November 2023

PCEA

PO BOX 807

AMESBURY, MA 01913

PCEA BOARD OF DIRECTORS

Stephen Chavez, CHAIRMAN

Justin Fleming, SECRETARY

Gary Ferrari, CHAIRMAN EMERITUS

MEMBERS

Michael Buetow

Tomas Chester

Douglas Dixon

Richard Hartley

Scott McCurdy

Anaya Vardya

Susy Webb

Eriko Yamato

pcea.net

PUBLICATION

- PCD&F/Circuits Assembly digital.pcea.net

WEBSITES

- PCD&F pcdandf.com

- Circuits Assembly circuitsassembly.com

NEWSLETTER

- PCB Update pcbupdate.com

PODCASTS

- PCB Chat pcbchat.com

EVENTS

- PCB West pcbwest.com

- PCB East pcbeast.com

EDUCATION

- PCB2Day pcb2day.com

- PCEA Training pceatraining.net

- Printed Circuit University printedcircuituniversity.com

AWARDS PROGRAMS

- Service Excellence Awards circuitsassembly.com

- NPI Awards circuitsassembly.com

pcdandf.com

DATABASE

- Directory of EMS Companies circuitsassembly.com

mike@pcea.net

frances@pcea.net

tyler@pcea.net

jacqueline@pcea.net

Clive Ashmore, Peter Bigelow, Robert Boguski, John D. Borneman, John Burkhert, Jr., Stephen Chavez, Mark Finstad, Geoffrey Hazelett, Nick Koop, Geoffrey Leeds, Alun Morgan, Susan Mucha, Greg Papandrew, Chrys Shea, Jan Vardaman, Gene Weiner

frances@pcea.net

mike@pcea.net

jacqueline@pcea.net

PRINTED CIRCUIT DESIGN & FAB/CIRCUITS ASSEMBLY is distributed without charge to qualified subscribers. To subscribe, visit pcdandf.com or circuitsassembly.com and click on Subscribe.

For changes or cancellations to existing subscriptions: subscriptions@pcea.net

PRINTED CIRCUIT DESIGN & FAB/CIRCUITS ASSEMBLY is published monthly by Printed Circuit Engineering Association, Inc., PO Box 807 Amesbury, MA 01913. ISSN 1939-5442. GST 124513185/ Agreement #1419617.

© 2023, by Printed Circuit Engineering Association, Inc. All rights reserved. Reproduction of material appearing in PRINTED CIRCUIT DESIGN & FAB/CIRCUITS ASSEMBLY is forbidden without written permission.

Why is China Provoking Foxconn?

As anyone who has visited Acapulco knows, it is picturesque, with the serene mountain scape overlooking the half-moon bay.

Pictures, as we also know, can be deceiving.

For the better part of the decade, the once-classic vacation spot has been overrun with drug gangs, and the former wave of tourists has diminished to a trickle. And that was before Hurricane Otis hit last month.

As 2023 draws near its end, we are reminded of how much uncertainty lies ahead. Whether man-made, like the regional conflicts in Europe, the Middle East, Africa and the Pacific Rim; or natural disasters, such as those experienced in Mexico, Turkey and the US, we seem awash in challenges and obstacles.

And then there are the completely self-inflicted wounds.

READ FULL ARTICLE

Icape Group Makes 3 US Acquisitions

FONTENAY-AUX-ROSES, FRANCE – Icape Group has announced the acquisition of three US companies: PCB Solutions, Ustek Inc. and Nujay Technologies.

The three companies have each specialized in PCB distribution in the US for over 20 years. PCB Solutions and Ustek also distribute technical parts, representing 10% and 30%, respectively, of their businesses. In total, the three companies have a portfolio of more than 180 North American customers from a variety of industries, ranging from medical equipment design to the automotive sector. In 2022, these three companies generated a cumulative net revenue of over $5 million and an EBITDA margin of over 10%.

In making the acquisitions, Icape strengthens its foothold in the US by gathering a strong pool of industrial customers, as well as new distribution channels, and the different locations of the new acquisitions (in Ohio, California and Utah) also enable the group to cover the entire US territory, the company said in a release.

READ FULL ARTICLEDoD Awards $17M to Microelectronics Industrial Initiatives

WASHINGTON – The Department of Defense’s Office of Industrial Base Policy has awarded a combined $17.5 million in contracts to support two initiatives that will strengthen the resilience of the defense microelectronics industrial base – including a project to promote production of ultra-high-density interconnects for PCBs.

The DoD, through its Manufacturing Capability Expansion and Investment Prioritization (MCEIP) office, awarded $11.5 million in the Defense Business Accelerator (DBX) and Printed Circuit Board Market Catalyst project, which will harness private capital and commercial market forces to scale defense-relevant technologies and rapidly expand the industrial base.

The PCB Market Catalyst project will deliver a detailed plan for the creation of a new company that will stimulate demand for domestic production of ultra-high-density interconnects for PCBs. The plan will then be presented to the DoD for a decision on whether to fund the creation of the new company. The PCB Market Catalyst will enable the US to surmount an impasse that has left it behind in the global PCB market. DBX leverages commercial market forces to accelerate the transition of emerging defense technologies into sustainable businesses to fill supply chain gaps. Both DBX and PCB Market Catalyst are being executed by the US Partnership for Assured Electronics in partnership with Advanced Technology International, with initial funding from MCEIP of $11.5 million over three years.

READ FULL ARTICLECEA and Siemens Collaborate to Expand Applications of Digital Twin

PLANO, TX – Siemens Digital Industries Software and CEA-List, a technological research institute focused on smart digital systems research, have signed a memorandum of understanding to collaborate on research to further extend and enhance digital twin capabilities with artificial intelligence and explore greater integration of embedded software on both virtual and hybrid platforms.

The research collaboration will bring together the two organizations’ combined industry expertise with the Siemens Xcelerator portfolio and CEA-List’s toolset to help break down the barriers between electronics design, software development and mechanical engineering disciplines using digital twin technologies. This is expected to help customers to significantly reduce the time and cost of verification and validation and to drive significant improvements in product quality and accelerate time to market across the full electronics systems product lifecycle; from architectural exploration to design and development. Alongside this, the research will further explore the use of digital twin technologies for autonomous driving, smart robotics and health domains.

READ FULL ARTICLESnapEDA Rebrands as SnapMagic, Adds AI PCB Design Features

SAN FRANCISCO – SnapEDA, a provider of footprints and models for electronic components, has announced a rebranding as SnapMagic and the release of a new AI-based tool for circuit board design.

The new tool, SnapMagic Copilot, combines artificial intelligence with the firm’s proprietary dataset. The combination, SnapMagic said, streamlines certain repetitive aspects of electronics design.

For instance, the new tool auto-completes circuits and suggests related parts to fill out a design. Users can issue instructions in plain English – for example, requesting “non-inverting amplifier with a gain of 2” – and SnapMagic Copilot will use “solid” circuit theory fundamentals to design the circuits using available parts. It can also propose a manufacturer-endorsed reference design.

For bills-of-materials, the tool will suggest pin compatible replacements at different price points, and can recommend alternatives when inventories are low.

READ FULL ARTICLEKrypton Solutions to Invest $100M in Karnataka Facility

BOMMASANDRA, INDIA – Krypton Solutions is planning to invest $100 million to establish a PCB fabrication facility in the Indian state of Karnataka, the company confirmed to PCD&F/CIRCUITS ASSEMBLY in October.

“We are planning a PCB plant in India in 2024,” Dipak Patel, owner, Krypton Solutions, told PCD&F/CIRCUITS ASSEMBLY.

The decision to invest was announced during a meeting between the company’s representatives and an official delegation led by MB Patil, Karnataka’s Minister of Large & Medium Industries.

Krypton Solutions intends to set up its new plant in Bommasandra, Bengaluru and has already engaged in preliminary discussions with the government.

“During the meeting, the company also explored potential investment opportunities in Mysuru and Chamarajanagar within the state. Furthermore, Krypton expressed interest in forming local partnerships and sought support in identifying suitable entry and growth partners in the Indian market,” Patil said in a statement.

Krypton also has EMS facilities in Plano, TX; San Jose; and India.

IPC Updates Board Qualification Spec

BANNOCKBURN, IL – IPC has released IPC-6012F, Qualification and Performance Specification for Rigid Printed Boards, the base standard for bare circuit boards.

IPC-6012 provides requirements for the qualification and performance of rigid printed boards based on constructions and /or technologies such as; single-sided, double-sided printed boards with and without plated-through holes (PTH), multilayer printed boards with PTHs with or without buried/blind vias/microvias, active/passive embedded circuitry printed boards with distributive capacitive planes and/or capacitive or resistive components and metal core printed boards with or without an external metal heat frame, which may be active or non-active.

Among the many additions to IPC-6012F, are expanded requirements in the following areas: printed board cavities, copper wrap plating, “Intermediate” target lands, solderability testing, dewetting, microsection evaluation, internal plated layers, dielectric spacing and reliability issues with microvia structures.

READ FULL ARTICLECalumet Electronics to Build Substrate Manufacturing Facility in MI

CALUMET, MI – Calumet Electronics is on track to building a substrate factory in the US with a 60,000 sq. ft. facility on its campus in Michigan’s Upper Peninsula.

The project is expected to generate a total capital investment of up to $51 million. That amount includes a $7.5 million incentive from the Michigan Economic Development Corporation and a 15-year tax break of up to $758,877 per year.

Over the next three years, while the company scales its substrate production with training and technology, 270 of its current 350 employees will be retained to maintain the standard current production needs. Forty existing employees will receive initial upskilling critical to manufacturing advanced package substrates and complex PCB technologies in support of the semiconductor ecosystem and defense complex.

READ FULL ARTICLEAmphenol to Acquire PCTEL for $140M

WALLINGFORD, CT – Amphenol has announced an agreement to purchase wireless equipment maker PCTEL for $139.7 million. The transaction is expected to be finalized in the fourth quarter or in early 2024, subject to customary closing conditions and approval by PCTEL stockholders.

Amphenol said the acquisition of PCTEL, which specializes in purpose-built Industrial IoT devices, antenna systems, and test and measurement products, will enable the company to further expand its portfolio and strengthen its position in the market.

“Our team has done an excellent job of growing the business, establishing a leadership position in both antenna and test & measurement (T&M) innovation, and meeting our customers’ strong global demand for high reliability applications,” said PCTEL CEO David Neumann. “Amphenol is a leading global provider of interconnect, sensor, and antenna solutions. Their sustained financial strength and unique entrepreneurial culture will create a valuable home for our employees around the world. We look forward to the accelerated growth opportunities enabled by the combination of our two companies.”

Following the closure, PCTEL will no longer be listed on any public market.

Foxconn Subjected to Tax Inspections by Chinese Authorities

TAIPEI – Foxconn’s Chinese facilities were recently subjected to searches by Chinese tax authorities, and speculation is rampant that the investigation was spurred by Foxconn’s largest shareholder’s bid for the Taiwanese presidency.

The company had its offices in Guangdong and Jiangsu provinces searched by tax officials, according to a report in China’s Global Times newspaper.

The Ministry of Natural Resources also inspected Foxconn offices in Henan and Hubei provinces, where the company has major factories. Foxconn employs hundreds of thousands of workers across China.

Observers suggested that the tax investigation is a smokescreen to put pressure on Terry Gou, Foxconn’s founder and principal owner. Gou is running for president of the island nation, and his independent bid could split the vote for the Kuomintang party, which is said to be preferred by the Chinese leadership because of its mainland leanings.

New Roadmap Identifies Critical Semiconductor Research Priorities

WASHINGTON – The Semiconductor Research Corporation has unveiled the Microelectronics and Advanced Packaging (MAPT) Roadmap, which defines critical chip research priorities and technology challenges that must be addressed to support the “seismic shifts” outlined in the Decadal Plan for Semiconductors released by SRC and SIA in January 2021.

The Decadal Plan identified five seismic shifts in the industry related to smart sensing, memory and storage, communication, security, and energy efficient computing. The MAPT Roadmap continues the spirit of the Decadal Plan and discusses how to achieve its system-level goals, outlining the implementation plan for the semiconductor industry.

The fundamental research that will transform these obstacles is focused on advanced packaging, 3-D integration, electronic design automation, nanoscale manufacturing, new materials, and energy-efficient computing. The MAPT Roadmap is framed around fundamental and practical limits of information and communications technology sustainability: energy sustainability, environmental sustainability, and workforce sustainability.

READ FULL ARTICLEIndium Acquires Low-Heat Solder Developer

CLINTON, NY – After partnering with the company last year to develop a supercooled liquid metal solder paste, Indium Corp. in October announced the acquisition of Safi-Tech. Financial terms were not disclosed.

Last year, Indium collaborated with Safi-Tech to launch a supercooled BiSn solder paste using the latter’s solder platform. That platform permits molten metal to remain liquid far below its freezing point by encapsulating it in a smooth shell – known as supercooling. The shell of these microcapsules can be removed using a traditional flux and reflow process, or by mechanically crushing a powder of supercooled liquid metal microcapsules. Using this platform, industry-standard alloys such as SAC 305 can be soldered at below typical low-temperature solder (LTS) specifications, while other alloys can be soldered at temperatures as low as ambient.

“Safi-Tech’s supercooling platform is an exciting addition to our award-winning product portfolio, allowing us to deliver next-generation soldering materials,” said Ross Berntson, president and COO, Indium. “This innovation has far-reaching potential and embedding Safi-Tech into Indium gives it the opportunity to succeed widely and quickly.”

READ FULL ARTICLEAIM Solder Purchases William Rowland’s Solder Business

LUTON, UK – AIM Solder UK has announced the acquisition of William Rowland Ltd.’s solder products business, encompassing solders and alloys. Financial terms were not disclosed.

This acquisition will expand AIM Solder’s capabilities and enhance customer offerings in the metal industry, the company said in a release.

“This strategic move allows AIM Solder to further enhance its position in the solder industry by leveraging William Rowland’s legacy and expertise in this specific sector,” said Ricky Black, president, AIM Solder. “We are excited to welcome William Rowland’s solder customers into the AIM Solder family, and we are committed to preserving the values that have made them a trusted name in this field.”

ECIA Publishes Update on Anti-Counterfeiting Standard

ATLANTA – ECIA’s Global Industry Practices Committee (GIPC) has published an ECIA Update document based on the five-year review process conducted by SAE’s AS6496 Standard Committee. There have been changes to the standard, which is out for the final vote. The updated version, AS6496A, is expected to be available by the end of the year.

The Society of Aerospace Engineers’ (SAE’s) AS6496 is an anti-counterfeiting measure outlining requirements for mitigating counterfeit products in the authorized supply chain by distributors performing authorized distribution. SAE adopted this standard on Aug. 20, 2014, with the official title of “Fraudulent/Counterfeit Electronic Parts: Avoidance, Detection, Mitigation and Disposition – Authorized/Franchised Distribution.”

The standard is used by authorized distributors to reduce the risk of counterfeit components entering the aerospace supply chain, but it is a reliable anti-counterfeiting model for any customer.

READ FULL ARTICLEZollner Opens Chinese Plant Expansion

TAICANG, CHINA – Zollner Elektronik has expanded its plant here to meet the growing demands of the international market.

With around 17,000 sq. m. of building space, the new plant building includes a cleanroom, two stories of production space for PCB and device assembly, a large warehouse area, a large cafeteria, and social areas as well as office space. The additional production space takes up 15,000 sq. m. and was conceived specifically to increase the company’s production efficiency and capacity and create more jobs, Zollner said in a release.

The company said the expansion also underscores its long-term vision and commitment to the Taicang region and is a significant milestone in the history of the company.

“We are confident that Taicang offers excellent opportunities and conditions, particularly for the production of complex products, which will unlock further possibilities and potential for our company,” said board member Markus Aschenbrenner.

Cicor to Acquire STS Defence

BRONSCHHOFEN, SWITZERLAND – Cicor will acquire STS Defence, a UK-based provider of sustainment, support and modernization solutions for the aerospace and defense markets.

STS Defence has earned an outstanding decades-long reputation for solving complex technical challenges by delivering innovative solutions and programs, and employs around 150 people, Cicor said in a release announcing the acquisition.

The company said the combination of the strengths of Axis Electronics, which was acquired in 2021, and STS Defence, will ideally position Cicor to implement the most demanding customer programs with a focus on the UK market. STS Defence generated sales of GBP27.5 million ($33.5 million) in the fiscal year ended on June 30.

Cicor said it will continue to provide engineering support and manufacturing services from the existing STS Defence site under the current management team, and closing of the transaction is expected within 2023 and is subject to regulatory approvals and other customary closing conditions.

PCD&F

Eltek announced a $2.9 million purchase order from an existing customer.

Foxconn will reportedly set up a PCB fabrication plant in India.

Jingwang Electronic broke ground on a high-rise multilayer PCB production facility in Xinfeng County Shenzhen Industrial Park.

Korea Circuit won a large order from STMicroelectronics to supply it with FC-BGA substrates.

PS Electronics has ramped up its investments in LCP PCB manufacturing technologies and equipment.

Read Full ArticleCA

ANYbotics is collaborating with Zollner Elektronik for serial production of its ANYmal robot.

Asus is setting up a factory in Chennai, India, through its contract manufacturer Flex.

CDIL has commenced production of silicon carbide devices through surface mount technology at its manufacturing facility in Mohali.

CoolCAD announced a strategic partnership with rep agency NWN.

Creation Technologies will supply circuit card assemblies, cables and connectors to L3Harris Technologies for a multitude of mission critical defense programs.

Read Full Article

PCD&F

APCT appointed Peter Austin president and CEO.

HDP User Group named Karl Sauter project facilitator.

MacDermid Enthone Industrial Solutions named Hui Hui Kiw vice president Asia.

Mark Hughes, Jesse Robinson and Kaushlesh Chandel have founded Boondock Technologies.

Nano Dimension appointed Gen. (Ret.) Michael Garrett to its board of directors.

Schweitzer Engineering Laboratories promoted Greg Zweigle to CTO.

TTM Technologies CFO Dan Boehle was honored at the 2023 Los Angeles Business Journal CFO of the Year Awards ceremony.

CA

AIM Solder appointed Henry Colina technical sales engineer and Josh Zhou regional sales manager.

Alliance Memory appointed Kim Newman global account manager for Jabil.

Bowman XRF named Landon Robertson technical sales engineer for the US Eastern region.

Elcina elected Dixon Technologies’ Atul Lall president for 2023-24.

Escatec promoted Lambert Schutters to CPO.

Read Full Article

PCB Design Training Classes for 2024 Announced

PEACHTREE CITY, GA – PCEA Training is offering three upcoming training classes in 2024 over a span of five days (one class per week) for printed circuit engineers, layout professionals, and other individuals currently serving in the design engineering industry or seeking to get into it. The one-day-per-week class schedule varies from previous iterations in which classes were held five straight days.

Upcoming class dates include:

- Class 1: Feb. 5, 12, 20, 26, March 4

- Class 2: April 5, 12, 19, 26, May 3

- Class 3: June 14, 17, 21, 24, 28

PCB West 2024 Opens Booth Space to All Vendors

PEACHTREE CITY, GA – The exhibition floor for PCB West 2024 is now open to any interested company, the Printed Circuit Engineering Association (PCEA) announced in late October.

The show floor is expected to sell out, show organizers added, as booth space is now open to companies that did not exhibit last year.

Booth sales opened in mid-October to returning exhibitors, and the show floor is currently more than 50% sold out.

READ FULL ARTICLENational. PCEA will hold a series of free webinars for members over the coming months. Topics include AI in electronics, component research and parts introduction, PCB material properties and how they affect design and processability, and additive manufacturing. Check the PCEA website calendar for updates.

Ontario (Canada). The chapter is planning an event in December. The likely speaker is Ata Syed, who is continuing a series on flex circuits.

Portland (OR). The chapter held a planning session in October as it prepares for its 2024 calendar.

San Diego. The chapter is looking for a meeting location. It is also on the lookout for guest speakers.

Silicon Valley. The chapter’s next meeting is on Nov. 16. Cadence Design Systems will be hosting and sponsoring lunch. Michael Catrambone, product engineering architect for Cadence Allegro PCB products, is the speaker.

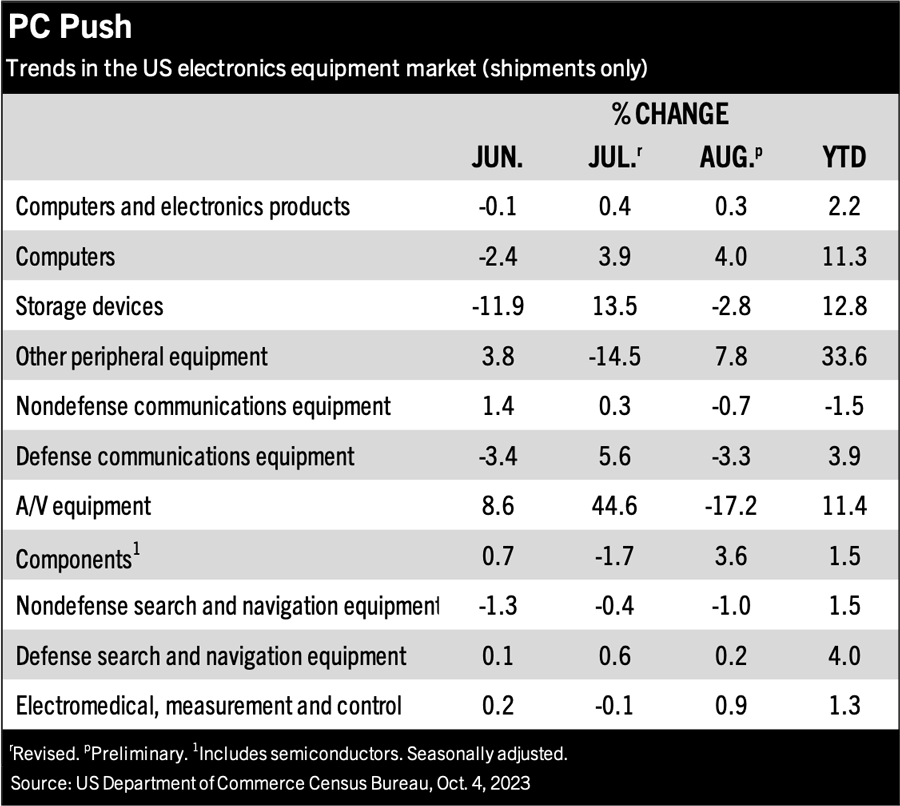

PCB Design Software Revenue Increases 6% in Q2

MILPITAS, CA – Printed circuit board and multichip module design software revenue increased 6.3% in the second quarter to total $369 million, according to the ESD Alliance in October. The four-quarter moving average for PCB and MCM, which compares the most recent four quarters to the prior four, rose 11.7%. (more)

Hot Takes

Orders for electronic products fell 17% year-over-year to $17.2 billion in September, attributable to lower demand for memory chips, foundry services and printed circuit boards as customers were in the process of digesting excessive inventory. (Taiwan Ministry of Economic Affairs)

Taiwan’s PCB output has resumed its growth path after declining in the first half of the year, and is estimated to increase 8.1% annually. (Taiwan Institute of Technology and Research) (more)

Auditing the Auditors

They may be a hassle, but audits can provide valuable insights and ideas for your company.

DURING THE FOURTH quarter of this year, it seems that everyone and their brother have scheduled audits at my company. Some are for certifications such as ISO 9001 and AS9100. Others are customer-driven, as the cloud of Covid has at least partially lifted and after a three-year hiatus customers are able to travel to meet their suppliers. I have always hated audits; however, I also have learned that they can be a powerful tool when incorporated into the business planning process.

First, a disclaimer: I truly hate audits, for three basic reasons.

First, those conducting the audit – especially certification audits – have no clue what you make, the manufacturing challenges faced in producing the product, or industry-specific acceptability standards related to the product that you must meet. These auditors just follow a flat checklist and try to jam the proverbial square peg (your facility) into a round hole (their certification program).

Read Full Article

PCB Design for Virtual and Augmented Reality Headsets

“Non-standard” head shapes mean flex circuits are a given.

WE’VE COME A long way in the AR/VR space. It seems like we’re going to have this stuff whether we want it at the moment or not. It’s kind of like the Northwest Passage through the ice cap. It’s new. We’re not sure what the result looks like, but we’re charging ahead with a virtual and/or augmented future.

Set the wayback machine to 1939, when both my father and the View-Master stereoscope entered the room. This wasn’t long after Kodachrome was invented, so it was cutting-edge at the time. We put circular cards into the slot and could browse seven different views that somehow tricked the eye into seeing depth from isolating each eye on two similar slides (Figure 1).

Back in “real” reality, this technology still has a lot of room to grow. It was about a decade ago when virtual reality started to bubble up into the lexicon at Google. We knew that a new industry was coming into existence and wanted to at least provide a gateway to the content. A group adjacent to the Chrome team developed a product called “Cardboard” that reminded me of the View-Master.

Read Full Article

PCB Design Reuse

Reusing proven circuits and layouts can enhance innovation. Here’s how.

In the ever-evolving field of engineering, the ability to innovate quickly and efficiently is paramount. Design reuse, a practice that involves repurposing and incorporating existing design elements into new projects, has emerged as a powerful strategy to achieve these goals. Boosting efficiency and innovation in the world of engineering, design reuse is a powerful strategy to implement that has the potential to be a game changer.

By reusing known, good, tested, validated, approved circuits and layouts, engineers can save design cycle time, reduce costs, and foster innovation. Plus, IP can be shared throughout enterprise and across designs. Design reuse is not restricted to one discipline as it can be implemented in all the engineering disciplines/domains. The key is to take advantage of the opportunity when it presents itself by not reinventing the wheel every time on a new project/design. This month’s column delves into the concept of design reuse, its benefits, challenges, and how it’s shaping the future of engineering.

Read Full Article

Preparing for 6G

While the 5G era continues to take hold, materials science must advance for us to move to the next stage.

It’s part of the human condition to never be satisfied. We are always looking forward to what comes next, and this tendency is starkly evident in our attitudes toward technology. As our daily lives have become substantially enabled, empowered, and – many would probably agree – enhanced by the technology in our pockets, in our cars, and in our homes and offices, we have become increasingly demanding of more and better. More features and functions, more sophistication, faster responses, less waiting.

Our attitudes toward mobile services illustrate the point. No sooner had 5G networks started rolling out than the focus shifted to 6G and the exciting new opportunities it could bring. But is this a harsh truth about our nature, or simply the reality of a massive scientific and engineering challenge? The mobile industry has established a rhythm that introduces a new generation about once every 10 years: 3G arrived around 2000, 4G-LTE in 2010, and 5G rollouts based on Release 15 of the 3GPP specification began around 2020. 5G evolution has continued, with non-standalone deployments giving way to standalone 5G core and further enhancements in 3GPP Release 16 and 17 to support industrial IoT (IIoT) applications. Release 18 now paves the way for 5G Advanced, which will offer energy savings and greater spectral efficiency, leverage AI to improve network performance, and, of course, enable additional new services and enhanced capabilities.

To ensure 6G – taking performance, reliability, efficiency, and service advancement even further – can be ready for deployment by 2030, work needs to begin now to determine performance targets and start drafting specifications. Where 5G has brought advanced services such as cloud gaming, augmented/virtual reality (AR/VR), and 4K video to our mobiles, 6G will raise the peak data rate from 5G’s 20Gbps to 1Tbps and maximum bandwidth from 1GHz to 100GHz. Latency is expected to reduce from 1ms in 5G to just 100µs, while mobility will double from 500km/h to 1000km/h. Connection density is also expected to rise significantly, to 10 million devices per square kilometer from 1 million today. We can expect these improvements to be manifested in more immersive extended reality (XR) experiences and new capabilities in wireless positioning and remote sensing.

Read Full Article

Assessing Data Independence and Normality for SPC Charts

PCB chemical manufacturing processes can violate data independence and normality.

by Patrick Valentine, Ph.D.

The most critical assumption made concerning statistical process control (SPC) charts is that of data independence from one observation to the next (free from autocorrelation).1,2 The second critical assumption is that the individual observations are approximately normally distributed.1,2 The tabled constants used to calculate the SPC chart limits are constructed under the assumption of independence and normality.

Many printed circuit board chemical manufacturing processes can violate the assumption of data independence. This is because inertial elements drive reduction-oxidation (redox) chemical processes. When the interval between samples becomes small relative to the inertial elements, the sequential observations of the process will be correlated over time.

Statistical process control charts do not work well if the quality attributes charted exhibit even low levels of correlation over time. Correlated data produce too many false alarms – correlated data underestimate the upper and lower control limits.

Read Full ArticleBlock "2311-enh-ventech-ad" not found

See us at PCB Carolina

Booth #63

See us at Productronica

B3.242

Basics of High-Frequency PCB Materials

An overview of the physical and electrical characteristics of rigid and flex laminates.

by Sagi Balter, Ph.D. and Vitaly Bensman

Electronic devices functioning at high frequencies are currently evolving at a dizzying pace, particularly within the field of wireless communication. When developing new products, therefore, emphasis is placed on utilization of materials suitable for high-frequency work, above 1GHz.

When selecting materials intended for high-frequency printed circuit boards, several characteristics are of importance:

- Dielectric constant (Dk) – dielectric coefficient of the resin. This parameter must be low and stable within a wide range of high frequencies. High Dk values may decelerate signal transfer speed.

- Dissipation factor (Df) – the parameter responsible for the signal’s quality. The Df value should be low. The lower this value, the more stable the signal, and losses will be reduced.

- Moisture absorption – another imperative parameter when selecting materials intended for high frequencies. This is important because the Dk of water is Dk;water = 80.4, a value so high, in fact, the absorption of very small amounts of moisture will instigate a significant increase in the overall Dk of the material.

5G Open Radio Unit White Box

An overview of the design and development process.

by Muhammad Irfan

5G radio networks provide increased bandwidth at the expense of reduced range. To compensate for the reduced range and to increase coverage, availability of cost-effective radio units is critical. In collaboration with Intel, Analog Devices, Comcores and Radisys, Whizz Systems has developed a 5G Open Radio Unit (ORU) white box solution to meet this market need. A broader overview of the 5G architecture can be found in Comcores1 and Radisys.2

Here we provide an overview of the design and development process for the various hardware components that make up the 5G ORU white box. Whizz Systems is responsible for the electrical, thermal, mechanical engineering and manufacturing aspects, as well as system validation and bring up of the turnkey white box ORU solution. This includes design of the individual PCBAs and industrial design of the enclosure.

The hardware design leverages Intel’s Arria 10 reference design as a starting point, with power and clocking schemes revamped to meet the updated power and clocking requirements for the ORU platform. An additional JESD interface as a communication pathway is added between the Arria 10 FPGA and Analog Devices-based chip ADRV902X. A board-to-board (BTB) header is added to mate with either the ADI-designed radio frequency front-end (RFFE) card or the Whizz-designed ORU adapter card.

Read Full Article

In-House Fixture Fabrication

Leveraging additive manufacturing technology to mistake-proof production.

One thing OEMs universally agree on is that none of them likes non-recurring engineering (NRE) charges. Implemented as part of new product introduction (NPI), however, custom tooling, fixtures and jigs can eliminate defect opportunities by minimizing process variation that could otherwise occur when those issues can’t be resolved through product design changes. They are also a good tool when a production team identifies the need for a poka-yoke, or mistake-proofing solution, later in a product’s lifecycle.

The concept of poka-yoke was developed by Shigeo Shingo as part of the Toyota Production System (TPS). When applied, the resulting process improvement eliminates a specific defect. Its focus on simplicity is its strength, in that simple fixes are often the best solution for small variances in the manufacturing process. Simple fixes are also easy to rapidly implement and encourage production operator involvement in the pursuit of product perfection. That said, when fixtures are procured through third parties, the cost may exceed the benefit.

The Lean Six Sigma team at SigmaTron International’s facility in Tijuana, Mexico, decided to investigate ways to reduce tooling-related NRE costs by developing in-house 3-D printing and computer numerically controlled (CNC) machining capability. In 2022, they initiated a DMAIC (define, measure, analyze, improve and control) effort to determine necessary equipment and the likely return on investment if the capability was added.

Read Full Article

PCD&F

ALTAIR HYPERWORKS 2023 CAE

HyperWorks 2023 introduces platform-wide enhancements, including a new user experience, faster speeds, an open and programmable architecture, and AI-powered workAows. Allows developers and users to integrate solutions seamlessly, maximizing the platform’s technological potential. All solver solutions – Altair OptiStruct, Altair SimSolid, Altair Feko and others – have also added signiJcant new capabilities. Altair Simulation Cloud Suite allows simulation data management, and Altair HyperMesh CFD features a particular focus on external aerodynamics.

Altair

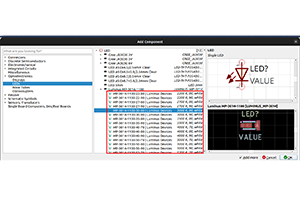

LIBREPCB DESIGN SOFTWARE VER. 1.0

LIBREPCB DESIGN SOFTWARE VER. 1.0

LibrePCB Ver. 1.0 includes new features such as a 3-D viewer and export format for working with designs in a mechanical CAD tool, support for manufacturer part number (MFN) management, and simpliJed exporting of production data. Also includes new board editor features such as thermal relief pads in planes, blind and buried vias, keepout zones, custom footprint pad shapes, and more.

LibrePCB

CA

BOWMAN K SERIES BENCHTOP XRF

K Series benchtop XRF features an expansive measurement area, selectable spot sizes, and high levels of both precision and speed. Has a 12′′x 12′′ measurable area for parts up to 9′′ tall and selectable spot sizes accommodate a wide range of features; focal distances from 0.25′′ to 3.5′′. Has cantilever door design for easy access, and servo motor-driven programmable stage streamlines sample positioning. Also includes table-view functionality to image the entire measurable area and allow the operator to navigate to any location with a single click.

Bowman

BTU AURORA 200N REFLOW OVEN

Aurora 200N convection reAow oven has closed-loop convection control, and 200′′ of heat to support faster line speeds up to 25% faster than those supported by Aurora 150N. Includes modern conveyor options, Aexible heating and cooling conJgurations, an updated user interface, integrated Aqua Scrub Aux management technology, Smart Power energy savings software, and advanced process control technologies. Unit can be shipped in two pieces.

BTU International

In Case You Missed It

Soldering

“Modeling the Effects of Thermal Pad Voiding on Quad Flatpack No-Lead (QFN) Components”

Authors: Ross Wilcoxon, et. al.

Abstract: Finite element modeling was used to evaluate the effects of thermal pad solder voiding on the thermal resistance of quad flatpack no-lead components. This included two different approaches for modeling solder voids: many small, distributed voids, the effects of which were averaged across the entire solder contact area, or a single discrete void. Two approaches were used for defining the thermal path established in the solder. Effects of other design parameters – thermal boundary conditions, the presence of thermal vias under the package, and the size of the die power dissipation area – were also addressed. Modeling showed that thermal vias and external boundary conditions had the most significant impact on the package thermal resistance. Solder pad voids and concentrated die-level heat dissipation, for the range used in this study, had noticeable but less significant impacts on thermal resistance. The study also compared different approaches for simulating solder voiding and identified ranges in which modeling simulations are most appropriate. (Journal of Surface Mount Technology, July 2023, https://doi.org/10.37665/smt.v36i2.37)

Read full article