June 2023

PCEA

PO BOX 807

AMESBURY, MA 01913

PCEA BOARD OF DIRECTORS

Stephen Chavez, CHAIRMAN

Justin Fleming, SECRETARY

Gary Ferrari, CHAIRMAN EMERITUS

MEMBERS

Michael Buetow

Tomas Chester

Michael Creeden

Douglas Dixon

Richard Hartley

Scott McCurdy

Anaya Vardya

Susy Webb

Eriko Yamato

pcea.net

PUBLICATION

- PCD&F/Circuits Assembly digital.pcea.net

WEBSITES

- PCD&F pcdandf.com

- Circuits Assembly circuitsassembly.com

NEWSLETTER

- PCB Update pcbupdate.com

PODCASTS

- PCB Chat pcbchat.com

EVENTS

- PCB West pcbwest.com

- PCB East pcbeast.com

EDUCATION

- PCB2Day pcb2day.com

- Printed Circuit University printedcircuituniversity.com

AWARDS PROGRAMS

- Service Excellence Awards circuitsassembly.com

- NPI Awards circuitsassembly.com

pcdandf.com

DATABASE

- Directory of EMS Companies circuitsassembly.com

mike@pcea.net

frances@pcea.net

brooke@pcea.net

tyler@pcea.net

jacqueline@pcea.net

Clive Ashmore, Peter Bigelow, Robert Boguski, John D. Borneman, John Burkhert, Jr., Stephen Chavez, Mark Finstad, Geoffrey Hazelett, Nick Koop, Alun Morgan, Susan Mucha, Greg Papandrew, Chrys Shea, Jan Vardaman, Gene Weiner

frances@pcea.net

brooke@pcea.net

frances@pcea.net

mike@pcea.net

jacqueline@pcea.net

PRINTED CIRCUIT DESIGN & FAB/CIRCUITS ASSEMBLY is distributed without charge to qualified subscribers. To subscribe, visit pcdandf.com or circuitsassembly.com and click on Subscribe.

For changes or cancellations to existing subscriptions: subscriptions@pcea.net

PRINTED CIRCUIT DESIGN & FAB/CIRCUITS ASSEMBLY is published monthly by Printed Circuit Engineering Association, Inc., PO Box 807 Amesbury, MA 01913. ISSN 1939-5442. GST 124513185/ Agreement #1419617.

© 2023, by Printed Circuit Engineering Association, Inc. All rights reserved. Reproduction of material appearing in PRINTED CIRCUIT DESIGN & FAB/CIRCUITS ASSEMBLY is forbidden without written permission.

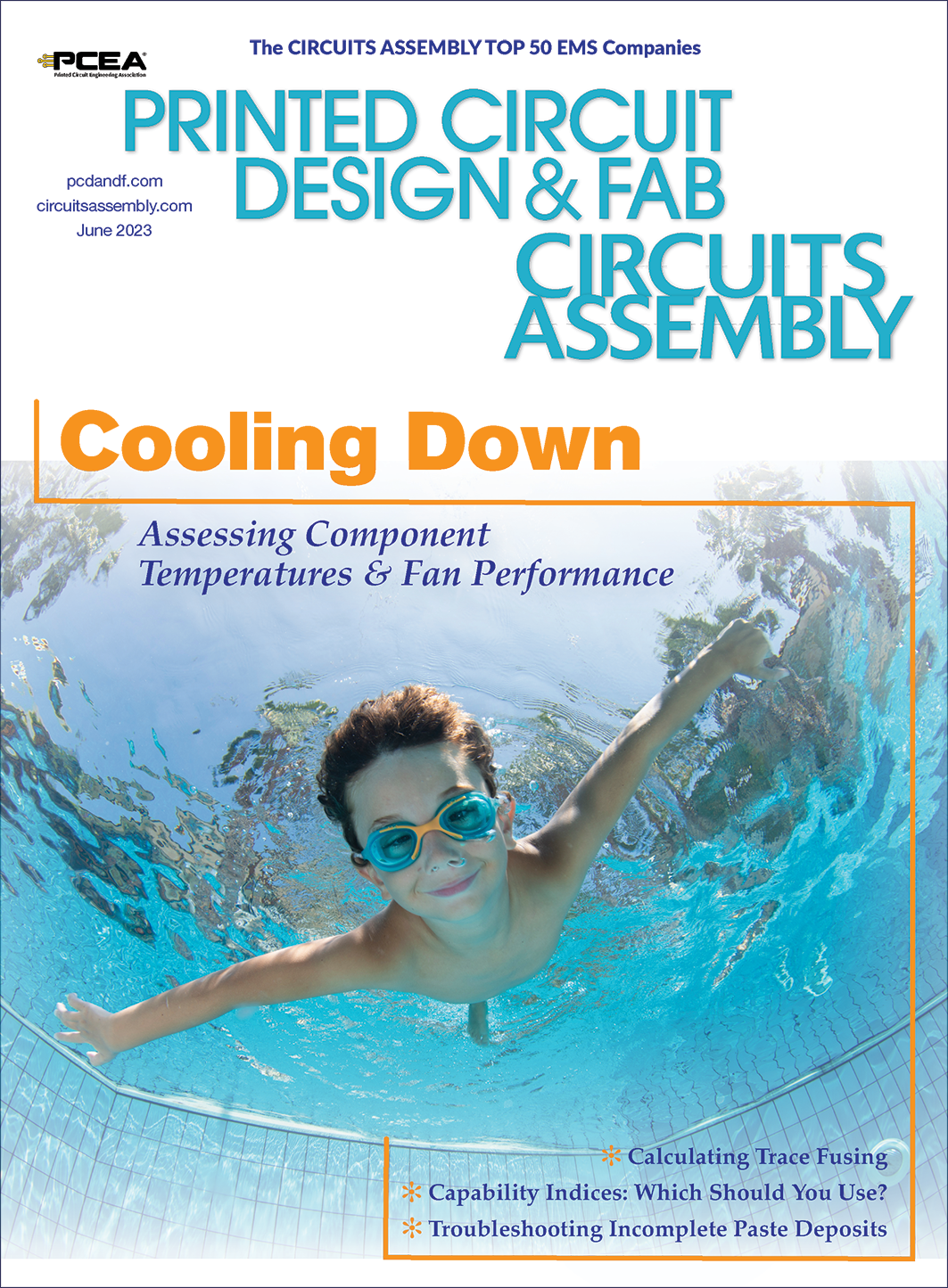

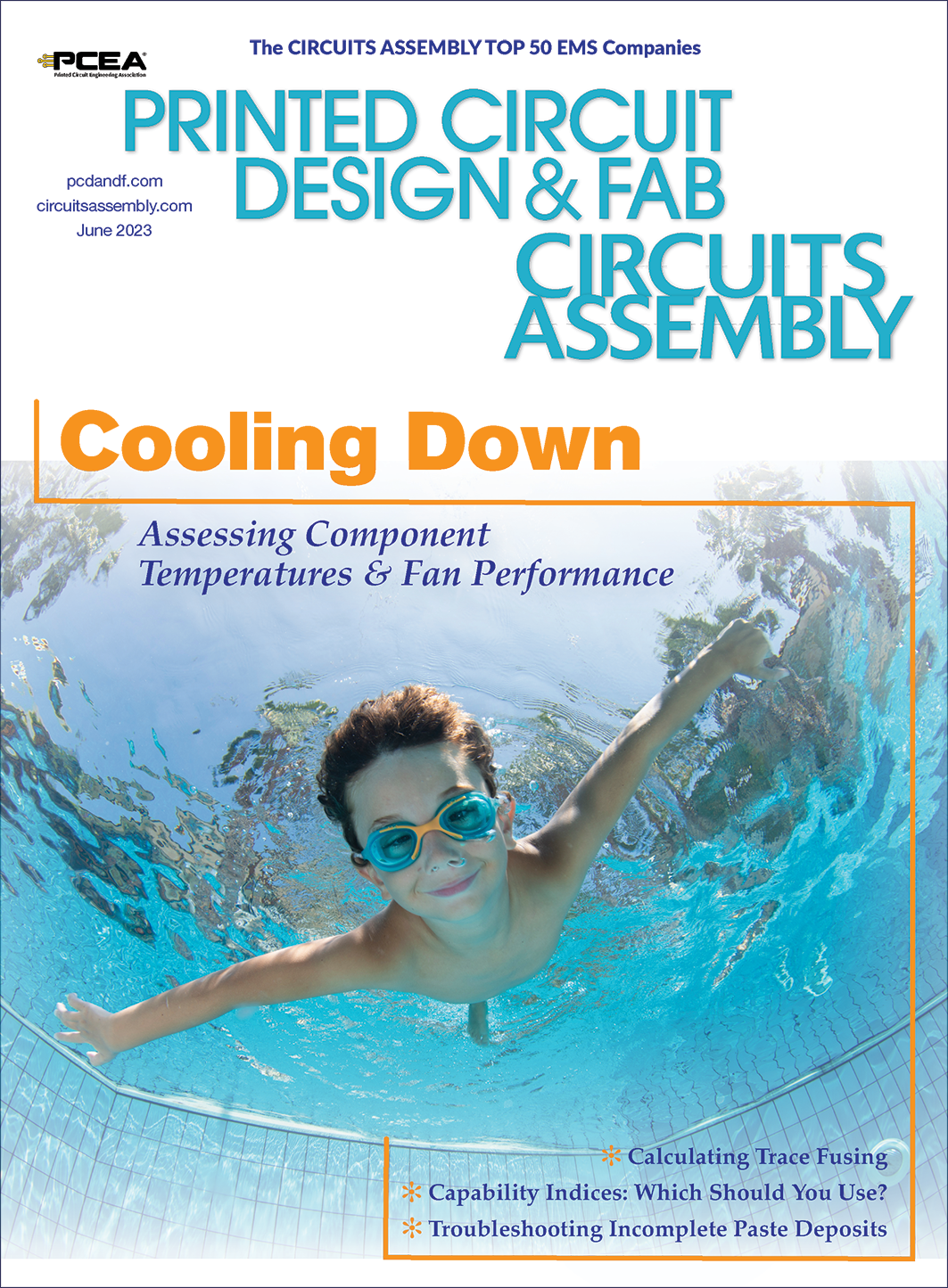

As the Temperature Warms, is the Competition Heating Up Too?

WHEN IT COMES to the monthly editorial content in PCD&F/CIRCUITS ASSEMBLY, we typically don’t do “themes.”

So it’s a matter of randomness and luck that we have not one, not two, but three pieces this month related to electronics thermal management and cooling. Fitting, too, being the month of June is, for the Western Hemisphere at least, on average the warmest of the year to date.

But June is also the month of the most significant trade show in the bare board fabrication industry: The JPCA Show in Tokyo. Regrettably, few Westerners will attend. It’s too bad.

We are seeing significant interest at all levels – technical, management, and even political – at beefing up domestic printed circuit board capabilities. In particular, the West is attempting to make up for decades of failed progress with new investments in IC substrate production.

READ FULL ARTICLE

US Congress Introduces Legislation to Support America’s PCB Industry

WASHINGTON, DC – New bipartisan legislation introduced by US Representatives Blake Moore (R-UT) and Anna Eshoo (D-CA) encourages investment in a trusted, reliable domestic source of PCBs and substrates, and is generating plaudits from an industry association dedicated to building the domestic printed circuit board industry.

The Protecting Circuit Boards and Substrates Act of 2023 “finishes the job the Chips Act began by incentivizing investment in the domestic printed circuit board (PCB) industry,” said the Printed Circuit Board Association of America in a press release. The Chips Act passed by Congress last year allocates tens of billions of dollars in direct funding and tax incentives to promote US technological superiority in semiconductor manufacturing.

READ FULL ARTICLEASKPCB Building New Thai Facility

YIYANG, CHINA – Chinese PCB fabricator ASKPCB is building a factory in Thailand that is expected to have a production capacity of 120,000 sq. m. and be capable of providing volume production of 28-layer PCBs in all fields, including data centers and next-generation switches.

The factory is being built in Thailand’s Rojana Ayutthaya Industrial Park, which is near Wus Group’s Thai factory and near the city center of Bangkok. With a land area of around 26.67 hectares, the Thailand factory is expected to commence trial production by the second quarter of 2024.

In an online investor briefing, the company said the primary goal of the Thailand factory is to address supply-chain security concerns of core customers, providing them with matched services across various domains, including servers, cars, communications, and consumer products.

READ FULL ARTICLETPCA: Taiwan’s PCB Industry Creating New Cluster in Thailand

TAOYUAN CITY, TAIWAN – The Taiwanese PCB industry is increasingly investing in Southeast Asian countries – particularly Thailand – as customers look to secure their manufacturing bases against global uncertainties and move out of mainland China, according to the Taiwan Printed Circuit Association.

Currently, Taiwanese PCB manufacturers have more than 60% of their capacities in Mainland China and 37% in Taiwan, and for many years, Taiwanese companies have not valued the Southeast Asian countries because of their planning and management in Taiwan and mainland China. Since last year, however, international political instability and end-customers’ concern about supply-chain disruption have driven a worldwide trend to relocate the supply chain.

READ FULL ARTICLEAT&S Building New Research Center in Austria

LEOBEN, AUSTRIA – AT&S has received a €250 million loan ($271 million) from European Investment Bank to fund research and development activities and help finance the construction of a new research center at its headquarters here.

The new center in Leoben will help the European Union to achieve digital autonomy, a priority under the European Chips Act, and the goal is to create a chip ecosystem to ensure Europe’s security of supply in microchips and to strengthen its digital technology production capabilities, EIB said in a release.

READ FULL ARTICLEHDP Announces Launch of 3 New Projects

ROUND ROCK, TX – Following the successful completion of its spring member meeting, held in Santa Rosa, CA, in February, the High Density Packaging User Group has launched three new projects:

Large Footprint BGA Warpage. PCB warpage is a common phenomenon due to material CTE mismatch, copper distribution, PCB processes, etc. For large BGA footprints (e.g., >75mm square), extra warpage on the PCB surface and package warpage have been creating significant challenges to SMT (solder joint issues) due to the flatness mismatch between the PCB surface and package. This project focuses on flatness within the BGA footprint that is impacting assembly with the aim of defining a sustainable and achievable BGA flatness guideline.

READ FULL ARTICLEFTG Completes Acquisitions of IMI, Holaday Circuits

TORONTO – Firan Technology Group has completed its previously announced acquisitions of Holaday Circuits and IMI Inc. Completion of the deals, both of which were announced last year, was slowed by mandatory US regulatory reviews.

Further to the previous announcements made by FTG regarding these acquisitions, FTG has now attained the approval from the Committee on Foreign Investment in the United States (CFIUS) and all closing conditions have been met and both acquisitions are now closed.

READ FULL ARTICLECHIPS for America Outlines Vision for the National Semiconductor Technology Center

WASHINGTON, DC – The National Institute of Standards and Technology (NIST) released a paper outlining its vision and strategy for a National Semiconductor Technology Center (NSTC), a key component of the research and development program established by President Biden’s CHIPS and Science Act.

Congress appropriated funds for the creation of a national center to support and extend US leadership in semiconductor research, design, engineering, and advanced manufacturing and strengthen US competitiveness.

READ FULL ARTICLEQuanta Betting Big on Mexico

NUEVO LEÓN, MEXICO – Quanta Computer will invest a reported $1 billion in the northern state of Nuevo León, Mexican government officials announced in late May.

Governor Samuel García cited the nearshoring trend for the investment, saying the area expects an almost-ninefold increase in foreign investment in 2023.

READ FULL ARTICLEÉolane Launches Malaysian Subsidiary

PENANG, MALAYSIA – Éolane is launching a new subsidiary here, which will include a new factory to better serve its customers as closely as possible to their markets, especially those of the Asia-Pacific Economic Cooperation (APEC).

Éolane Malaysia’s new factory is planned to open at the end of the year, and will join Intel, Hewlett Packard (now Keysight Technologies and Agilent Technologies), Robert Bosch, AMD, Litronix (now Osram Opto Semiconductors), Hitachi (now Renesas), Clarion and National Semiconductor at Kulim Hi-tech Park.

READ FULL ARTICLEAPG Makes ‘Significant’ Investment in XLR8

SAN CLEMENTE, CA – XLR8 EMS in May announced a significant equity investment from American Pacific Group, a $1.2 billion private equity fund. The small-tier electronics manufacturing services provider said the investment, the terms of which were not disclosed, would be used to expand its facilities and capabilities.

Founded in 2013, XLR8 is a rapidly growing contract manufacturer of printed circuit assemblies with a core focus on speed and technology for commercial, AS:9100, ISO:13485, and ITAR customers. For the past five years, XLR8 has been recognized by the CIRCUITS ASSEMBLY Service Excellence Awards as a leader in its category for quality and dependability, as voted by its own customers, and for the past three years won the top honor of overall leader in its category.

READ FULL ARTICLESigmaTron Sells Majority Position of Wagz

ELK GROVE VILLAGE, IL – SigmaTron announced that it reached an agreement in late April to sell a majority position of its wholly owned subsidiary, Wagz, to Vynetic.

During SigmaTron’s preparations for its third quarter financial statements, it was determined that updated projections resulted in a triggering event for the company’s goodwill and long-lived asset groups, which would incur non-cash impairment charges of approximately $23.1 million. These impairment charges coupled with Wagz’ operating losses triggered a default with SigmaTron’s credit agreements with J.P. Morgan Chase Bank and TCW Asset Management Company. The company also received a delinquency notification letter from Nasdaq indicating that it was not in compliance with the continued listing requirements of Nasdaq for failing to timely file the Company’s Form 10-Q for the fiscal quarter ended January 31, 2023. That notification also constituted a default.

READ FULL ARTICLEISC Acquires MX Electronics’ Santa Ana Facility

SANTA ANA, CA – Interconnect Solutions Company, a provider of electromechanical and interconnect solutions, announced that it has acquired the Santa Ana-based assets of MX Electronics Manufacturing.

In a statement announcing the acquisition, ISC said the addition of MX Electronics’ assets adds capacity in many existing business lines, plus capability in printed circuit board assembly (PCBA) to better serve both existing and future customers. ISC is part of Tide Rock’s manufacturing portfolio.

READ FULL ARTICLEPCD&F

Accurate Circuit Engineering purchased an Excellon COBRA-II hybrid laser system.

Gold Circuit Electronics announced plans to set up a new plant in Thailand.

Mitsubishi Electric’s ME Innovation Fund invested in startup PCB maker Elephantech as part of a 900 million yen ($6.67 million) funding round.

Tianjin Pulin announced that the company plans to purchase 20% of the equity of Taihe Circuit Technology (Huizhou) held by TCL Digital Technology (Shenzhen).

Trackwise Designs has launched the sale process for its subsidiary, Stevenage Circuits, to focus on its harness technology business.

Yaohua announced plans to establish a subsidiary in Thailand, with a total investment of 1 billion baht ($29.6 million).

CA

Aculon named Ellsworth Adhesives global distributor of its NanoProof 3 series coating.

ASML will build a new research center including a clean room together with Eindhoven’s Technical University.

BPC purchased a Kulicke & Soffa wire bonder to support its expansion into sectors where battery packs are required, particularly EV OEMs.

Cetec ERP was recognized as a top cloud ERP provider for aerospace/defense distributors by Aerospace Export.

CommScope Tijuana purchased a ViTrox V810i x-ray inspection unit.

Read Full Article

PCD&F

mike tucker

nathan edwards

Confidee appointed Andrea Queirolo sales manager Italy.

Millennium Circuits named Mike Tucker director of engineering and technology.

The U.S. Partnership for Assured Electronics named Nathan Edwards executive director.

CA

Troy schlegel

charles lower

josef ernst

stacey jones

kenny wilson

corrine baker

sean park

Alert Tech SMT named Troy Schlegel director of production operations.

Altus appointed Charles Lower sales manager for the southwest region.

ASMPT SMT Solutions named Josef Ernst CEO, succeeding Guenter Lauber.

Hentec Industries/RPS Automation hired Stacey Jones as purchasing agent.

Jabil named Kenny Wilson its new CEO, succeeding Mark Mondello, and appointed Corinne Baker director of supply chain management.

StenTech appointed Sean Park western regional sales manager.

VivaQuant named Alex Zeitler director of manufacturing.

PCB East 2023 Registration Up 59% Year-over-Year

PEACHTREE CITY, GA – Registration for the PCB East 2023 conference and exhibits rose 59% overall from last year, the Printed Circuit Engineering Association announced.

Conference registration more than doubled, rising 110% from last year, while the expo-only trade show registration rose 63% over the same period.

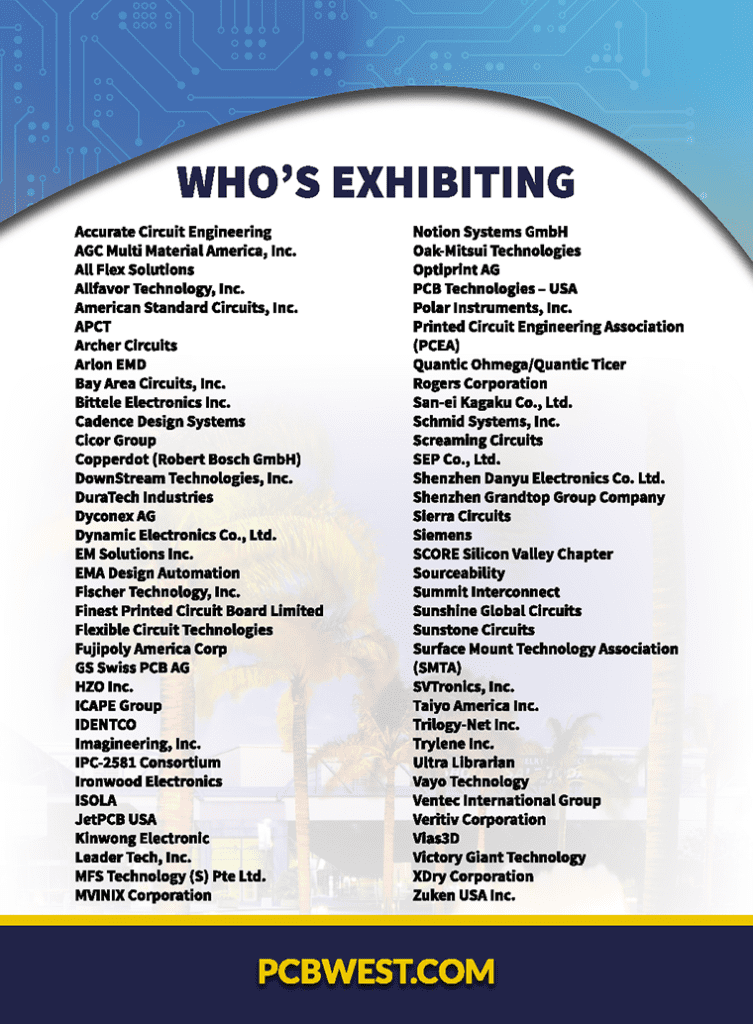

The annual trade show was held May 9-12 at the Boxboro Regency Hotel and Conference Center in Boxborough, MA. In all, more than 60 leading suppliers of electronics design tools, manufacturers of bare boards and assemblies, and suppliers of fabrication and assembly equipment and materials exhibited at the show.

National News

Conferences Task Group. The PCB West 2023 technical conference schedule is now available at pcbwest.com. This year’s conference features more than 120 hours of top-rank training from the leading names in electronics design and manufacturing. We will also have a special “Ask the Experts” session all day on Sept. 20, where you can get advice or just commiserate with gurus like Rick Hartley, Keven Coates, Mark Finstad and Nick Koop. Visit pcbwest.com for details.

EMI seminar. Rick Hartley will present a special live two-day workshop on “Control of EMI, Noise and Signal Integrity in High-Speed Circuits and PCBs,” coming June 20-21 to the Atlanta suburb of Alpharetta. As Hartley notes, EMI is a leading concern for electronics designers and a major cause of failures. The seminar has been updated to contain a fair amount of new information that was not taught in years past. Each attendee will receive a color PDF copy of the full slide deck. For details, visit pcb2day.com.

Chapter News

San Diego. Palomar Community College is offering a comprehensive online PCB design course, taught by John Watson. The classes include a 16-week beginner course and a 16-week advanced course, with the beginner classes starting on Aug. 22, 2023, and the advanced courses starting on Jan. 30, 2024.

The chapter has elected John Watson vice chair and Nick Maldonado communications director.

Electronics Supply Chain Coming into Balance in H2, Says Supplyframe

PASADENA, CA – Lead times and prices are expected to drop toward historical norms in the second quarter, while inventory reductions and corrections will continue into the second half of the year, according to the latest analysis from Supplyframe.

Consumer markets remain lethargic, but automotive and industrial segments are relatively robust. And macroeconomic shifts will have massive repercussions for the global electronics supply chain – with a demand rebound for PCs, smartphones, and data centers required to drive new growth.

“Despite global economic challenges and uncertainties, [our data] show that commodity supply-demand rebalancing is well underway,” said Supplyframe CEO and founder Steve Flagg. “Some electronics commodities and end markets have shown initial signs of recovery through Q1.”

Global electronic component sourcing activity rose 3.6% quarter-on-quarter, led by fiber optic component demand, which increased 22.1% and offered signals for potential demand rebounds, according to Supplyframe.

READ FULL ARTICLE

The Real Cost of Production

Manufacturing costs include more than just material, labor and overhead.

POSSIBLY IT’S BECAUSE inflation has ticked up over the past year or so, or possibly it’s because despite a long career in manufacturing, and I am still not sure all stakeholders from production, sales, customers, suppliers – and especially accounting – really understand or agree, but I find myself now more than ever trying to identify and come to grips with the “real cost” of what I produce.

I am hardly the first to ponder this question. Truth be told, I spent too many years early in my career performing standards engineering and being responsible for product costing. All that experience, I fear, has left me more a skeptic than an expert on product costing. Too many companies in our industry have ended up foundering, in no small part because of their leadership not understanding the real cost of their product.

Cost accounting 101 will teach you to consider material cost, labor and overhead. Yet it is the “other” costs that, in my experience, are far more significant and usually either not considered or undervalued as part of the costing equation. Supplies, required services, benefits and most of all, risk, all seem to get rolled into one of the basic three (materials, labor, overhead) rather than being understood and properly valued. So, let’s quickly run through all seven of them.

Materials. To fabricate a circuit board, laminate is needed, as is surface finish, processing films, etc., and these usually make it onto the bill of materials because they are relatively easy to quantitate and are needed to produce product.

Read Full Article

Pride in the Workforce

Are you tapping all the opportunities in your labor market?

FOR US ELECTRONICS manufacturing services (EMS) providers, the only thing in shorter supply than long lead-time components is labor. Decades of manufacturing job losses translate to a generation of workers who don’t consider manufacturing jobs because they don’t know anyone in manufacturing. EMS companies are addressing this in multiple ways including job enlargement for existing workers, greater use of automation and closer ties with community colleges. Flexible work schedules better aligned with college student or single-parent schedule preferences have also been successful tactics. In areas with large retired populations, flexible work schedules may also appeal to retirees who are feeling inflationary pressures to re-enter the workforce and want better compensation than found in retail.

Recently, I had a discussion with Andrew Williams, engineering manager at Pride Industries’ EMS operation in Roseville, CA. Pride Industries’ mission is to create employment for people with disabilities. Pride Industries was founded in 1966 in the basement of a church in Auburn, CA, by a group of parents of young adults with developmental disabilities who wanted their grown children to have purpose and experience the dignity of a paycheck. Today, Pride Industries operates across 15 states plus Washington, DC, and is the leading employer of people with disabilities in the nation.

Read Full Article

Thermal Considerations for Printed Circuit Board Designers

Leave more metal behind.

BEING COOL USED to be easy. Modern times call for a more comprehensive approach to keeping the lights on when it comes to our PCB layouts. The early days of electronics saw through-hole components bearing a single transistor that sat well above the board much like a water tower commands the skyline in a pastoral setting.

The device was free to blow off as much steam as required without scorching the stuff we call FR-4. Fun fact: Did you know that the FR in FR-4 stands for “fire retardant” and that 4 is the number of iterations that lead to the resin/glass combo that undergirds our industry’s history to this day? The material is rated by its ability to withstand high temperatures without breaking down.

One of the most important characteristics of FR-4 is the glass transition temperature, or Tg, where the material simply melts down and fails. It is measured in centigrade, and a working number is between 140° and 170°. That will not be sufficient for extreme environments and hard-working chips. There may be exceptions but you’re nominally looking at exotic dielectric materials that are meant to cater primarily to data centers and broadcast scenarios. The ancient art of ceramics plays a part in withstanding higher temperatures for devices and PCB laminates.

Read Full Article

MCAD-ECAD Co-design

A common component library aids engineering integration.

AS I MENTIONED in my column last month, PCB design best practices have five pillars. The first pillar, digitally integrated and optimized, is the foundation. It specifically addresses interactions within the design process and how multidiscipline and multidomain integration and collaboration should take place.

This leads me to pose a simple question: Is your engineering team digitally integrated and optimized when it comes to MCAD-ECAD co-design, or is it functioning with a legacy approach that contains many manual efforts/tasks while team members are working in silos?

Every PCB design starts with the design of the physical package/box (the system) where the PCB will reside. As this occurs, the physical features of the PCB are defined. These features include items such as the dimensions of the PCB outline; board thickness; mounting holes; tooling holes; restricted areas/rooms such as specific components’ height ceilings; component keep-ins and keep-outs; critical components such as connectors, heatsinks and sub-assemblies; plus any other pertinent critical features and or details.

Read Full Article

Reshoring or Resurrection?

The road to resilience for Western manufacturing must begin with small steps.

FOR MORE THAN three decades, leading electronics brands in the West have enshrined leanness, maximum efficiency and lowest cost. The drive to outsource manufacturing to areas where labor costs are lowest has enabled the industry to deliver more advanced electronic products at relatively affordable prices.

It has made perfect sense for the world’s OEMs, relieving demand for capital investment and helping to cut costs while giving access to cutting-edge processes and providing rapid, low-risk scalability. The trend to outsource began in the late 1970s and became the dominant model in the ’80s and ’90s. Throughout the 21st century, this has been the way to operate a competitive supply chain. Now, the largest EMS operations are based in China and Southeast Asia and the sector is currently worth about $800 billion. It’s still growing at more than 7% compounded annually.

But something else happened during this transformation. As production migrated geographically, the essential skills associated with designing and making advanced electronics products also moved away from the OEMs and became concentrated in Asia. Many associated industries also moved out. In the 1980s there were 23 full-scale manufacturers of substrate base materials in Europe. Currently, there are two. Similarly, the number of manufacturers of glass and copper foil has fallen from 12 to just one.

Read Full ArticleDatasheets, Unveiled

Smooth copper isn’t always what it is purported to be.

I ALWAYS TRUSTED datasheets. Why shouldn’t I? Every time I picked one up, I understood they were harbingers of truth about what something did and how to interact with it. From chips to components to widgets, manufacturers have a vested interest in ensuring users know what and how to use their products.

My trust in datasheets was eviscerated the very week I entered the printed circuit board industry. I was attending a weeklong training session on signal integrity taught by Eric Bogatin when he surveyed the attendees about datasheets and their accuracy. While my memory of the day and exact content isn’t perfect, I do recall that as the very moment I learned the harsh reality: Datasheets are sometimes not as accurate as one would hope! (As an aside, Eric Bogatin’s books on signal integrity are excellent resources because he has that special gift of teaching and explaining complex topics in approachable and understandable ways. The concept of “being the signal” and walking down a transmission line is just fantastic.)

Read Full Article

High-Speed Rigid-flex

Rigid-flex can meet the speed you need – with the right design and materials.

I AM DESIGNING a rigid-flex and was just told it will be higher frequency. What do we have to do differently?

Answer: As the phrase goes, “I feel the need…the need for speed!” We are seeing more and more applications with signal speeds in the GHz ranges. As clock speeds on chips increase, it is important for the circuit boards to keep up the pace.

When it comes to high speed, rigid-flex is very capable of meeting the challenge. It all comes down to good design and material selections.

For the high-speed signals, think in all three dimensions. Map out which layers carry these signals. Rigid and flex layers will have different dielectrics and copper types. If all the high-speed signals reside within the rigid layers only and do not span the flex region, concentrate just on those rigid layers and associated materials. For this discussion, however, let’s assume that one or more of the flex layers will be involved.

On the rigid layers, you may select from a wide range of rigid copper clad laminates as well as various copper profiles just as you would for a rigid PCB. Manage loss by selecting low-profile coppers and low-loss tangent laminate.

Read Full Article

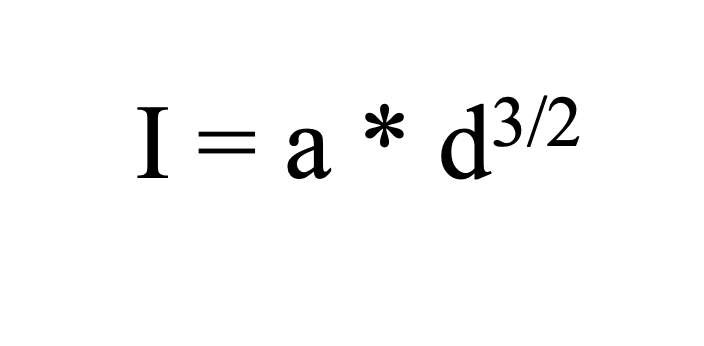

Onderdonk’s and Preece’s Equations: How Do They Compare?

Two unique equations can be used when fusing a trace – each offering its own strengths and weaknesses.

by DOUGLAS BROOKS, PH.D.

Up until about 10 years ago, when PCB designers searched for information about the current needed to melt a trace on their boards, only two names popped up in the literature, W. H. (Sir William Henry) Preece and I. M. Onderdonk. Each is credited with developing a unique equation, bearing their respective name, and those equations became the basis for many PCB calculations.

Preece’s background is considerably well known. In the 1880s, he was a consulting engineer for the British General Post Office and became engineer-in-chief in 1892. At that time, the Post Office was responsible for the telegraph (and later wireless telegraph) system in England. He published three papers in the Proceedings of the Royal Society of London in the 1880s that formed the basis for his famous equation1:

where d is the diameter of the wire in inches

a is a constant (10244 for copper), and

I is the fusing current in amps.

Interestingly, in the 1890s, Preece became an ardent supporter, both politically and financially, of Guglielmo Marconi and his work on trans-oceanic wireless telegraph.2

On the other hand, almost nothing is known about Onderdonk. I have found no earlier reference than a small article in a 1928 issue of the General Electric Review by E. R. Stauffacher.3 Onderdonk’s equation is referenced a few places in the literature, and it is always quoted as a “given” (much like we take Ohm’s law as a given.) I have found no original work by Onderdonk.

Read Full Article

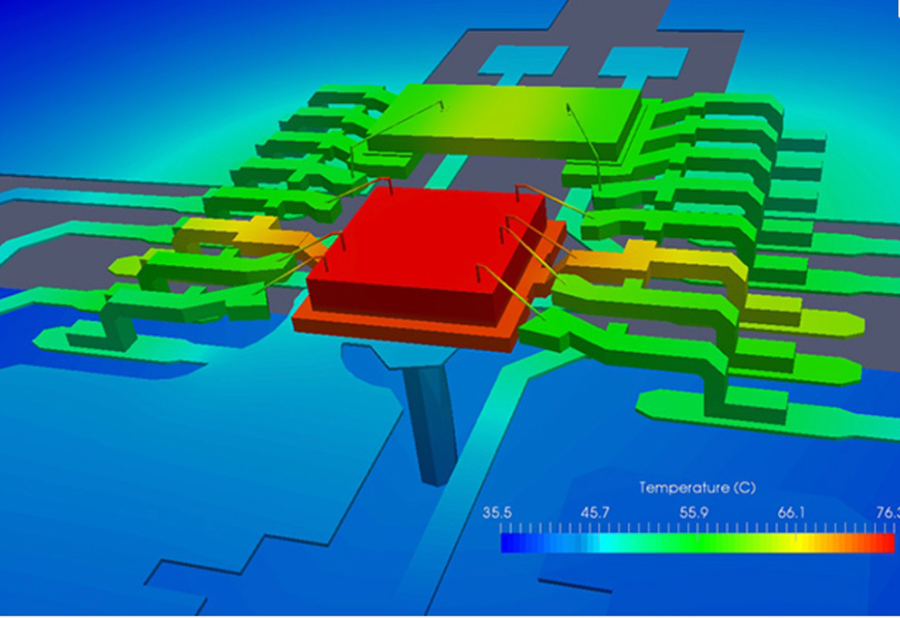

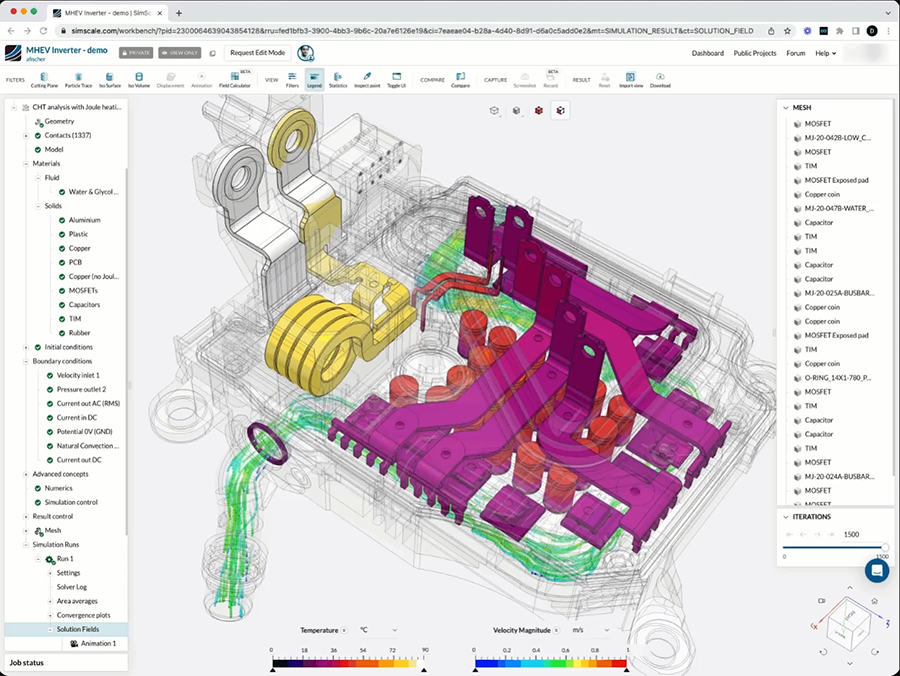

Simulating Electronics Components in the Cloud

Methods for assessing component temperatures and fan performance.

by ALEX FISCHER

Cloud technology has become increasingly prevalent, allowing use of 3-D models and numerical methods to analyze CAD models of electronic devices and components. Numerical computations of conduction, convection and radiation are essential for understanding how these heat transfer mechanisms can be utilized for effective cooling techniques.

Advantages of cloud-native simulation include fast and easy access in a web browser, the ability to explore a complete design space and eliminate poor design choices earlier in the development process, and the ability to import geometry without tedious CAD cleanup constraints. The mesh for Immersed Boundary Method (IBM) solvers, for example, is founded on a cartesian grid, making it resilient to geometrical features and obviating CAD simplification. The sheer limitless computing power and scalability of the cloud means sharing simulation capabilities across a full organization of geographically dispersed engineers is simple and easy. Engineers can perform cooling, heat and fluid flow analysis of electronic devices, PCBs, electronics systems and enclosures along with structural and mechanical assessment using a single CAD model, all in one simulation platform.

Cpk or Ppk? A Look at Using Both Capability Indices

Summary statistics can be misleading, but in different ways.

by Patrick Valentine, Ph.D.

Cpk and Ppk are numeric capability summaries of process or product characteristics based on common cause variation (due to chance) and assignable cause variation (special cause). Understanding these capability indices and their limitations is critical in pursuing world-class quality, “on target with minimal variation.” Cpk and Ppk indices are reviewed, and details on how to use them synergistically are provided.

Capability indices are numeric summaries that compare the behavior of a process or a product characteristic to customer specifications. Capability indices relate the customer specification limits (voice of the customer) to the natural process limits (voice of the process). Large index values imply that the process can produce parts that meet the customer’s specification limits. Small index values imply the process will likely produce some parts that will not meet the customer’s specification limits.

Process capability is a statistical measure of the inherent process variability of a given characteristic.1 Capability indices are convenient numeric summaries. These indices reduce complex process information to a single number. Capability indices are unitless values, and can be used to compare the capability of different processes. Most process engineers and quality managers believe capability indices less than 1.00 are unacceptable, and many process engineers and quality managers consider 1.33 a minimum acceptable value for capability indices. Capability indices ≥1.50 are generally considered world-class quality, “on target with minimal variation.”

Read Full Article

The West is Rediscovering India

The subcontinent explodes with new EMS work, prompting a spate of IPOs.

by MIKE BUETOW

Putting aside the obvious supply chain disruptions, the two big stories out of the EMS industry in 2022 were the emergence of India, led in particular by Apple’s pivoting from China, and the number of IPOs.

While the Indian government is aggressively recruiting foreign electronics investment, there’s no question India’s appearance as a viable competitor to – dare we say it? – China is being driven by Apple. The world’s most valuable company tripled its production to more than $7 billion of iPhones in what is now the world’s most populous country during the past fiscal year,1 mostly at the expense of China. Some reports hold Apple will raise India’s share of its production to 25% in two years.

One of the winners was Pegatron, which beat out Foxconn for the India orders, and is reportedly investing $150 million in a second iPhone manufacturing facility in Chennai.2 Luxshare, called little Foxconn by some, has also barged in, buying two of Wistron’s plans in India, and projecting unit sales to more than double to nearly 50 million units this year.

Not to be outdone, Foxconn will invest a reported $700 million on a plant in southern India to make telecom components and possibly iPhones.3

Read Full Article

The Printer and the Pea

Seemingly small issues can have big print implications.

MOST READING THIS column are probably familiar with “The Princess and the Pea” fairy tale by Hans Christian Andersen, wherein a tiny pea under 20 mattresses keeps a true princess from a good night’s sleep. Similarly, in the stencil printing process, seemingly small settings or interferences can prevent a good print outcome – particularly as assemblies continue to move toward higher densities and miniaturization. Our team had such a scenario recently while troubleshooting the cause for incomplete deposits on a complex board assembly.

This project involved printing on ultra-thin substrates – approximately 400µm thick. That’s about the thickness of a playing card, so very, very thin, which makes for challenging print stability. Moreover, the panel was on the larger side, about 400mm x 400mm made up of multiple PCBs with no routing, making it more difficult to ensure coplanarity during printing. Tooling stability is always critical and even more challenging with very thin substrates. Today’s tooling support solutions number a handful of options: Equipment standard tooling pins, reconfigurable pin systems like Grid-Lok, smart automatic pin placement, and dedicated tooling blocks with and without vacuum. Given the size and thickness of this substrate, our team used dedicated tooling blocks with vacuum to offer the most robust support for the process analysis.

Read Full Article

PCD&F

ALTAIR SIMSOLID CLOUD SIM TOOL

SimSolid Cloud structural simulation software allows access to simulation technology from any web browser anywhere, anytime. Eliminates geometry simplification and meshing, the two most time-consuming and expertise-intensive tasks done in traditional finite element analysis, and is said to deliver results in seconds to minutes while handling complex assemblies. Requires no software installation or extensive computing resources, and offers structural linear and nonlinear static, modal vibration, and thermal stress analyses in user’s preferred web browser. Features include mesh-free technology and full-fidelity CAD simulation, comprehensive physics support, adaptive solver technology, automated model connections, results in seconds, intuitive, user-friendly interface, and extensive material library.

Altair

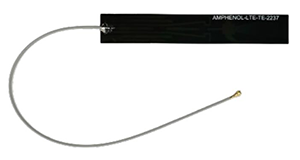

AMPHENOL RF INTERNAL ANTENNAS

Flexible and PCB patch antennas are for use inside connected devices and feature either a flexible pad or rigid PCB which can be mounted inside the device. Come in dual-band, multi-band and wide-band configurations with Wi-Fi 6E supported options with reliable frequency range up to 7.2GHz. Dipole design has a relatively low profile and can be mounted in various locations and supports standard cellular protocols, which makes them suited for IoT, Wi-Fi and LTE technology. Use center-fed micro-coax cables that terminate to an ultraminiature AMC connector and feature an adhesive mounting tape on one side for secure placement inside the device.

Amphenol RF

CA

ACCU-ASSEMBLY ACCULIFT REEL STORAGE

AccuLiFT SMT component reel vertical modular storage and retrieval system features a flexible reel configuration that enables small and large reels to be interchanged at any position on the pallet. Can store up to 3,900 7″ reels, with the ability to store up to 8,400 reels with two additional vertical storage units. Stores component reels on pallets constructed of a steel frame with ESD plastic trays. Vertical lift stores and retrieves parts, and expands vertically to conserve floor space. Uses Direct Drive Technology with auto correction requiring no calibration. Features a robotic, automated, dual-level operator reel loading/unloading station, allowing reel loading and unloading to take place simultaneously to reduce cycle time. Also includes automatic barcode scanning of all reels on the pallet, automatic reel thickness detection, and multiple job sorting capability. Optional features include the ability to print and place UID label on component reels and interface to x-ray component counters.

Accu-Assembly

AVEN MICROVUE 360 VIEWER ATTACHMENT

MicroVue 360 Viewer Attachment is designed for use with the line of MicroVue Digital Microscopes and offers a range of benefits for users who require enhanced precision and comfort during their work. Features a 35° angled mirror for looking around multilayered parts such as circuit boards, medical tools, industrial parts, and more. Also includes 360° rotation capability, for easy adjustment of viewing angle to achieve perfect line of sight.

Aven

In Case You Missed It

Additive Manufacturing

“Creating 3-D Objects with Integrated Electronics via Multiphoton Fabrication In Vitro and In Vivo”

Authors: Sara J. Baldock, et. al.

Abstract: 3-D objects with integrated electronics are produced using an additive manufacturing approach relying on multiphoton fabrication (direct laser writing). Conducting polymer-based structures (with micrometer-millimeter scale features) are printed within exemplar matrices, including an elastomer (polydimethylsiloxane, or PDMS) have been widely investigated for biomedical applications. Printing process fidelity in PDMS is assessed by optical coherence tomography, and the conducting polymer structures are demonstrated to be capable of stimulating mouse brain tissue in vitro. Furthermore, the applicability of the approach to printing structures in vivo is demonstrated in live nematodes (Caenorhabditis elegans). These results highlight the potential for such additive manufacturing approaches to produce next-generation advanced material technologies, notably integrated electronics for technical and medical applications (e.g., human-computer interfaces). (Advanced Materials Technologies, March 2023, https://onlinelibrary.wiley.com/doi/10.1002/admt.202201274)

Read full article