September 2023

PCEA

PO BOX 807

AMESBURY, MA 01913

PCEA BOARD OF DIRECTORS

Stephen Chavez, CHAIRMAN

Justin Fleming, SECRETARY

Gary Ferrari, CHAIRMAN EMERITUS

MEMBERS

Michael Buetow

Tomas Chester

Michael Creeden

Douglas Dixon

Richard Hartley

Scott McCurdy

Anaya Vardya

Susy Webb

Eriko Yamato

pcea.net

PUBLICATION

- PCD&F/Circuits Assembly digital.pcea.net

WEBSITES

- PCD&F pcdandf.com

- Circuits Assembly circuitsassembly.com

NEWSLETTER

- PCB Update pcbupdate.com

PODCASTS

- PCB Chat pcbchat.com

EVENTS

- PCB West pcbwest.com

- PCB East pcbeast.com

EDUCATION

- PCB2Day pcb2day.com

- PCEA Training pceatraining.net

- Printed Circuit University printedcircuituniversity.com

AWARDS PROGRAMS

- Service Excellence Awards circuitsassembly.com

- NPI Awards circuitsassembly.com

pcdandf.com

DATABASE

- Directory of EMS Companies circuitsassembly.com

mike@pcea.net

frances@pcea.net

brooke@pcea.net

tyler@pcea.net

jacqueline@pcea.net

Clive Ashmore, Peter Bigelow, Robert Boguski, John D. Borneman, John Burkhert, Jr., Stephen Chavez, Mark Finstad, Geoffrey Hazelett, Nick Koop, Geoffrey Leeds, Alun Morgan, Susan Mucha, Greg Papandrew, Chrys Shea, Jan Vardaman, Gene Weiner

frances@pcea.net

brooke@pcea.net

frances@pcea.net

mike@pcea.net

jacqueline@pcea.net

PRINTED CIRCUIT DESIGN & FAB/CIRCUITS ASSEMBLY is distributed without charge to qualified subscribers. To subscribe, visit pcdandf.com or circuitsassembly.com and click on Subscribe.

For changes or cancellations to existing subscriptions: subscriptions@pcea.net

PRINTED CIRCUIT DESIGN & FAB/CIRCUITS ASSEMBLY is published monthly by Printed Circuit Engineering Association, Inc., PO Box 807 Amesbury, MA 01913. ISSN 1939-5442. GST 124513185/ Agreement #1419617.

© 2023, by Printed Circuit Engineering Association, Inc. All rights reserved. Reproduction of material appearing in PRINTED CIRCUIT DESIGN & FAB/CIRCUITS ASSEMBLY is forbidden without written permission.

Add Wisconsin to the List of Failed Foxconn Bettors

THE INK WAS barely dry on the lawsuit filed by Lordstown Motors against would-be savior Foxconn when the next round of news hit: the world’s largest ODM/EMS company is pulling out of Wisconsin.

If we go back to 2019, we will recall Lordstown opening the doors of its plant, formerly owned by GM and seen as critical to its hometown’s economic future, to Foxconn, which came bearing (the promise of) much-needed cash. In return, the ODM was to obtain access to Lordstown’s electric vehicle technology, which Foxconn sought as it reportedly focuses on building electronics and other products for what is seen as the future platform for individual and fleet transportation.

READ FULL ARTICLETrackwise Designs Puts Itself Up for Sale

TEWKESBURY, UK – Trackwise Designs has launched a sales process for its business after reviewing options for the company’s future. The move comes after the printed circuit fabricator lost a major customer.

In mid-July, Trackwise announced that after a year of working with a Tier 1 supplier on the opportunity to supply Cell Connection System flex circuit assemblies, Trackwise was informed by the customer that it had not been successful in securing the business.

READ FULL ARTICLESIA: US Faces Tech Worker Shortage

WASHINGTON – The United States faces a significant shortage of technicians, computer scientists and engineers, with a projected shortfall of 67,000 of these workers in the semiconductor industry by 2030 and a gap of 1.4 million such workers throughout the broader US economy, according to a study released by the Semiconductor Industry Association in partnership with Oxford Economics.

The report, titled “Chipping Away: Assessing and Addressing the Labor Market Gap Facing the U.S. Semiconductor Industry,” also makes a set of policy recommendations to help close the talent gap and complement the workforce development initiatives that are already being carried out by semiconductor companies across the US.

READ FULL ARTICLEChina’s Victory Giant to Buy Singapore’s MFS Technology

HUIZHOU, CHINA – Victory Giant Technology has agreed to buy fellow PCB fabricator MFS Technology for up to $460 million.

Victory Giant will pay cash to acquire Pole Star Ltd. to indirectly own MFS Technology and all its subsidiaries, with equity value worth of about $365 million and debts worth up to $95 million, according to a filing by Victory Giant in the Shenzhen Stock Exchange.

READ FULL ARTICLESanmina Keen on Building Indian Fab Facility

PALO ALTO, CA – Sanmina has reportedly expressed interest in building a PCB fabrication facility in the Indian state of Odisha after a delegation of the state’s officials visited the company in Silicon Valley.

According to India’s Kalinga TV, the Odisha delegation met with Sanmina CEO Jure Sola, senior vice president Sundar Kamath, senior vice president Michael Sparacino, and vice president Bill Pappani to give a detailed presentation on Odisha’s industrial ecosystem to the company’s officials and brief them on the various incentives available under Odisha’s different policies.

READ FULL ARTICLEIPC, PCBAA Seek Clarity on CHIPS Act Plans

BANNOCKBURN, IL – IPC and the Printed Circuit Board Association of America are calling on the US Department of Commerce to clarify its plans for bolstering the domestic development and fabrication of advanced printed circuit boards as a key part of the CHIPS for America program.

In a letter sent to Commerce Secretary Gina Raimondo, IPC president and CEO John W. Mitchell and PCBAA chairman Travis Kelly applauded the “positive signals” that have been sent by the Biden administration regarding greater support for PCBs:

READ FULL ARTICLEShengyi Building $196M Plant in Thailand

DONGGUAN, CHINA – Shengyi Technology, the world’s second-largest seller of copper clad laminate, will invest CNY1.4 billion ($196 million) to establish a new plant in Thailand to meet international clients’ demand for the PCB component.

In a statement, Shengyi said it will purchase a piece of land in an industrial park in Chachoengsao province in south-central Thailand, but it did not disclose the planned annual capacity for the plant or the construction timetable.

READ FULL ARTICLEAltium 365 Integrates with SiliconExpert

SAN DIEGO – Altium has announced an integration collaboration with SiliconExpert, a provider of electronic component data and parts management software, to provide Altium 365 users with direct access to comprehensive, real-time component data whenever it is needed during the design and product lifecycle.

With SiliconExpert’s data on more than 1 billion electronic parts, Altium 365 users can soon access more detailed component information than they have had before, using data sourced directly from manufacturers, which helps ensure accuracy and reliability in decision-making.

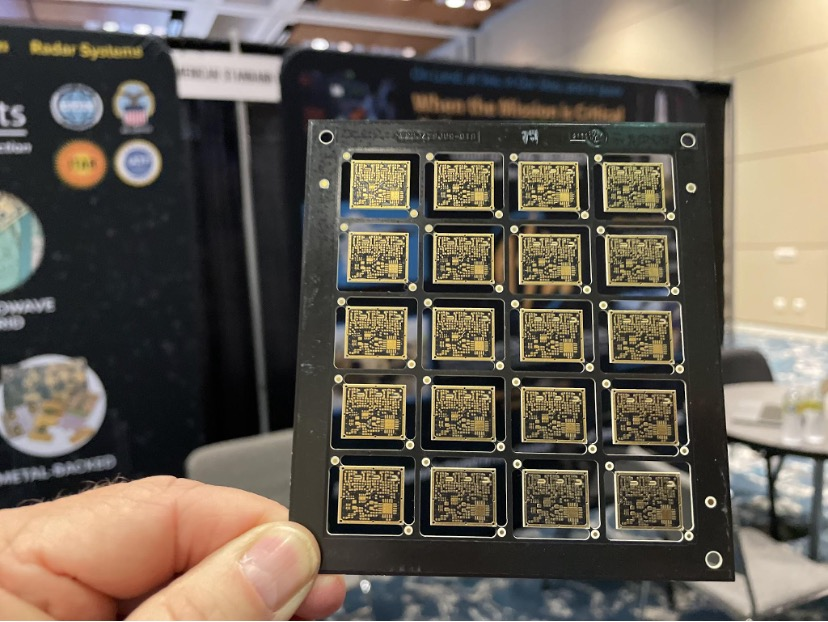

READ FULL ARTICLETechnoprobe Finalizes Harbor Electronics Acquisition

MERATE, ITALY – Technoprobe, an Italian manufacturer of chip testing solutions, has finalized its $50 million acquisition of Harbor Electronics, a California-based PCB maker.

Harbor Electronics, founded in the 1980s in Santa Clara, California and acquired in 2015 by the Shenzhen-headquartered Fastprint Circuit Tech group, is a manufacturer of advanced PCBs for testing systems for major semiconductor manufacturers.

READ FULL ARTICLETeltonika to Build PCB Plant in Lithuanian Capital

VILNIUS, LITHUANIA – Lithuanian company Teltonika has been cleared to build a PCB production plant here. The €143 million ($156 million) plant will be based in the Teltonika High-Tech Hill technology park in the Liepkalnis neighborhood in the capital city.

Teltonika plans to invest €2.1 billion ($2.3 billion) in the Teltonika High-Tech Hill technology park over the next five years.

Power Group Property, part of the Teltonika Group, will carry out the construction, which is planned to be completed in December 2024.

Nano Dimension Acquires Additive Flow Technology

WALTHAM, MA – Nano Dimension has announced the acquisition of the technology and intellectual property of the UK-based company Additive Flow, which supplies solutions for 3-D design simulation and optimization.

Additive Flow has developed high-performance and high-quality simulation software for mechanical, thermal, thermo-mechanical properties, along with frequency and fatigue across a range of materials and processes. Their product addresses design, production, and quality decisions, while optimizing for cost, weight, manufacturing productivity, and manufacturing yield – all simultaneously, Nano Dimension said in a release announcing the acquisition.

READ FULL ARTICLEKingClean Electric Takes Major Stake in PCB Maker

SUZHOU, CHINA – Chinese home appliance maker KingClean Electric plans to acquire a 96.5% stake in PCB maker Suzhou Lihua Technology for 272.5 million yuan ($37.4 million).

Kingclean will buy the stake from Lake Electric Investment Group and RayVal Holding. Suzhou Lihua Technology, established in August 2003, also produces computer and peripheral products.

KingClean said it has decided to acquire Lihua as it is bullish on the global market for electronic products.

Würth Elektronik Completes APPLAUSE Research Project

NIEDERNHALL, GERMANY – Würth Elektronik Circuit Board Technology, along with 31 European partners, have completed the three-year Advanced Packaging for Photonics, Optics, and Electronics for Low-Cost Manufacturing in Europe (APPLAUSE) project, which looked to strengthen the semiconductor value chain for the medical sector in Europe by developing new tools, methods, and processes for volume production.

The project partners consisted of competence leaders from the fields of electronics packaging, optics, and photonics, together with leading equipment manufacturers and medical technology experts. The €34 million ($37 million) project was funded by ECSEL JU (Electronics Components and Systems for European Leadership Joint Undertaking) as part of the Horizon 2020 EU funding program.

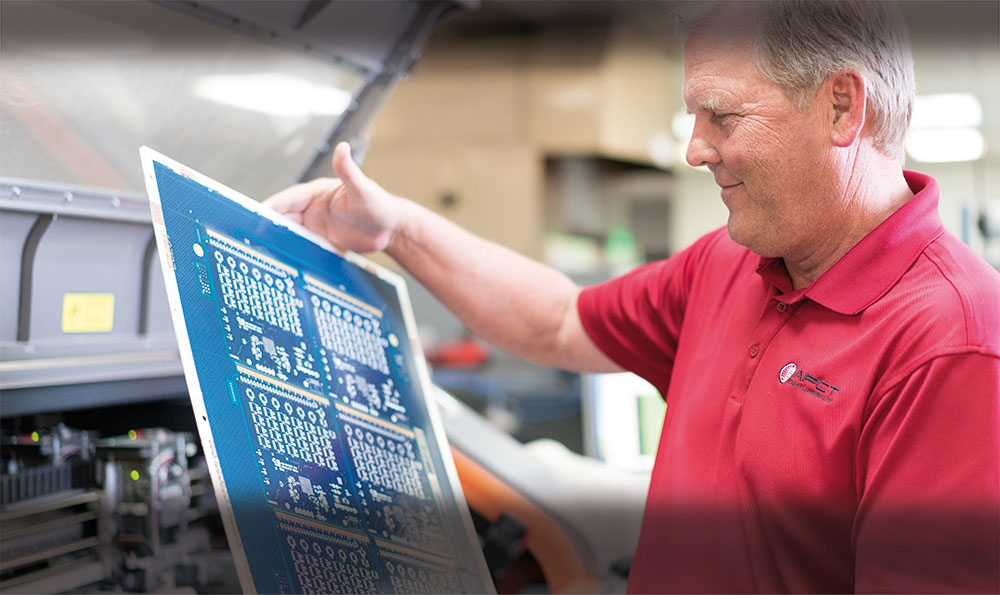

READ FULL ARTICLEAPCT Now Offering Full Turnkey Solutions

SANTA CLARA, CA – Following the acquisitions of Advanced Circuits and San Diego PCB Design earlier this year, APCT has become the second-largest printed circuit manufacturer in North America offering design, fabrication and assembly.

The company’s design team can offer its expertise in a number of design layout services, including standard through-hole, high density interconnect (HDI), signal/power integrity design, dense high- speed digital, and RF & rigid-flex.

The assembly operation is located within the ACI headquarters in Aurora, CO, and is currently only offered as a “value add” to APCT’s customer base. Offerings include both through-hole and surface mount capabilities, supporting prototype quantities of standard technology, with all assembly being completed in-house.

PE Firm to Acquire Humiseal Parent for $1.3B

WESTWOOD, MA – Chase Corporation, a manufacturer of industrial coatings and tapes, has entered into a definitive agreement to be acquired by an affiliate of investment funds managed by investment firm KKR for an all-cash transaction of around $1.3 billion. Chase supplies the Humiseal brand of conformal coatings.

Under the terms of the agreement, KKR will acquire all outstanding shares of Chase common stock for $127.50 per share in cash.

The transaction is expected to close in the fourth quarter of 2023, subject to the receipt of approval from the company’s shareholders and certain required regulatory approvals, as well as the satisfaction of other customary closing conditions.

READ FULL ARTICLEECIA’s GIPC Publishes Cyber Security Guidance Document

ATLANTA – ECIA members face a broad spectrum of cyber risks that could potentially impact their business operations. These risks can be more complex and challenging due to their international scope. In response to these concerns, ECIA’s Global Industry Practices Committee (GIPC) has published a guidance document, prepared as the result of a cooperative effort between electronic component manufacturers and their authorized distributors.

The document outlines key areas that executives need to consider:

READ FULL ARTICLEAdditive Manufacturing Continues to Flourish, Jabil Finds

ST. PETERSBURG, FL – The adoption of 3-D printing continues to increase in production environments despite ongoing roadblocks with the cost and availability of additive materials, according to a survey by Jabil.

Jabil has conducted a biennial survey since 2017 to trace the trajectory of additive manufacturing while identifying the most promising opportunities and lingering challenges facing decision makers.

READ FULL ARTICLETT Electronics Expanding Footprint in Mexico and Malaysia

WOKING, UK – TT Electronics has announced that its Global Manufacturing Solutions business is expanding its footprint in the Americas by opening a new facility in Mexicali, Mexico, and is investing in its Asia Pacific operations to increase capabilities at its existing Kuantan, Malaysia, facility.

“As a strategic manufacturing partner, we have built a solid reputation for delivering agile solutions and excellent customer service,” said Michael Leahan, COO, TT Electronics. “We continue to invest in our global facilities and supply chain resources to directly support customer growth, and we are excited to announce significant expansion to our footprint in our GMS division.”

READ FULL ARTICLEJabil Breaks Ground on Croatian Plant

OSIJEK, CROATIA – Jabil in early August announced that it has begun construction on a production facility here.

The factory will span some 48,000 sq. m. (516,667 sq. ft.) and is scheduled to be completed in July 2024. The finished factory will eventually employ 1,500 workers.

“This project is very important for Osijek, Slavonia and the regional development and will offer numerous opportunities for economic growth and progress,” Victor Morales, head of works, Jabil, in a statement.

READ FULL ARTICLEScanfil to Pump $22M into New Poland EMS Facility

SIERADZ, POLAND – Scanfil will invest €20 million ($22 million) in a new 14,000 sq. m. electronics manufacturing factory here, which will be ready for production in mid-2025.

The new building will increase the factory floor area by over 70%. The project will start this month and is expected to be ready for production in the second quarter of 2025.

The site includes a new building and will require additional investments in production and warehouse technology. Additional investments will be made gradually in line with production volume growth.

READ FULL ARTICLEIMI Sells STI to PE Firm

HOOK, UK – British private equity firm Rcapital has agreed to the purchase of STI Ltd. from Integrated Micro-Electronics for GBP2.2 million ($2.8 million).

After the closing of the acquisition, Rcapital will work on refinancing initiatives for STI that will enable the business to accelerate its growth strategy, at a time when STI’s core aerospace and defense markets are experiencing significant growth, STI said in a release.

READ FULL ARTICLETempo Automation Outsources Manufacturing to Network PCB

SAN FRANCISCO – Financially strapped EMS Tempo Automation has established a manufacturing outsource agreement with Network PCB, a PCB manufacturing and assembly company located in San Jose, CA.

The company laid off 62 of its employees in mid-July, leaving only seven employees on its payroll, while CEO Joy Weiss and CTO Ralph Richart saw their base salaries cut by 50%.

READ FULL ARTICLEKaga Electronics Expanding Mexico Presence

TOKYO – Kaga Electronics will build a new factory in Mexico to meet customers’ growing needs in the US market.

In a release announcing the new construction, Kaga said the purchase of land and construction of the new facility is expected to total around 5 billion yen ($34.2 million) over the next five years. The new facility, which will be built in the Parque Industrial Millennium in San Luis Potosí, will feature 20,000 sq. m. (215,000 sq. ft.) of floor space and when in full operation, the company anticipates a need for 700 employees. Construction is planned to be completed in April 2024.

READ FULL ARTICLEStenTech Acquires Photo Etch Technology

WYLIE, TX – StenTech in August announced the acquisition of stencil manufacturer Photo Etch Technology, along with its affiliate Utz Technologies.

Photo Etch has four locations, with a headquarters in Lowell, MA, and operations in Santa Clara, CA, Clearwater, FL, and Montville, NJ, and the acquisition deepens StenTech’s existing footprint in Silicon Valley and New England while simultaneously extending its reach into Florida through Photo Etch’s Clearwater operation, the company said in a release announcing the acquisition.

READ FULL ARTICLETide Rock Acquires Pro-Active Engineering

SAN DIEGO, CA – Tide Rock, an unlevered buyout firm, has announced the acquisition of Pro- Active Engineering, an EMS solutions provider for the military & defense, industrial, medical, renewable energy and aerospace sectors.

Pro-Active specializes in end-to-end solutions for printed circuit boards, encompassing electronics design, rapid prototyping, short-run and large-scale production, box builds, programming, testing, potting and conformal coating as well as software and firmware development.

READ FULL ARTICLEITIDA, GIZ to Promote Egyptian Offshoring

CAIRO – The Information Technology Industry Development Agency (ITIDA) and the German Agency for International Cooperation (GIZ) have signed a memorandum of understanding to promote Egypt’s offshoring sector and integrate Industry 4.0 digital technologies in local electronics manufacturing.

The focus will be on two pilot clusters, namely the Industry 4.0 Innovation Centre in the Knowledge City, and the Innovation Cluster at Borg El Arab City. The two parties hosted a round table meeting for local and foreign companies specializing in IT outsourcing and global business services to discuss the available growth opportunities, potential partnerships, and means to enhance their operations to help them expand their global delivery centers in Egypt.

READ FULL ARTICLEECIA Publishes Results of Future Workforce Focus Groups

ATLANTA – Winning the race for talent has never been more critical as the entire tech industry faces alarming shortages of skilled workers. To address the challenge, in May and June of 2023, two focus groups were conducted by the Electronic Components Industry Association and its newly established Industry Recruiting Committee.

The objective of the ECIA’s research was to gain insights into what motivates individuals to enter the electronic components industry and to learn how to attract and retain talent, and the research will be used to create strategic marketing collateral for ECIA members to use in recruitment efforts and inform members on best recruitment tactics.

READ FULL ARTICLEPCD&F

Altair was named one of Fortune’s 2023 Best Workplaces for Millennials.

Amphenol agreed to pay $18 million to the federal government to resolve allegations that it submitted false claims for electrical connectors.

Bürkle has divided into four independent divisions to better serve customers.

Flexium Interconnect said the company will focus on maintaining its proDtability in the second half and will strengthen its smart manufacturing capability and management eEciency.

G42 and Cerebras have partnered to build a $100 million AI supercomputer consisting of 64 connected Cerebras CS-2 wafer-scale AI accelerators.

Read Full ArticleCA

Absolute EMS invested in the training of its touchup, quality control, and Dnal quality assurance operators to J-STD-001 Class 3 standards.

Adtran announced the expansion of advanced telecommunications equipment manufacturing at its facility in Huntsville, AL, to meet the growing demand for domestically produced network electronics.

Analog Devices and Foxconn have partnered to work toward the development of the next-generation digital car cockpit and a high-performance battery management system (BMS).

AsteelQash opened a new manufacturing line for Nextracker’s self-powered controller and high-voltage power supply used in solar tracking technology.

BidChip announced its new online platform for buying and selling excess semiconductors.

The EPIC Foundation has signed an MOU with the Andhra Pradesh Electronics and IT Agency with an aim to strengthen the electronics sector in the Indian state.

Read Full ArticlePCD&F

Confidee’s Craig Haywood was approved as an EASA Part 21 Subpart G auditor.

Polar Instruments appointed Lupita Maurer president.

Rogers Corp. named Griffin Gappert chief technology officer.

TTM Technologies announced CFO Todd Schull intends to retire at the end of 2023.

CA

Altus Group appointed Andras Fekete after sales support engineer for Ireland.

Absolute EMS appointed Ray Amirkiai quality manager.

Amtech Systems appointed Bob Daigle CEO.

Escatec appointed Charles-Alexandre Albin chief sales officer.

FHP Reps named Brian Smith manufacturers sales representative.

Frontgate Technologies named Denis Boulanger senior manager, manufacturing engineering.

Read Full ArticleNational News

Designer Certification Program Updates

PEACHTREE CITY, GA – As noted last month, PCEA has closed on the acquisition of the assets of PCBDesign-Edu (PCE-EDU), including its industry leading printed circuit designer training and certification program. The deal extends PCEA’s position as the leading association for training printed circuit engineers worldwide.

We have updated the company name to PCEA Training, rolled out the new website (at pceatraining.net) and revealed the new logo.

We have updated the company name to PCEA Training, rolled out the new website (at pceatraining.net) and revealed the new logo.

Chapter News

Silicon Valley. The chapter held a meeting on Aug. 30. The technical topic was Leveraging Advanced Technologies to Accelerate Electronic Systems Design, and the speaker was David Wiens, Xpedition product manager, Siemens.

PCB Outlook for 2023 Mixed, but Slow

TAIPEI – The printed circuit board industry endured customer inventory adjustments in the second quarter, mostly due to lower demand. Sales of consumer electronics, such as TVs, laptops, memory modules and wearables have stabilized and cellphone demand typically rises in the third quarter in the US, although the Chinese market has not yet improved. Still, the inventory problems of the past year have in general returned to healthier levels, but under the haze of inflation, consumption is still conservative, and a modest recovery is expected for the second half.

READ FULL ARTICLEDon’t Forget the People

An unchecked rise in automation could equal a decrease in quality of life.

THEY SAY THAT the more things change the more they stay the same. Sometimes, perhaps, but not all the time – especially when people are involved.

For ages, people have strived for a good lifestyle. In ancient times, simply surviving – literally – might have been the definition of a good lifestyle. Over time, the definition has pivoted, influenced by the times in which people were living. For over a hundred years, people took both the short- and long-term view when defining their lifestyle. Short term, the idea was to have a good job, one that paid as well as possible, provided upward potential for both compensation and responsibility while also offering a level of stability, so one did not have to worry every day, week or month “if” they would have that job.

Most in our industry entered it because they saw a potential for growth – personal growth, as well as growth for the organization with which they were working. Most also started in an entry-level position and through hard work, observation and learning, could either become an expert in the area or on the equipment/process they operate, or be promoted to managing process, people or both. And while living in this short-term lifestyle called a career, people also built a life that in the long term provided a comfortable and happy environment for themselves and their family. Some call this the American dream, but I view it as a global vision, one shared by citizens around the world.

Read Full ArticleThere is No Drop-in Replacement for China PCB Manufacturing – Yet

Observations from Malaysia and Thailand.

THERE HAS BEEN a push of late by many OEM and EMS companies in the PCB industry – intensified by Covid and simmering trade and political tensions – to reduce the West’s reliance on China for printed circuit board manufacturing.

In the past year, several of our customers, primarily from OEMs in the automotive, RF and testing industries, have asked for an “Out of China” or “China+1” strategy.

These customers have been buying boards from China for years for products or technology that does not fall under any export control.

So why the change now?

Read Full ArticleSurviving the Rush to Tape Out the Printed Circuit Board

Design constraints often morph with lessons learned from the prototype.

CAN WE JUST assume that every board design is going to be a nonlinear effort? While we know that everything is subject to change except the tape-out date, there are a few ways we can taxi toward the runway of product launch.

Today’s supply chain is tighter than the one in the textbooks on product management. The printed circuit boards are often in the critical path, whether they are test jigs for prototypes or the final mass-production units. A schedule slip on P1 cascades to P2 and everything gets compressed. Execution is essential. Otherwise, we won’t have time to learn the lessons of the first iteration before committing to the next.

Take Design Automation Along for the Ride

It’s far past time to use the complete power of the tool to your advantage.

DESIGN AUTOMATION IS one of my favorite topics. When I think of design automation, what first comes to mind are three words: optimization, efficiency and speed. Some design engineers and layout professionals are reluctant to learn new technology to design better, faster and more efficiently in the quest for delivering a quality product to market at the lowest engineering and manufacturing cost. Earlier in my career, I too was reluctant to give in to automation when it came to designing PCBs. I recall, about 20 years ago, I was under a typical project deadline in the project design cycle. You know what I’m talking about: “We need it done today! Oh, and by the way, we have more design changes for you to implement, but we still need it completed and released today!”

It was during that type of project for a specific aerospace customer where I made the decision to use automation to route signal traces. For the first time in my career, I used the autorouting feature in my tool. Talk about an uneasy feeling, like a stomach cramp. It was gut-wrenching to let go of my manual approach for designing PCBs, especially knowing I was under a very stressful and tight project time constraint. In the end, and to my surprise and amazement, I managed to successfully implement autorouting. By doing so, I managed to finish earlier than expected, which shocked the EE I was working with, along with everyone else on the project … and I came in with several alternate versions of the same design for the EE to choose from. Success! What a feeling! One of the highlights of my career, for sure. I have never looked back. To this day, more than ever, I stress harnessing the horsepower of the CAD tools and using their capabilities to your advantage.

Read Full ArticleModels Can Be Deceiving: Trust, but Verify

Numbers on a data sheet are a good start, but confirm them with your own testing.

“TRUST, BUT VERIFY.” While some readers will recall hearing this in the context of nuclear disarmament, I have it most notably drilled into my conscience by my first engineering manager while working in software quality assurance. And for good reason too! It was literally my role to verify the fixes that the engineers claimed they had implemented and to find the issues that were still open. While most of the time their fixes resolved the issue, sometimes it was only partially dispositioned.

So how do we successfully trust, but verify when it comes to information in data sheets for not just copper roughness, but other values significant for modeling signal integrity in printed circuit boards?

In a previous column, I discussed copper roughness and a partial story of the lifecycle of the copper as it moves along in the process of becoming part of a printed circuit board. In that article, I mentioned the dielectric constant/permittivity (Dk) and the dissipation factor/loss tangent (Df) of the resin/filler/glass combination. The data sheets used to be very secretive, with material suppliers concerned about corporate espionage regarding chemistries if the Dk and Df information was made publicly available. Depending on the material supplier and the materials in question, many times one can also find the construction data – glass weave style and quantity, resin content, and shelf thickness.

Read Full ArticleThe Cost of Reshoring

The rebalancing of high-tech power must involve the entire supply chain – and will increase prices for everyone.

ADVANCED TECHNOLOGY IS an important instrument of power on the world stage. Arguably more than at any previous time in history, it’s closely linked to economic influence, energy generation and management, healthcare delivery, international diplomacy, and military strength including cyber capabilities. Access to advanced technology is the issue at the heart of the current maneuvering between western nations and China, in particular.

Concerned about the potential for Chinese control over its communication networks, the West has restricted involvement in 5G infrastructure projects. It’s currently limiting shipments of advanced industrial technology. Of course, China has responded, announcing export controls on raw materials like gallium and germanium, which are basic ingredients for producing compound semiconductors: a critical enabling technology for future generations of equipment such as optical networking, 5G infrastructure, and high-efficiency power conversion needed to ensure affordable renewable energy and e-mobility.

Read Full Article3-D Printing of Plastic Structures onto PCBs for Circuit Protection Strategies

A design, equipment, process and materials methodological approach.

by STANTON F. RAK and DAVID TSEUNG

Electronics for automotive applications, as well as for other industries, are expected to reliably operate in harsh environments at a competitive cost. Advances in safety, communication and displays are driving miniaturization and integration of sub-devices onto the PCB assembly; e.g., cameras, sensors, and LEDs. Electrification trends are also leading to higher voltage requirements. In one example of a harsh environment application, automotive door and window control modules may have a critical circuit or component that is desired to function for a specified amount of time, even while submerged in water.

This paper describes an enabling technology to assist in the protection of critical functionality on PCB assemblies. 3-D-printed plastic retaining or “barrier” walls are formed to precisely control the location and height of a dispensed encapsulant in a region of the circuit that is sensitive to the environment. A case study was undertaken for the creation of 3-D-printed retaining walls, formed directly onto the surface of PCB substrates, without the need for separate parts, mold tools, mechanical or liquid fasteners, and complex manufacturing equipment. Also eliminated is the need to encapsulate or pot the entire PCB assembly, which adds additional complexity and cost. The encapsulant-filled retaining wall structure protects critical circuits from chemical, mechanical and electrical external factors such as moisture, fluids, gasses, particulate contamination, physical contact, or arcing in applications requiring high voltage. A 3-D model of the SIR test PCB having a representative retaining wall structure, surrounding an interdigitated test circuit, is shown in FIGURE 1. The retaining walls hold a liquid-dispensed encapsulant in place, at a predetermined height. In the absence of a retaining wall structure, as shown in FIGURES 2 and 3, an encapsulate can spread uncontrollably across the surface of the PCB (Figure 2), or result in insufficient height of the encapsulant, exposing electronics circuitry (Figure 3).

Read Full ArticleShow Them the Money

Compensation continues to rise among PCB designers.

by TYLER HANES

After last year saw an explosion in printed circuit designers and design engineers reporting salaries above $150,000, this year’s survey conducted by PCD&F/CIRCUITS ASSEMBLY found an even higher number, with 22% reporting their salaries in that range, compared to 19% in 2022.

The percentage of designers making more than $100,000 annually also rose from last year’s results, with 55% in 2023 compared to 35% last year, and around 83% of designers reported receiving raises over the past year.

PCD&F/CIRCUITS ASSEMBLY surveyed designers and design engineers this year from mid-July to Aug. 23. More than 170 designers responded to the survey, answering questions related to job titles and functions, ages, years of experience, education, location, types of projects, annual salaries and sales, job satisfaction and challenges, ECAD tools used, and years left in the field.

Read Full ArticleClosed-Loop Process Optimization between Screen Printer and SPI in an SMT Line

An experiment investigating print alignment adjustments.

by MIGUEL ARROYO COLOMER, CSMTPE

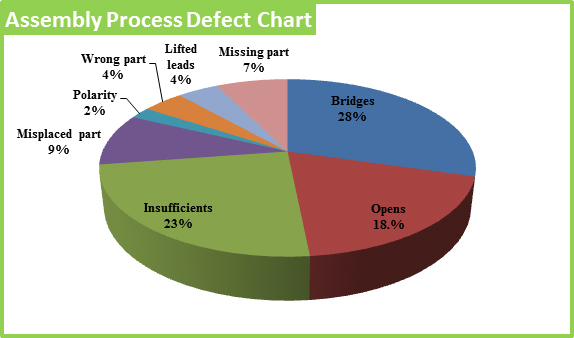

Printed circuit board assembly requires extraordinary precision and repeatability. The screen printing process is considered the most critical process in the surface mount technology (SMT) assembly process. According to some studies, 70% of SMT defects can be traced back to the screen printing process (FIGURE 1). Component miniaturization has made this process more critical. Therefore, alignment of the apertures in the screen or stencil is key to an efficient and accurate solder paste transfer and there isn’t such a thing as local offset.

Every new generation of screen printers is more precise and repeatable than the previous one. External factors that cannot be controlled, however, affect the solder paste deposited on the PCBA’s solder pads. One of these factors is the stencil or board stretching. The solder brick (FIGURE 2) (e.g., the area of solder paste deposited or printed onto the printed circuit board) can be right on the solder pads in one area of the PCBA, yet off in another. It is for this reason that, sometimes, print offsets are required. This is a manual process that is performed one time. The solder paste brick could be overhanging from its solder pad if there is stencil and/or PCBA variation (stretching).

Read Full ArticleThe Power of Personal Branding: Creating an Authentic and Sustainable Perception

Learn from successful entrepreneurs and specialists at the annual Women’s Leadership Program.

by PRIYANKA DOBRIYAL, PH.D.

We can find heroes all around us, but we will challenge you to look inside yourself and to not only identify your superpower but give you some tools to help define your personal brand. So, pick up your cape at the cleaners in time for the SMTA’s Women’s Leadership Conference at SMTA International. Show your support for diversity in engineering fields by joining usas we soar, explore and discover our very own Superheroes. The event is scheduled for Oct. 9 at the Minneapolis Convention Center.

A frequently discussed subject among cohorts and mentoring sessions is personal branding. And if you are assigned the duty of developing content centered around it, you could spend a considerable amount of time researching and reflecting on the fundamental aspects of this topic, as well as the genuine methods to build it. Hence, when the SMTA Women’s Leadership Program (WLP) team chose to focus on the theme of personal branding for the 2023 session, we dedicated some time to create and offer tips for beginners on its development. We pinpoint three notable attributes for an authentic and compelling personal brand:

- Launching your personal brand rooted in core values

- Continuously adapting and refining the brand as your profile evolves and changes

- Implementing strategic approaches to establishing and promoting your brand.

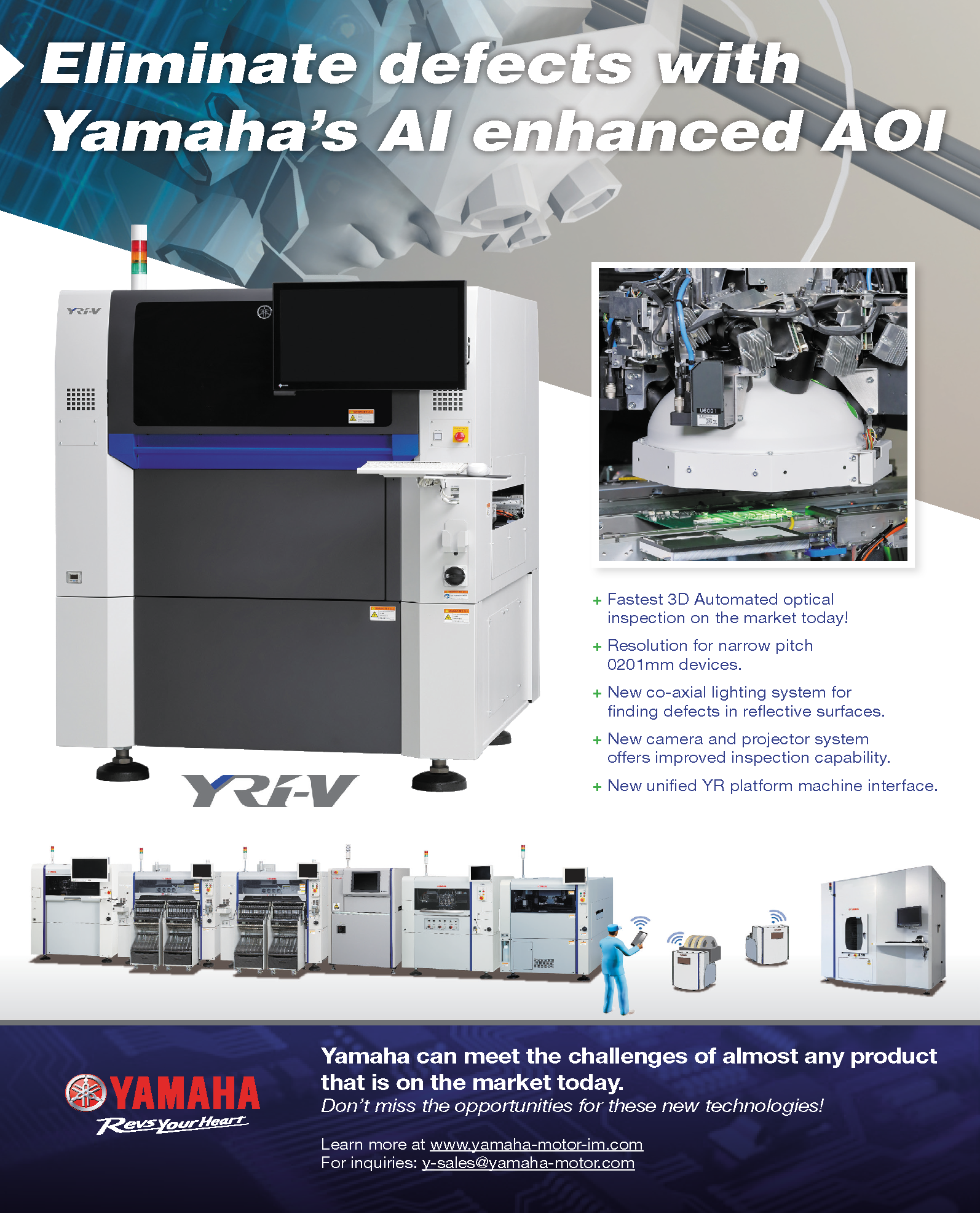

Continuous Improvement and Mass Inspection

Automating inspection in secondary assembly operations.

ONE OF THE first lessons in quality management is the difference between quality assurance and quality control. Quality assurance focuses on eliminating defect opportunities before they occur, while quality control focuses on inspection strategies that eliminate defects before they escape the factory. There is universal agreement that quality assurance is more cost effective than quality control. Lean manufacturing principles are based on a quality assurance focus. That said, use of automated inspection equipment has been growing dramatically in recent years because increasing density and complexity in printed circuit board assemblies (PCBAs) is driving the need for a blended quality assurance/quality control approach that includes mass inspection.

Over the past 18 months, SigmaTron International’s facility in Tijuana, Mexico, has been exploring the best way to automate inspection and integrate the captured data into real-time corrective action throughout its entire PCBA assembly process. A July 2022 PCD&F/CIRCUITS ASSEMBLY column, “An Industry 4.0 Approach to Employing 3-D AOI on an SMT Line,” discussed the journey of integrating Industry 4.0 capabilities in a Lean Six Sigma framework in this facility’s SMT area. Once that phase was completed, implementation of 3-D AOI capability began in secondary assembly work cells. Typical secondary assembly operations include soldering cables and components such as switches which can’t be reflowed, adding rubber caps and placing QR labels.

Read Full ArticleDriving Fast, Caring Not a Whit

Lessons learned from dealing with “the most important guys in the room.”

“Move fast and break things.” – Attributed to Mark Zuckerberg

THIS MORNING, ON my inbound commute, I stopped at a red light. I stopped just in time to see an expensive-looking SUV turn, oblivious to oncoming traffic, into my lane from the crossroad. It accelerated rapidly in the same direction I was traveling. Really rapidly. Propelled like a medical emergency. An impending birth, perhaps? This anxious vehicle exuded affluence. It was coming from the venture capital side of the Bay. Perhaps headed east to merge and acquire. It had that private equity look to it. You know the kind. Maybe the driver was late for surgery, living out his college-age nightmare in real time. Or he forgot his online bank account password, and, in an instant of thoughtless panic, was racing to make an in-person withdrawal from an almost-shuttered Silicon Valley funding source. Not to name names. Whatever the impetus, they drive with. Because they can. Nobody ever told them “No.”

Important guys (invariably guys) having to be at important places, doing important work. Get out of my way.

Progressive politics notwithstanding, our region suffers from delusions of permanent adolescence.

Read Full Article

PCD&F

3D SYSTEMS ACCURA AMX SLA MATERIAL

Accura AMX Tough FR V0 Black 4ame-retardant material for stereolithography is also available as Figure 4 Tough FR V0 Black for use with 3D Systems’ Figure 4 platform. Delivers enhanced part quality and resolution for SLA previously only achievable with selective laser sintering (SLS) and fused deposition modeling (FDM) technologies. Achieves UL 94 V0 rating and features a combination of 4exural modulus and unmatched elongation at break of nearly 35%, which combine with long-term stability to make the material ideal for applications such as printed circuit board covers, semiconductor equipment, electrical housing, covers, hangers, brackets, and 4ame- retardant parts for trains and buses.

3D Systems

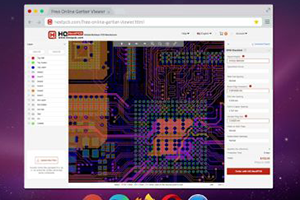

HQ NEXTPCB HQDFM GERBER VIEWER

HQDFM Gerber Viewer and DfM Analysis Tool is a free online tool for displaying and reviewing PCB Gerber Xles and OBD++ Xles. Incorporates NextPCB’s design for manufacture algorithms and allows designers to navigate and analyze production Xles and check for design issues that may impact manufacturing or cause long-term reliability issues. Based on the free desktop software HQDFM and available to anyone, including Mac and Linux users, with no download or install and no signup.

HQ NextPCB

CA

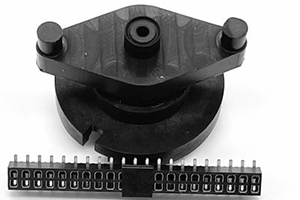

COUNT ON TOOLS 2023-5260 VACUUM NOZZLE

2023-5260 specialized vacuum nozzle is designed to handle all types of odd-shaped components with unmatched precision. Is paired with two outlying supports to offer exceptional accuracy and consistency during the placement process, allowing customers to effortlessly and reliably place the challenging SKT108775GQS header – a feat that previously reliedon a manual hand placement process.

Count On Tools

HERAEUS PTC4900 HEATER INKS

PTC4900 series self-regulating heater inks offer enhanced performance, expanded operating temperatures, and additional customization options. Designed for precise temperature control and are suitable for various applications, including EV battery heaters, ADAS heaters, 4ooring heaters and cabin comfort heaters. Target heater operating temperatures between 50°-90°C, with products targeting temperatures above 100°C currently in development. Permits precise heating with self- regulating properties, eliminating time-consuming adjustments and permitting wider process windows.

Heraeus Electronics

In Case You Missed It

Characteristic Impedance

“Identifying and Modeling Resonance-Related Fluctuations on the Experimental Characteristic Impedance for PCB and On-Chip Transmission Lines”

Authors: Yojanes Rodríguez-Velásquez, Reydezel Torres-Torres and Roberto Murphy-Arteaga

Abstract: It is well known that the fluctuations in experimentally obtained characteristic impedance versus frequency curves are associated with resonances originated by standing waves bouncing back and forth between the transitions at the transmission line terminations. In fact, microwave engineers are aware of the difficulty to completely remove the parasitic effect of these transitions, which makes obtaining smooth and physically expected frequency-dependent curves for the characteristic impedance a tough task. Here, the authors point out for the first time that these curves exhibit additional fluctuations within the microwave range due to standing waves taking place within the transition itself. Experimental verification of this fact was carried out by extracting this fundamental parameter from measurements performed on on-chip and printed circuit board (PCB) lines using probe pad adapters and coaxial connectors. The authors demonstrate that the lumped circuit approach to represent the transitions lacks validity when the additional fluctuations due to the connectors become apparent, and we propose a new model including transmission line effects within the transition. (Electronics, July 2023, https://doi.org/10.3390/electronics12132994)

Read full article