updated to contain a fair amount of new information that was not taught in years past. Each attendee will receive a color PDF copy of the full slide deck. For details, visit pcb2day.com.

Read MoreChapter News

Ontario, Canada. We will hold an event in early May with Ata Syed of PFC Flexible Circuits presenting on flex design.

San Diego. We had booth at the Del Mar Electronics Show in San Diego on Apr. 26-27. More than 60 people attended our talks by Mike Konrad of Aqueous Technologies on cleaning no-clean solders and Dave Lackey of American Standard Circuits on flex design and manufacturing.

Seattle. We are looking at getting the Seattle Chapter back up and running. If anyone is interested in assisting with the chapter activities, please contact Tim Mullin at tim_mullin@comcast.net.

Report: PCB Industry in Midst of Down Cycle

COLD SPRING HARBOR, NY – Global PCB sales will fall this year before recovering in 2024, according to new market research from Prismark Partners. Industry sales will be $78.4 billion, down 4.1% from last year, and the average annual compound growth rate will be 3.8% from 2023 to 2027, the firm says.

The firm expects a slowdown this year in each of the major PCB categories: rigid, flex circuits, HDI, and IC substrates. The downturn could be short-lived, however, with demand recovering by later this year.

The data are skewed, says the Taiwan Printed Circuit Board Association (TPCA), due to rapid growth of the substrate segment over the past few years. Lower demand in 2023 will result in a “significant decline” this year for BT and ABF substrates.

READ FULL ARTICLEJapanese PCB Output Continues Slide

TOKYO – Japan’s PCB production continued to shrink in January and recorded the largest decrease in more than six years, with flexible circuit production falling for the third consecutive month, according to the latest statistics released by the Japan Electronics Packaging Circuits Association.

Japanese output of printed circuit boards in January fell by 11.7% from the same month last year to 80.4 million sq. m., with output decreasing 10.7% to 49 billion yen ($375 million).

The output of rigid PCBs in the country fell 8.3% from the same month last year to 679,000 sq. m. in January, shrinking for the 11th consecutive month; the output value fell 11.4% to 29.3 billion yen ($224 million), decreasing for the fifth consecutive month.

READ FULL ARTICLE

The Thrill of the Journey

Remember to sell the excitement of the industry.

As finding and hiring talent has become so difficult over the past several years, it seems in every conversation I have, especially when younger people are involved, the subject turns to the need for talent in the world of manufacturing. With the baby boomers retiring in record numbers and the millennial generation showing so little knowledge of, or interest in, manufacturing, while appearing to prefer a “gig” type of employment (read: it’s just a temporary job), my mantra of talking about the needs of industry for new talent at times seems like a broken record.

Recently a millennial asked me a simple question: “Why do you like manufacturing so much?” The question caught me off guard, for two reasons. First, I assume that everyone knows why I like manufacturing and our industry so much. Second, it’s exactly what needs to be asked, but is typically missing from discussions when seeking and finding new talent! We discuss the need to hire, but rarely do we discuss the excitement, opportunity and personal satisfaction that can be had in manufacturing. Here’s what makes manufacturing, electronics and our industry such an exciting place to be.

Manufacturing means building a tangible product. I like the satisfaction of being part of a team that is making – building – something, something that can be seen, used, and results in a productive object. In retail, you may meet many people, but you did not create anything. In the service sector, you may solve a problem, but not by creating an elegant device. In manufacturing you get to work with people while solving a problem – by building something that can be seen and held!

Read Full Article

There is No Such Thing as a Bad EQ

Proper fab specs can prevent a deluge of engineering questions.

I have been selling bare printed circuit boards for over 30 years to a variety of customers who order a wide selection of PCBs. The most common complaint I hear from board buyers is about the number of engineering questions (EQs) asked whenever a new order is placed, or when a part number is moved from one supplier to another.

“Why can’t you build the boards without all these questions?” they ask. “We sent you the working files!”

To many buyers, the inevitable EQs that come along with moving a PCB order to a more cost-effective supplier seem daunting. Sure, the new pricing may be great, but many PCB buyers will delay switching to a new supplier because they don’t want to deal with engineering questions from the new fabricator.

I hate EQs just as much as the next sales guy. Who wants to bring up a problem or concern to possibly scare a customer or delay an order over what might seem a minor issue? But it is business malpractice when buyers are knowingly leaving money on the table because they don’t have the time or knowledge to properly order PCBs from better suppliers just because of potential EQs.

Read Full Article

PCB Design in a Chip Company: Some Significant Particulars

To land the job you want, it pays to be grounded and groomable.

Starting a new job is a big deal even if you’re not leaving your current company. It’s a commitment to learn the ropes while being humble and deferring to those in the know. In the field of PCB layout, a lateral move is often as good as moving up if the move expands your skill set in a way that helps your long-term goals.

Long-term goals should be about more than money. What is your dream company? What is the role that would keep you engaged or become a step toward the top rung of your personal career ladder? My niche is in wireless. Once that die was cast, the industry kept pulling me back into its orbit. It is nearly always that the employer initiates the contact for a new opportunity.

GoPro is no exception, with lots of analog work in capturing audio and video from the physical world while streaming geo-located image data over Wi-Fi. Meanwhile, the in-house graphics chip is as complex as anything I’ve seen on VR/AR headsets, laptops or smartphones.

Like most other handheld products, size, performance and battery life are the competing interests. The company wisely gives us cameras and encourages us to put them through their paces. It gets packed along for my morning walk out by the bay. Then, when something isn’t responding as it should, I can raise the issue with the development team.

Read Full Article

The 5 Pillars of PCB Design Best Practices

Our newest column shares tips and tricks and lessons learned over 30 years in PCB design.

With today’s complex printed circuit board (PCB) designs challenging us at almost every stage of the design process, along with shortened project schedules and shrinking budgets, achieving success is no easy feat. Smaller component packages, faster signal edge rates or rise times, and increased design for manufacturing (DfM) challenges all make it difficult to achieve success and get product to market on time and under budget. The foundation for achieving success is understanding PCB design (the full design process) and mastering the power of today’s EDA tools.

Even so, design teams can lose valuable time on unproductive tasks. Designers need a collaborative approach to electronic systems design that keeps them connected through all engineering disciplines and gives them best-in-class solutions to handle complexity across the entire PCB design process.

More specifically, we are experiencing heightened complexity in four key areas.

- Product complexity, including advanced packaging technologies, transmission speeds, multi-discipline co-design, component count and density, form-factor, and material technologies.

Pervasive Virtual Reality, Driven by Gamers, Could Bring Exciting Opportunities for Professionals

Is the next generation of designers honing its skills on Minecraft?

If there were a record for the longest wait for a technology to take off (longest gestation period for a new technology), then virtual reality must surely be a top candidate for the honor. As long ago as 1990, the movie Total Recall gave mainstream audiences a dystopian view of the way life could be. The intervening three decades have cemented the image of the headset-wearing gamer in our minds – totally immersed in the experience yet oblivious to all around. And still it has failed to gain a large-scale following. Until now, perhaps.

With equipment sales currently rising at about 14% per annum according to research by IDC, all the big consumer technology brands are planning major new product launches in the coming months. Growth should accelerate to more than 30% in the next five years.

Of course, it’s all about computing performance, power and cost: the computing to deliver lifelike experiences at lifelike speed, within a lightweight, wearable form factor, and at an affordable price. Finally, all three criteria appear to be satisfied and the marketers feel that gamers are now ready to take their passion to the next level.

Read Full Article

Reflections from Discontinuities

Models for predicting the effects of signal-destroying reflections.

by Yuriy Shlepnev

An ideal digital interconnect is a lossless transmission line with characteristic impedance and phase delay flat over the signal bandwidth and termination resistors equal to the characteristic impedance. In such interconnect, bits generated by a transmitter would flow seamlessly into the receiver with no limits on the bit rate. Such a utopian transmission line exists only in our imagination – and in textbooks. The physics of our world prohibits that. One way to describe “what happens to the signal on the way to a receiver” is to use the balance of power that can be written for the passive interconnect as follows:

P_out = P_in – P_absorbed – P_reflected – P_leaked + P_coupled

This is in frequency domain over the bandwidth of the signal as defined in Shlepnev.1 P_out is the power delivered to the receiver and P_in is the power delivered by transmitter to the interconnect. All other terms in the balance of power equation describe the signal distortion. The formula above expresses all we need to know about the interconnects (it should be “cast in granite”). As they say, “a formula is worth a thousand words,” almost literally in this case. To understand it, just imagine the interconnect system as a multiport with the transmitter at port 1, receiver at port 2 and multiple other ports for links coupled to the link connecting port 1 and 2 and terminations to real impedance (not necessarily identical at all ports). In short, something like FIGURE 1 together with the definition of waves and scattering parameters (or S-parameters).

The Harringon’s concept of “loaded scatterers” allows us to turn any interconnect system (even malfunctioning as an antenna) into a multiport and describe it with the waves and scattering parameters, as in Figure 1. Furthermore, the choice of real Zo for all ports makes those waves the “power waves.” Now we can define the powers in the balance of power equation through the multiport waves a and b as follows:

Read Full Article

Selective Soldering: A Need for Innovation and Development

Improving nozzle wettability will permit more challenging joints to be tackled.

by Samuel J. McMaster, Andrew Cobley, John E. Graves and Nigel Monk

Selective soldering utilizes a nozzle to apply solder to components on the underside of printed circuit boards (PCBs). This nozzle can be moved to either perform dips (depositing solder to a single component) or draws (applying solder to several components in a single movement). The selective soldering methodology thereby permits the process to be tailored to specific joints and permits multiple nozzle types to be used if required on the circuit board.

Nozzles can vary by size (internal diameter) and shape (making them suitable for different process types). This is all dictated by board design and process requirements. Selection of the nozzle type depends on the product to be soldered and the desired cycle time. Examples of different nozzle types are shown at pillarhouse.co.uk.

Hand-load selective systems must be programmed with the parameters for multiple solder joints. Many inline systems are designed to be modular, however. This modularity permits multiple solder stations with different conditions/nozzles to achieve low cycle times. FIGURE 1 shows the two distinct types of selective soldering systems offered by Pillarhouse International Ltd.

Selective soldering provides many other benefits compared to wave and hand soldering, such as:

- Minimal thermal shock

- Lower running costs than wave soldering

- Operation under an inert environment to minimize soldering defects, reduce dross production and improve wetting performance (more details below)

- Applicability to low- and high-volume production

- Repeatability in the process and solder joints

- Fewer operators required.

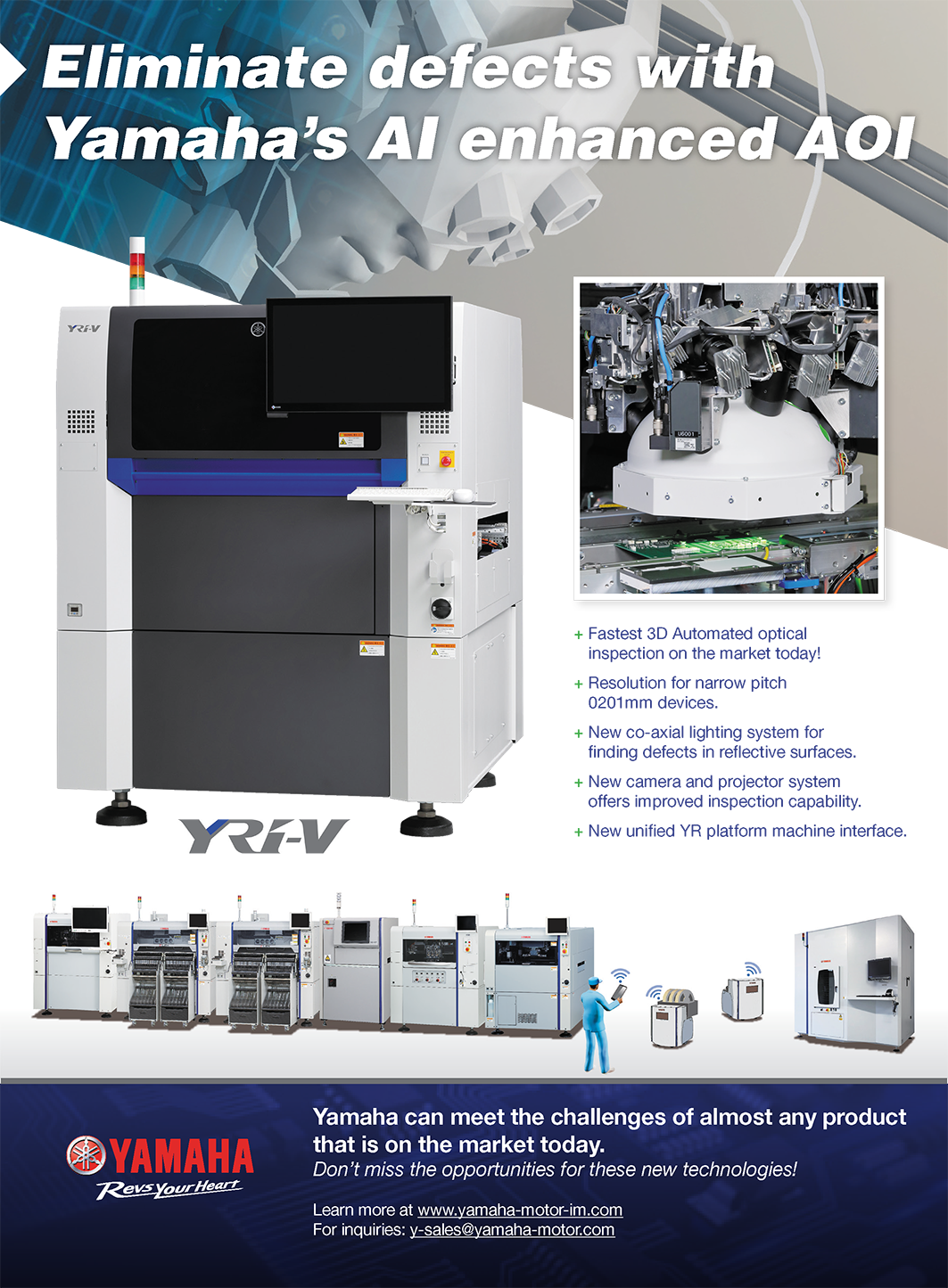

Programming-Free, AI-Powered Visual Quality Inspection (VQI)

New advances permit defect detection in a fraction of the time.

by Sheldon Fernandez

Despite the prevalence of automated optical inspection (AOI) systems for PCBA manufacturing processes, many organizations still rely on manual inspection for the post-SMT stage of production.

However, three overlapping trends – 1) the industry’s well-documented labor shortage that’s poised to worsen; 2) the projected 15% year-over-year growth in PCB manufacturing; 3) the migration of sensitive electronics manufacturing work back to North America – are obliging organizations to examine automated solutions for manual aspects of their workflow.

To this end, the latest advances in artificial intelligence (AI) – the “second wave” of AI characterized by machine learning and deep learning technologies – means that manufacturers can finally reap the rewards of reliable and high-performance automated inspection for the post-SMT and final assembly stages of production.

What AI Means for Assembly

Deep learning is a ubiquitous technology that excels at image identification tasks, and the state-of-the-art has enabled the creation of high-performance models that remain computationally efficient. But, at the risk of sounding flippant, so what?

Read Full Article

VVDN Goes Vertical

India’s largest ODM is looking to add PCB fabrication to complete its end-to-end mix.

by Mike Buetow

VVDN is perhaps best known as a provider of end-to-end engineering and manufacturing of hardware, mechanical and electronics assemblies, and embedded software, among others. Founded in 2007, it now has 11 product engineering centers worldwide, plus seven manufacturing plants across India, where its capabilities include SMT injection molding, tooling, die casting and metal stamping among others.

VVDN builds products for a range of end-markets, including cameras for surveillance and security communications products such as 5G radio units and 4G and 5G antenna; consumer products like wearables and Wi-Fi-based access points; computing products like HPCs and telecom servers, laptops and tablets; and automotive electronics such as automotive vision systems, ADAS, EV chargers, infotainment systems and more.

The company, which says it is India’s largest ODM, in February announced plans to invest $100 million over the next five years in a new 100-acre factory in Tamil Nadu. That plant will add PCB fabrication capability, rounding out the firm’s vertical integration strategy.

We spoke in late March with cofounder and president of engineering Vivek Bansal on the PCB Chat podcast. The following has been edited for clarity and length.

Read Full Article

Alvaro

Gardo

ESD Protection and Packaging/Unpackaging

A DoE reveals the packaging type matters less than the process used.

The need for electrostatic discharge (ESD) protection is drilled into production workers from day one in most electronics manufacturing facilities. Most facilities have multiple layers of protection including floor tiles or conductive coating, smocks, individual grounding devices, ESD mats on workstations, and ionizing blowers throughout the production process. There are also multiple layers of protection from conductive totes to metalized bags for product as it ships out. There is a tendency to believe more protection is always better. Given that the seven wastes include both defects and overprocessing, however, from a Lean manufacturing standpoint there is value in analyzing how much protection is required for shipped products. Considering whether multiple layers of protection create a false sense of security with operators involved in pack/unpack operations also has value.

The team at SigmaTron’s facility in Chihuahua, Mexico, recently studied what types of packaging and processes provide the most value in terms of ESD protection during the pack/unpack process. The primary goal was to understand if packaging or processing deficiencies were creating defect opportunities in either the packing process at the EMS facility or the unpack process at an OEM’s facility, and implement appropriate corrective action. A secondary goal was to utilize the design of experiments (DoE) data to optimize packaging decisions so that products were appropriately protected by the right level of ESD protection.

Read Full Article

PCD&F

Cadence Allegro X AI ECAD

Allegro X Artificial Intelligence (AI) design software automates placement, metal pouring and critical net routing, and is integrated with fast SI/PI analysis. Using generative AI capabilities, streamlines system design process, achieving a 10X or more reduction in PCB design turnaround time. Enables feasibility analysis in early phases of design.

Cadence Design Systems

KiCad 7.0.1 ECAD

KiCad 7.0.1 fixes various bugs, improves print quality when using custom fonts, fixes CADStar importer memory leaks, handle dielectric sub-layers in STEP export, and more.

KiCad

CA

Aegis FactoryLogix MES

FactoryLogix 2023.1 and 2023.2 releases deliver enhancements across the entire platform. PLC Gateway simplifies and enables real-time connection and data transformation into standards-based IIoT between PLC equipment and any software system. Upgraded composable UI designer enables customers to craft a unique interface per operator station using a vast library of ready-to-use applets. Integrates with Arena PLM. Enhanced Limit Rework Attempts capability eliminates costly rework and repair actions by limiting rework events by inspection code and reference location.

Aegis Software

Arch Systems Action Manager

Arch FX Action Manager automates responses to alerts using real-time data and built-in industry knowledge. Combines direct-to-machine connectors, globally scalable data brokers, cloud-based analytics, and action monitoring capabilities for an end-to-end solution that improves speed from project conception to analytics-driven actions.

Arch Systems

In Case You Missed It

Electrochemical Migration

“Effects of Concentration of Adipic Acid on the Electrochemical Migration of Tin for Printed Circuit Board Assembly”

Author: Yi Sing Goh, et al.

Abstract: The continuous advancement in innovative electronic applications leads to closer interconnection spacing and higher electric field density, thus increasing the risk of electrochemical migration (ECM)-related failures. The ECM of tin (Sn) attracts great interest due to the wide use of Sn on the surface of the printed circuit board assembly. In this work, the authors investigated the effects of adipic acid (1ppm – saturated concentration) on the ECM of Sn using the water drop test (WDT) at 5V. In situ observation and ex situ characterization of ECM products were carried out using optical and electrochemical techniques. Results show that the electrochemical migration failure probability is higher at intermediate adipic acid concentrations (10ppm, 100ppm and 1000ppm). The major ECM reactions include anodic corrosion and the formation of dendrites, precipitates and gas bubbles. ECM failure does not occur at higher adipic acid concentrations (±5000ppm), although the anodic corrosion becomes more severe. The complexation of Sn with adipic acid to form Sn adipate complex is suggested as the main factor suppressing ECM failure at higher concentrations (±5000ppm) by retarding ion transport. The electrochemical parameters (Ecorr and Icorr) do not correlate with ECM failure probability. They affect the anodic dissolution stage, but not the subsequent stages in the ECM mechanism. In this study, the ion transport stage plays a more significant role in determining the ECM failure probability. (Journal of Electronic Materials, January 2023; https://link.springer.com/article/10.1007/s11664-022-10155-2)

MBSE

“Adoption of Model-Based Systems Engineering in Traditional DoD Systems”

Authors: Capt. Patrick Assef, USAF, and Lt. Col. Jeremy Geiger, USAF

Abstract: The transition to digital engineering has become a major objective within the US Department of Defense (DoD). One such method is model-based systems engineering (MBSE), or the use of models to facilitate systems engineering. Most new US DoD programs are being built from the ground up using MBSE. The question of whether MBSE should be incorporated into existing systems lingers, however. Little research currently exists on the efforts required to transition existing systems to MBSE. In this article, the authors measure the effort required to transition an existing system of systems (SoS), which primarily relied on document-centric methods, to MBSE.

Read Full Article