March 2023

PCEA

PO BOX 807

AMESBURY, MA 01913

PCEA BOARD OF DIRECTORS

Stephen Chavez, CHAIRMAN

Tara Dunn, VICE CHAIRMAN

Justin Fleming, SECRETARY

Gary Ferrari, CHAIRMAN EMERITUS

MEMBERS

Michael Buetow

Tomas Chester

Michael Creeden

Douglas Dixon

Richard Hartley

Scott McCurdy

Anaya Vardya

Susy Webb

Eriko Yamato

pcea.net

PUBLICATION

- PCD&F/Circuits Assembly digital.pcea.net

WEBSITES

- PCD&F pcdandf.com

- Circuits Assembly circuitsassembly.com

NEWSLETTER

- PCB Update pcbupdate.com

PODCASTS

- PCB Chat pcbchat.com

EVENTS

- PCB West pcbwest.com

- PCB East pcbeast.com

EDUCATION

- PCB2Day pcb2day.com

- Printed Circuit University printedcircuituniversity.com

AWARDS PROGRAMS

- Service Excellence Awards circuitsassembly.com

- NPI Awards circuitsassembly.com

pcdandf.com

DATABASE

- Directory of EMS Companies circuitsassembly.com

mike@pcea.net

frances@pcea.net

brooke@pcea.net

tyler@pcea.net

jacqueline@pcea.net

Clive Ashmore, Peter Bigelow, Robert Boguski, John D. Borneman, John Burkhert, Jr., Mark Finstad, Nick Koop, Alun Morgan, Susan Mucha, Greg Papandrew, Chrys Shea, Jan Vardaman, Gene Weiner

frances@pcea.net

brooke@pcea.net

frances@pcea.net

mike@pcea.net

jacqueline@pcea.net

PRINTED CIRCUIT DESIGN & FAB/CIRCUITS ASSEMBLY is distributed without charge to qualified subscribers. To subscribe, visit pcdandf.com or circuitsassembly.com and click on Subscribe.

For changes or cancellations to existing subscriptions: subscriptions@pcea.net

PRINTED CIRCUIT DESIGN & FAB/CIRCUITS ASSEMBLY is published monthly by Printed Circuit Engineering Association, Inc., PO Box 807 Amesbury, MA 01913. ISSN 1939-5442. GST 124513185/ Agreement #1419617.

© 2023, by Printed Circuit Engineering Association, Inc. All rights reserved. Reproduction of material appearing in PRINTED CIRCUIT DESIGN & FAB/CIRCUITS ASSEMBLY is forbidden without written permission.

Cynical Forecasters Might Want to Lay Off

We headed to IPC Apex Expo in late January not certain of what to expect. The backdrop, of course, was one of job upheaval. Blue chip tech companies were announcing large-scale layoffs, and the “disengagement” counts were starting to accumulate in striking fashion. To wit:

- HP: 4,000 to 6,000

- Dell: 6,650

- Google: 12,000

- IBM: 3,900

- Meta: 11,000

- Microsoft: 10,000

- Twitter: Everyone except Elon Musk and a couple of engineers brought over from Tesla*

This wasn’t wholly unexpected. Inflation, while trending down, remains stubbornly higher than pre-Covid levels. Fourth quarter sales slowed at many firms. The cost of money has ticked up for months. Companies have been hiring like mad for several years and what goes up – or in this case, out – eventually comes down, or in, at least somewhat.

Nevertheless, some of this seemed proactive, a rebalancing coupled with expectations that growth would abate in the coming year.

READ FULL ARTICLECIRCUITS ASSEMBLY Opens Registration for 2023 Service Excellence Awards

PEACHTREE CITY, GA – CIRCUITS ASSEMBLY has opened registration for its annual Service Excellence Awards (SEAs) for EMS providers and electronics assembly equipment, material, service, and software suppliers.

Now in its 31st year, the SEAs honor companies for excelling in the critical area of customer service, permitting participants to benchmark customer service against their peers. It is the only industry awards program that uses direct customer feedback to determine best-in-class.

The deadline to enter is Mar. 15.

READ FULL ARTICLETTM Technologies to Close 3 Manufacturing Facilities

SANTA ANA, CA – TTM Technologies announced in February that it will close three PCB manufacturing operations in Anaheim and Santa Clara, CA, and Hong Kong, and plans to consolidate the business from these sites into its remaining facilities.

TTM said it expects to close the three sites over the course of this year, and while some employees will be transferred to nearby facilities, the company said it expects a total reduction of approximately 750 employees, or around 5% of its global workforce.

The company said it expects to see between $22 million and $28 million in separation, asset impairment and disposal costs related to the closures, and projects an annual profit increase of around $22 million to $27 million after the facilities are closed and operations are consolidated within its remaining footprint.

READ FULL ARTICLEIcape Group Ends Operations in Russia

FONTENAY-AUX-ROSES, FRANCE — PCB supplier Icape Group announced it is ending its operations in Russia.

In a statement released by the company, Icape said it had decided to terminate its Russian operations and stopped taking orders on Jan. 1. Negotiations on the condition and exit of the company’s assets are underway and should be concluded as soon as possible, and the withdrawal from Russia should not have a significant impact on revenue and results, the company said.

MKS Instruments Investigating Ransomware Attack

ANDOVER, MA – MKS Instruments is investigating a ransomware attack that occurred in early February and affected its production-related systems.

In a filing to the SEC, the company said it had temporarily suspended operations at some of its facilities as part of the effort to contain the attack. MKS said it is working to complete its investigation and restore the company’s systems and impacted operations as quickly as possible, and the full scope of the costs and impact from the attack is not yet known.

Camelot Electronics Tech Plans $340M Expansion

QINGYUAN CITY, CHINA – Camelot Electronics Technology plans to invest around $339 million to expand its printed circuit board fabrication operations.

The fabricator, whose clients include Huawei, ZTE, Siemens, Honeywell and ABB, mainly focuses on the automotive PCB market. Its products are used in Tesla, BMW, Audi, Mercedes-Benz, NIO, Xiaopeng, Volkswagen, Toyota, Chrysler, Nissan, Peugeot-Citroen, Hyundai, Yutong, Geely and other automotive brands.

Camelot has two production bases in Qingyuan and Anlu, Hubei Province, and plans to form PCB production capacity of 5.2 million sq. m. per year. The production base in Qingyuan is 40,000 sq. m. with a production capacity of 1.2 million sq. m. per year. The Anlu site is 261,000 sq. m. and has an annual production capacity of 4 million sq. m. HDI (high-density interconnection) and rigid-flex PCBs.

ECIA GIPC Publishes Report on Paperless Certificate of Compliance Initiative

ATLANTA – The Electronic Components Industry Association’s Global Industry Practices Committee (GIPC) in February published a report outlining the results of a two-year initiative to create a streamlined process to digitally exchange manufacturer Certificate of Compliance documents. Analog Devices Inc. (ADI) agreed to participate in the pilot project with Digi-Key. They began with the manufacturers’ certificate of compliance while considering other compliance documents. The report from this initiative is available to industry.

The process for the exchange of compliance documentation in the electronic component supply chain is cumbersome and inefficient as it is still largely done manually. Compliance documents are currently in paper form and must accompany the components when shipped from the manufacturer to the distributor and on through to the end-customer. This, says GIPC, drives unnecessary costs with manufacturers, distributors and customers in the form of time and effort spent locating and tracking paper documents and the actual costs of printing and handling them. Throughout the supply chain, those responsible for complying with these requirements are dissatisfied and frustrated with this inefficient process.

READ FULL ARTICLEArtaflex Acquires Custom Rapid Solutions

TORONTO – EMS provider Artaflex has aquired Custom Rapid Solutions, a provider of quickturn PCB assemblies in the Toronto area.

“CRS has been manufacturing quickturn PCBs, as well as low- to medium-volume production, in the industrial segment since 2005 and has a reputation for delivering timely and quality service to its long-standing customer base,” said Gerry Iuliano, EVP of business development, Artaflex. “When you couple the addition of five SMT lines from CRS and their focus around power, sustainable/renewable energy and the industrial automation markets with our focus on higher-volume PCB assembly, box build, systems integrations and test (SIT), our new combination will be offering the most comprehensive suite of services in the Southern Ontario region.”

READ FULL ARTICLEGuh Holdings Expands into EV Business

PENANG, MALAYSIA – In a move to broaden its revenue base, PCB maker Guh Holdings is expanding into the electric vehicle business with the recent acquisition of a 70% stake in Star Wheels Electronics, a company involved in the sales, distribution, manufacturing, assembly and repair of electric scooters, hoverboards and spare parts.

“Star Wheels generates RM2 million ($459,000) to RM3 million ($689,000) sales per annum. The company has nine sales outlets in the country and distributors in the Philippines and Australia,” Guh managing director Datuk Seri Kenneth H’ng told StarBiz about the RM2.1 million ($483,000) transaction.

READ FULL ARTICLEStenTech Acquires Advanced Tooling Design

CLEVELAND – StenTech has acquired fellow stencil and fixture designer Advanced Tooling Design for an undisclosed amount.

ATD designs and manufactures stencils, tooling, fixtures and related accessories used in the electronics assembly industry, with applications across a range of end-markets. Headquartered in San Jose, ATD expands StenTech’s facility footprint into California, the largest market for stencil and pallet manufacturing in the US.

READ FULL ARTICLENiche Electronics Purchases L-Tronics

SHIPPENSBURG, PA – Niche Electronics, an electronics manufacturing services company based in south-central Pennsylvania, has announced the purchase of Waltham, MA-based L-Tronics. Terms were not disclosed.

Founded in 1990, L-Tronics manufactures printed circuit assemblies, wire harnesses, and OEM electrical mechanical devices. The integration of L-Tronics’ 8,000 sq. ft. facility and 30 employees will equip Niche with redundant sites in three geographical locations, making it able to shift production in the event of service interruptions from machine outages, natural disasters, fires or other unforeseen circumstances, the company said in a release.

READ FULL ARTICLEÉolane Begins Operation of New Factory in China

SUZHOU – Éolane has opened a new 4,000 sq. m. factory here to serve its customers in the industrial, medical and rail sectors – particularly CRRC, a major Chinese rail company.

The company inaugurated the factory in November after seeing growth of more than 21% in 2022, and the expansion brings the total surface of its factories in China to 11,500 sq. m.

“The construction of our new production site in China demonstrates our ability to remain at the forefront of all technologies in order to provide the best quality of service to our customers, as close as possible to their needs.

READ FULL ARTICLEBonfiglioli Acquires Selcom Group

BOLOGNA, ITALY – Bonfiglioli, a manufacturer of drive systems, gearboxes and inverters, has announced an agreement to acquire Selcom Group, an Italian producer of PCB assemblies.

Selcom employs around 750 employees across four production plants in Italy and two plants in Shanghai. The acquisition of Selcom Group is meant to strengthen Bonfiglioli’s electronic core and will increase the company’s development capacity, Bonfiglioli said in a release.

READ FULL ARTICLEAustin American Technology Merges with Aqua Klean

AUSTIN, TX – Austin American Technology and Aqua Klean Systems will merge, the companies said in a joint statement. Operations will continue at the firms’ existing facilities in Austin and Anaheim, and all employees will be retained. Financial terms were not disclosed.

Austin-based AAT has developed equipment for printed circuit board cleaning, surface-mount technology, stencil and misprint, flip chip, BGA and other cleaning applications for more than 35 years. Founded in 1996, Anaheim-based Aqua Klean assembles cleaning systems for virtually any process.

READ FULL ARTICLELorom Acquires Segue Manufacturing Services

TAIPEI – Lorom Holding Company, a manufacturing solutions provider focusing on specialized cable manufacturing and assembly, in February announced the acquisition of Segue Manufacturing Services. Terms of the acquisition were not disclosed.

Segue is a global contract manufacturer specializing in complex electromechanical integration, cable, and harness assembly and engineering services for the medical, industrial automation, capital equipment, and device OEM end-markets. The company has manufacturing operations in in Billerica, Massachusetts; Xiamen, China; and Monterrey, Mexico.

READ FULL ARTICLEIcape Acquires Fimor Electronics

FONTENAY-AUX-ROSES, FRANCE – Icape Group in February acquired Fimor Electronics, a French manufacturer of human-machine interface solutions and distributor of custom-made technical parts.

Fimor Electronics specializes in the trading of custom-made technical parts, an activity that represents 80% of its revenue, and also owns a factory specializing in the manufacture of human-machine interface solutions, which is the company’s second activity and generates 20% of its annual revenue. The company has a portfolio of 350 customers, mainly in the medical, automotive, high-tech and telecommunications sectors. The company also includes a service office in Foshan, China, in charge of commercial and technical relations with about 10 suppliers at the local level. In 2021, Fimor Electronics generated a net annual revenue of more than €6.2 million ($6.6 million) and EBITDA of €600,000 ($642,000).

READ FULL ARTICLEFoxconn Secures Manufacturing Site in Vietnam

TAIPEI – Foxconn has signed a $62.5 million lease with Saigon-Bac Giang Industrial Park Corp in Vietnam to build a new manufacturing facility.

The move to secure a new manufacturing site comes after the Apple supplier’s iPhone plant in Zhengzhou, China, saw an exodus of tens of thousands of employees and violent worker protests amid stringent pandemic control measures imposed during a Covid-19 outbreak that began in late October.

The Vietnamese site, located in the Bac Giang province east of Hanoi, was rented through Foxconn’s subsidiary Fulian Precision Technology Component Co. The lease will run through February 2057, the company said.

Foxconn previously announced that it will relocate some of its MacBook production to Vietnam, and has also announced plans to quadruple the workforce at its iPhone plant in India over the next two years.

PCD&F

Altair has signed a multiyear campuswide license agreement with TU Delft, the Netherlands’ oldest and largest public technical university which is ranked 10th for engineering and technology in the QS World University Rankings.

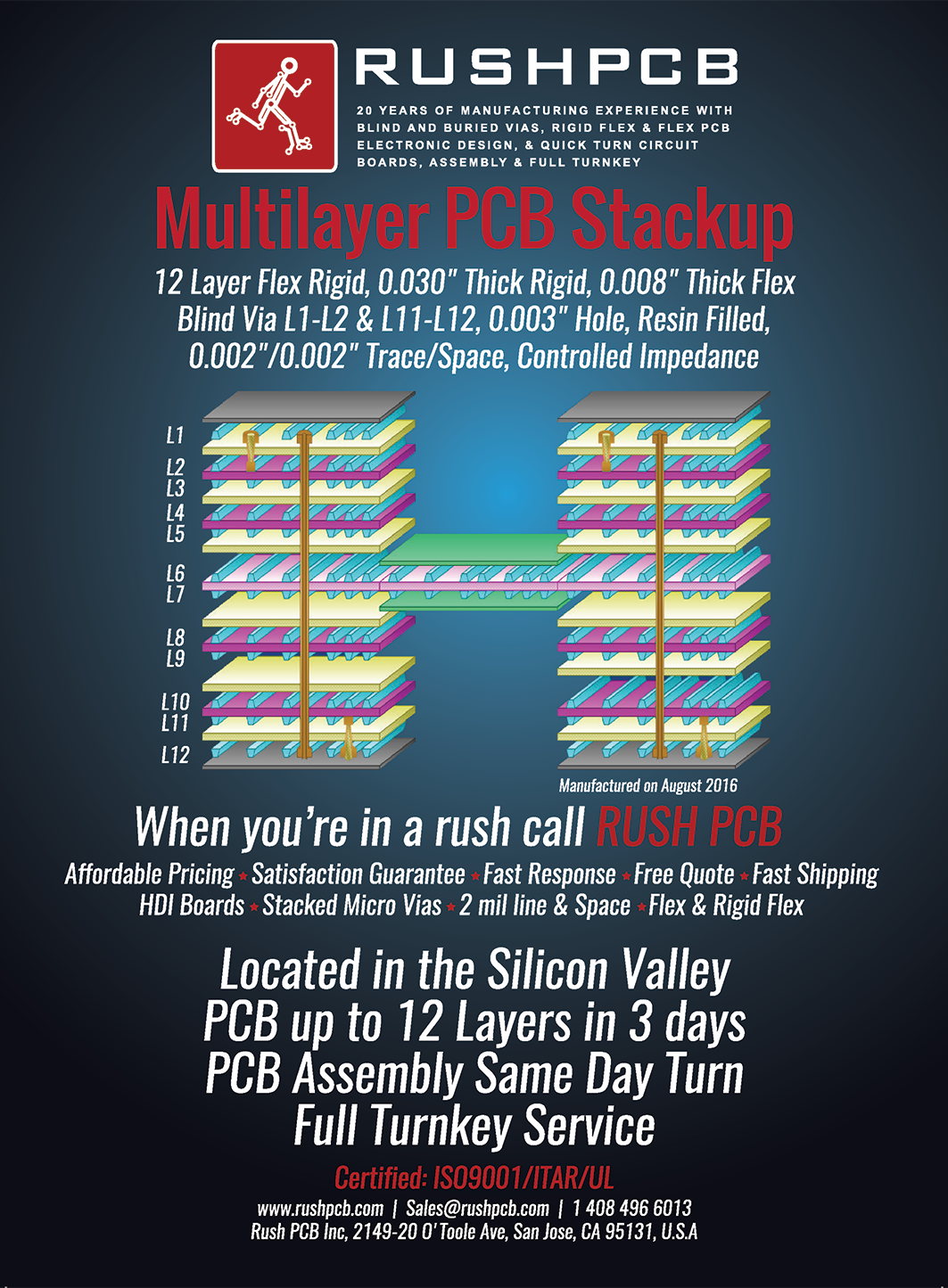

Compass Diversified in February completed its previously announced sale of Advanced Circuits to APCT.

Nano Dimension received a purchase order from a supplier to the US government defense industry for a DragonFly IV additive manufacturing 3-D printer.

Read Full ArticleCA

Altest purchased 10 Tagarno digital microscopes for its PCB assembly manufacturing facility in San Jose.

APCT has purchased a Hentec Industries/RPS Automation Pulsar solderability testing system.

ASMPT upgraded its WORKS smart shopfloor management suite with a Material Demand Calculation to dynamically calculate material requirements for definable time intervals, taking all incidents into account and continuously adjusting material requirements.

Read Full ArticlePCD&F

Alpha Circuit named Matt Kehoe southern US sales manager.

Freedom CAD Services announced Dan Amiralian as chief strategy officer.

Gardien Group named Rick Meraw president.

Vince Valeri, cofounder of Dynamic & Proto Systems, has passed away.

Pakistan Detectors Technologies named Samina Khalid printed circuit board design engineer.

Quantic Ohmega named John Andresakis director of business development.

CA

ACDi named Tom Dykeman vice president of sales.

Advanced Instruments promoted Joe Perault to director global operations.

AIM Solder appointed Mehak Sharma Canadian national sales manager. AIM also named Andrew Coleman regional sales manager for the US Midwest.

BEST named Nash Bell president, replacing Bob Wettermann, who is retiring.

Foxconn has appointed Michael Chiang as the new boss for its iPhone assembly business.

Nanocoating Webinar, Flex Circuit Presentation Highlight Upcoming Meetings

PCEA in April will host a free webinar titled “Engineered Reliability: Safeguarding Electrical Components and Devices with Nanocoating Technology” by Richard Weiland, director of Nanocoating Applications for HZO Inc.

Thin-film nanocoatings can protect critical electronic circuitry that is used throughout a variety of applications and can be a powerful solution to implement to ensure reliability. Only requiring nanometers- to microns-thin coating, plasma-enhanced nanocoatings are dense, highly cross-linked, multilayer films that create a physical and chemical barrier around components to enable an envelope around the circuitry at a molecular level. The result is dependable functionality in harsh environments that may include moisture, sweat, etc. Plasma-enhanced nanocoatings leverage various liquids and gas chemistries to provide fast deposition cycles that are repeatable and scalable to projects of different sizes, use environments, and performance standards.

Read MoreChapter News

Orange County. In February, the Orange County Chapter held a Lunch ’n Learn meeting, exploring advances in the technology of embedding resistors and capacitors which can benefit many designs today.

Bob Carter, vice president of business development & technology at Oak-Mitsui Technologies, spoke on embedded capacitance and improved power delivery. He provided an overview of the different types of embedded capacitance as well as fundamentals of power distribution network design for high-speed digital circuits. The talk covered how it is used in various types of practical applications such as MEMs and RF modules. Using ultra-thin power and ground plane pairs as embedded capacitance layers provide superb electrical performance with regards to charge delivery. There are particular benefits for reducing or mitigating noise and improving logic transitions. Performance, manufacturability, reliability and cost analysis were discussed.

Read MoreTPCA Advises Caution for Global PCB Outlook in 2023

TAIPEI – After growing 3.2% to $88.2 billion, negative factors like geopolitics, high inflation and high inventories will likely dampen the global PCB industry for at least the first half of 2023, according to the Taiwan Printed Circuit Association.

Continued chip supply uncertainty meant IC substrates became the counter to negative factors and even the engine for growth in Taiwan, Japan and South Korea. Strong demand from high-performance computing and further upgrades to end-user product specifications all factored in the global PCB market outperforming end-user sales. PCB makers such as Ibiden, Shinko, SEMCO and LG-Innotek saw chip carrier sales account for over 90% of their PCB business, meaning carriers accounted for almost all growth by Japanese and South Korean peers. On the other hand, Chinese companies that once enjoyed rapid growth all experienced a noticeable slowdown in gross profit margins and net profits due to their focus on other products.

READ FULL ARTICLEChanging of the Guard

The industry’s next generation is on the rise.

I am continually amazed at how many people I see and run into at each industry meeting or event – especially at technical meetings when I’m watching people leave one room and enter another for the next session. It strikes me a bit like watching the changing of the guard at Buckingham Palace – people leave one room to enter the next to do the same thing, and repeat!

One thing that makes our industry so strong and enduring is having so many people work together to contribute to developing and refining technologies, writing standards for those technologies and processes, and sharing their knowledge with others to fully understand those technologies and standards. And then as they say, “repeat.”

Read Full ArticlePCB Outline Transfer

Tips for better communication and preparation.

The PCB designer is often the recipient of a file or series of files that provide the working parameters of the board. These documents will come from a physical designer who does the mechanical engineering for the project. In some cases, the PCB designer wears that hat themselves.

When the PCB outline is straightforward, do it yourself. One-off test jigs come to mind. We’re probably working with a rectangle that provides ample real estate for the intended circuit. There will be room to grow and iterate, but also space for plenty of text to ease setup and debugging. Put a hole in each corner so standoffs can be installed to raise the board above the test bench.

While we’re at it, larger boards may require a stiffener that prevents flexing, which can put a strain on the solder joints. Additionally, wireless sections of the PCB require a shield to keep outside signals from affecting the radio. You may be asked to come up with drawings for those shield walls and fitted lids. The bigger picture requires a different perspective from what we use at the board level.

Read Full ArticleElectric Aviation Takes Flight

Effective electrification could hold the keys to the future of air travel and air superiority.

Many feel our lives enriched by convenient and fast mobility. Our societies and economies have become dependent on the ability to get places quickly in planes, trains and automobiles, but easy mass access to air and road travel now appears at odds with the survival of the planet. We need a zero-emission solution if we are to continue enjoying its benefits, and electrification based on renewable energy appears to offer a way forward. Adoption of electric vehicles is accelerating while development of the internal combustion engine for private automobiles has all but stopped. But what are the prospects for electric aviation?

As in the automotive world, the electric aviation landscape is populated by established aircraft constructors looking to protect their position and high-tech startups seizing the opportunity to disrupt. In the second category, the aptly named Eviation accomplished a first demonstration flight of its Alice full-electric plane in September 2022. As a nine-seater commuter, Alice is a potentially serious commercial proposition – perhaps one of the first. The demo lasted eight minutes, flying at up to 3,500 feet, which compares well with the Wright Brothers’ 12-second flight at Kitty Hawk in 1903. We have come a long way since then.

Read Full ArticlePermittivity vs Permeability: What’s the Difference?

Some areas of physics have considerable impact on PCB designs.

by Douglas Brooks, Ph.D.

PCB designers have had exposure to electronics (some more than others). And most of what we do falls under the field of electronics. But designers often have little or no exposure to physics. And some areas of physics have considerable impact on our designs. Here we look at two physical properties of the dielectrics we work with, and why they are important to understand (Note 1).

Permittivity. Why are some capacitors able to store much more charge than others? What is the relative dielectric coefficient associated with dielectrics and why does it matter? The answer relates to a property called permittivity. Before we get too far into this topic, we need to clarify some terms.

Dielectric constant is an out-of-date term that means the same as permittivity, εm. The permittivity of a vacuum, ε0, is given as 8.85418782 x 1012 Farads/meter. The relative dielectric constant, εr, or relative permittivity, is the ratio of the material permittivity to the permittivity in a vacuum, or

Read Full Article

How Interconnects Work: Characteristic Impedance and Reflections

Understanding reflections caused by transmission line characteristic impedance and termination impedance mismatch.

by Yuriy Shlepnev

Analysis of “digital interconnects” is the analog problem in frequency domain where interconnects are simulated as transmission lines defined by characteristic impedance and propagation constant. Digital signals in interconnects are sequences of amplitude-modulated pulses that transmit bits between components. The “digital interconnect” analysis problem is technically an analog problem of pulse propagation modeling in time-domain. The sequence of the transmitted bits (1s and 0s) is the only boundary between the digital and the analog interconnect analysis domains. That time-domain analysis problem, however, is practically always solved in the frequency domain. The pulse or sequence of pulses are transformed into a superposition of harmonics or sinusoidal signals in the time domain (more on that in Shlepnev1) because it is mathematically easier and more convenient to model all types of signal degradation for the harmonic signals using phasors and complex analysis. Components on PCBs in the digital domain are just connected – 1s and 0s are supposed to flow seamlessly among the components. In the analog or RF/microwave domain, components on PCBs or in a package are connected with the distributed open waveguiding structures composed of traces and reference conductors and simulated mostly as transmission lines. To ensure the digital signal gets through, we build interconnect models that include all signal degradation factors important for a specific data rate.

Read Full ArticleA Quick Fix for Fillet Starvation

Not enough solder? Blame the via design!

by AKBER ROY

Vias in pads can be “solder thirsty” and suck up solder from pads at terminals during reflow, creating what may appear to be solder insufficiency at the joints. This problem is typical of a via-in-pad design. It’s unpredictable as well; solder will randomly tend to fill those vias during the reflow process and some locations may appear worse than others, for example.

With a via-in-pad design, solder paste printed through an aperture of normal dimensions for the “toe” end of a pad at a rectangular end cap connection (FIGURE 1) may not provide enough solder during reflow to make a good solder fillet. The fillet may appear to be “starved,” because much of the solder that should be available to form a good solder joint will have wicked down the via and away from the end cap. The volume of solder lost will vary with the size and length of the via, the size of the component’s solderable surface(s) area, and other factors.

Read Full ArticleCIRCUITS ASSEMBLY NPI Awards Highlight Best New Products

CIRCUITS ASSEMBLY in late January announced the 2023 New Product Introduction Award winners for electronics assembly equipment, materials and software.

The 16th annual NPI Awards recognized leading new products during the past 12 months. An independent panel of practicing industry engineers selected the recipients. The awards were presented during a ceremony in San Diego.

The 2023 winners are:

Read Full ArticleGood Signs: IPC Apex Booth Traffic Suggests Busy Year Ahead

Exhibitors hope new products will keep the order books filled in 2023.

The good times of 2022 carried over into January as the industry turned out for one of the larger IPC Apex Expo trade shows in some time. The San Diego Convention Center show floor was humming for the better part of the first two days of the three-day event, and most of the more than 300 exhibitors seemed pleased with the attendance.

Most companies, in particular the assembly equipment suppliers, reported strong bookings for the quarter. Several added that they’ve raised their full-year forecasts as result of the surge.

A few years ago, there was a big push toward the connected factory. The branding and implementation of the machine-to-machine standard known as Connected Factory Exchange, or IPC-CFX, is now so ubiquitous, it was barely mentioned throughout the week.

Read Full ArticleAligning Six Sigma Tools with Process Reality

Identify the areas of variance in stencil design and adjust SPI programming accordingly.

Automated inline solder process inspection (SPI) has the potential to deliver some of the highest value among all inspection steps because defects caught at this point in the process require minimal rework. It is simply a matter of cleaning solder paste off the printed circuit board (PCB). Additionally, good printing performance typically represents 80% of a successful SMT assembly process. As the bulk of workmanship-related defects tend to track back to deficiencies in solder paste deposition, closely monitoring control limits in this area has a substantial impact on eliminating defect opportunities.

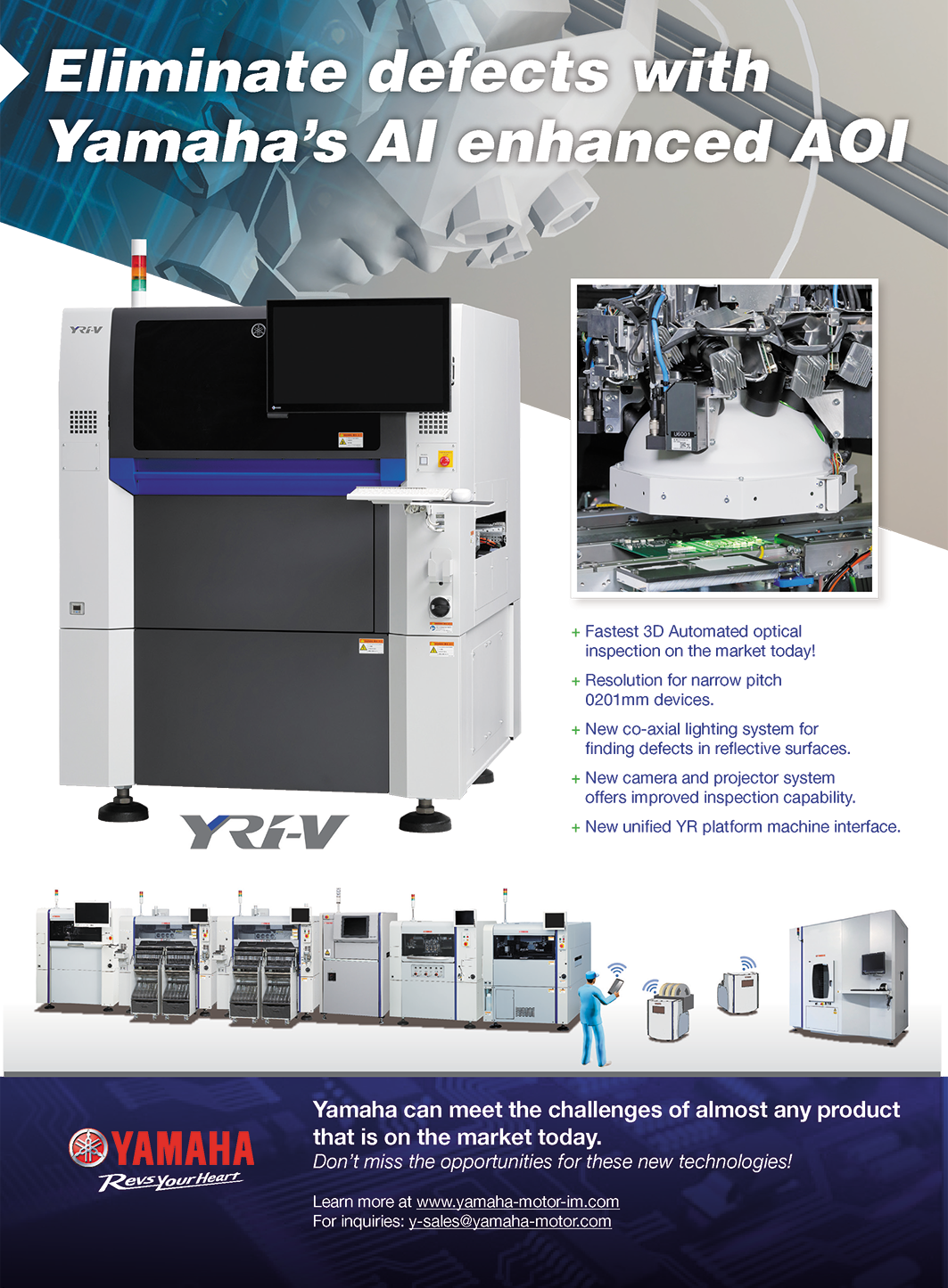

Industry 4.0 technology, which connects production equipment and enables automatic correction based on trends data from SPI or automated inspection (AOI) equipment, opens the door to even better process control. As inspection imaging technologies have improved from 2-D to 3-D, the focus on solder paste inspection has gone from paste height to measurements which include volume and area as part of good process control.

Automated inspection equipment is only as good as its programming, however. As a result, variations in stencil design created to address design for manufacturability (DfM) considerations can create issues in the way SPI equipment calculates process capability.

Read Full ArticleMom and Pop’s Revenge

Don’t underestimate the speed and execution of a smaller shop.

Def.: Mom and Pop Shop. A common characterization of a family-owned company, usually small, closely held, and tightly run under original or second-generation ownership; often used as a term of derision or condescension by members of large companies; unsophisticated, provincial, or parochial; perceived as lacking in the most current skills, tools, or manufacturing methods. Often viewed as predisposed to surviving as a business and ensuring family succession first, with growth for growth’s sake a secondary priority. Not innovative. Inflexible in business practices. Rarely for sale. Content to operate in their space. Stuck in their ways.

Your operation? Or perhaps someone’s cursory impression of it? Certainly you have heard someone belittle a company by saying, “They’re nothing more than a mom-and-pop operation.” How did you as an owner feel when you got wind of that summary judgment? Was your comeback equally dismissive and snap-judgmental (“Typical remarks by someone who’s never met a payroll in their life”)?

Console yourself that you know what you know. You’re here, actively and successfully participating in your local economy and our industry. You know you’d go crazy in a big company. The politics, the backbiting, the petty rules, the busywork, the layers of approval needed to get anything done, and the pointless mandatory “enrichment” sessions. Not for you. You’re unemployable in that environment. Which in a strange way may also be consoling.

Read Full Article

PCD&F

Altium Designer 23.1

Designer 23.1 offers improved features spanning PCB design, product design and data management, enabling creation of more detailed harness layout drawings, saving and loading a customized view of the board, and utilizing new capabilities within comments on the design. Schematic capture improvements include compiled names of power ports, which enables the Net Labels option in the Compiled Names Expansion region of the Schematic – Compiler page of the Preferences dialog to now determine the name for a Power Port object on the compiled (physical) tab of a schematic document. Net Labels option in the Print dialog (when accessed from an Outjob file for a schematic print output with the [Project Physical Documents] option selected as the output’s data source) and on the Structure Settings page of the Smart PDF Wizard also now defines how power ports will be shown in the schematic outputs. PCB design improvements include the ability to load a stored view configuration file from the View Options tab of the View Configuration panel, as well as the ability to rename the Gerber Board Outline type file in the Gerber Setup and Gerber X2 Setup dialogs. Also features improved callstack crash report content by using an enhanced method to collect callstack crash reports, and adds the ability to attach images to comments. Crimps can now be used on the Wiring Diagram (*.WirDoc) as was previously available in Layout Drawing, and parameters have been added to Twist and Shield objects in a Wiring Diagram document.

Altium

CA

AIM Zero-Halogen Solder Paste

Zero-halogen solder paste features improved electrochemical reliability, powerful wetting and exceptional fine-feature printing. Is for automotive, LED and aerospace assemblies and offers a robust, stable, and easy-to-implement product.

AIM Solder

Aven Mighty Vue Inspector

Mighty Vue Inspector is a magnifying lamp and camera inspection system in one self-contained unit. Allows image viewing directly on an HDMI monitor, captures and stores images on the included microSD Card, and connects to PC for viewing or relocating saved images. Features adjustable color temperature (3500K-6500K) and brightness control, and ESD-safe magnifying lamp dissipates electrostatic discharge.

Aven

In Case You Missed It

Electrochemical Migration

“Effects of Concentration of Adipic Acid on the Electrochemical Migration of Tin for Printed Circuit Board Assembly”

Authors: Yi Sing Goh, et al.

Abstract: Continuous advancement in innovative electronic applications leads to closer interconnection spacing and higher electric field density, thus increasing the risk of electrochemical migration (ECM)-related failures. The ECM of tin (Sn) attracts great interest due to the wide use of Sn on the surface of the printed circuit board assembly. In this work, the authors investigated the effects of adipic acid (1 ppm–saturated concentration) on the ECM of Sn using the water drop test (WDT) at 5V. In situ observation and ex situ characterization of ECM products were carried out using optical and electrochemical techniques. Results show that the ECM failure probability is higher at intermediate adipic acid

Read Full Article